Prediction Primary Available Blend Biodiesel of Waste Oil from Aurantiochytrium sp. for General Diesel Engines

Keywords:

waste oil, Aurantiochytrium sp., biodiesel, winterization, blend biodieselAbstract

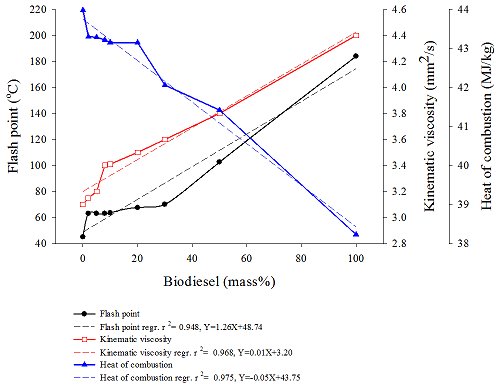

Chemical and enzyme transesterification were compared by discussing preliminary transesterification of waste oil of Aurantiochytrium sp., which was then used in transesterification for the primary available blend biodiesel for a general diesel engine in this study. We made progress on the winterized characteristics of the waste oil’s biodiesel of Aurantiochytrium sp. and its biodiesel, which included the reactivity parameters and properties. This approach led to the development of a novel idea for the evaluation of kinetic parameters of winterization, along with obtaining the suitable operation and storage conditions of biodiesel. Therefore, the waste oil of Aurantiochytrium sp. could be developed for biodiesel production and successfully made into a suitable blend diesel. Overall, we acquired the best condition of mixtures and the highly mixed rate of petrodiesel: biodiesel = 80 : 20 (activation energy of winterization 21.32 kJ/mol; onset temperature of winterization -4.15 °C; heat of combustion 43.15 MJ/kg; kinematic viscosity 3.51 mm2/s; flash point 67.5 °C), which was an appropriate blend biodiesel from the waste oil’s biodiesel of Aurantiochytrium sp.

References

S. Y. Tsai, H. Y. Lin, G. Y. Lu, and C. P. Lin, “Solid byproducts of Aurantiochytrium sp. oil made into the biodiesel oil made into the biodiesel,” Journal of Thermal Analysis and Calorimetry, vol. 120, no. 1, pp. 563-572, April 2015.

J. Wang, L. Cao, and S. Han, “Effect of polymeric cold flow improvers on flow properties of biodiesel from waste cooking oil,” Fuel, vol. 117, pp. 876-881, January 2014.

A. Hayyan, M. A. Hashim, M. E. Mirghani, M. Hayyan, and I. M. Alnashef, “Esterification of sludge palm oil using trifluoromethane sulfonic acid for preparation of biodiesel fuel,” Korean Journal of Chemical Engineering, vol. 30, no. 6, pp. 1229-1234, June 2013.

S. K. Hoekman, A. Broch, C. Robbins, E. Ceniceros, and M. Natarajan, “Review of biodiesel composition, properties, and specifications,” Renewable and Sustainable Energy Reviews, vol. 16, no. 1, pp. 143-169, January 2012.

X. Meng, J. Yang, X. Xu, L. Zhang, Q. Nie, and M. Xian, “Biodiesel production from oleaginous microorganisms,” Renewable Energy, vol. 34, no. 1, pp. 1-5, January 2009.

J. V. Gerpen, “Biodiesel processing and production,” Fuel Processing Technology, vol. 86, no. 10, pp. 1097-1107, June 2005.

P. Sivakumar, K. Anbarasu, and S. Renganathan, “Bio-diesel production by alkali catalyzed transesterification of dairy waste scum,” Fuel, vol. 90, no. 1, pp. 147-151, January 2011.

M. Xiao, S. Mathew, and J. P. Obbard, “Biodiesel fuel production via transesterification of oils using lipase biocatalyst,” Global Change Biology Bioenergy, vol. 1, no. 2, pp. 115-125, April 2009.

N. Sangaletti, M. Cea, M. A. B. Regitano-d’Arce, T. M. F de Souza Vieirac, and R. Navia, “Enzymatic transesterification of soybean ethanolic miscella for biodiesel production,” Journal of Chemical Technology and Biotechnology, vol. 88, no. 11, pp. 2098-2106, November 2013.

F. Hasan, A. A. Shah, and A. Hameed, “Industrial applications of microbial lipases,” Enzyme and Microbial Technology, vol. 39, no. 2, pp. 235-251, June 2006.

M. Aarthya, P. Saravananb, M. K. Gowthamana, C. Rosea, N. R. Kaminia, “Enzymatic transesterification for production of biodiesel using yeast lipases: an overview,” Chemical Engineering Research and Design, vol. 92, no. 8, pp. 1591-1601, August 2014.

R. Abdulla, and P. Ravindra “Immobilized Burkholderia cepacia lipase for biodiesel production from crude Jatrophacurcas L. oil,” Biomass and Bioenergy, vol. 56, pp. 8-13, September 2013.

A. Guldhe, B. Singh, T. Mutanda, K. Permaul, and F. Bux, “Advances in synthesis of biodiesel via enzyme catalysis: Novel and sustainable approaches,” Renewable and Sustainable Energy Reviews, vol. 41, pp. 1447-1464, January 2015.

T. C. Kuo, J. F. Shaw, and G. C. Lee, “Conversion of crude Jatropha curcas seed oil into biodiesel using liquid recombinant Candida rugosa lipase isozymes,” Bioresource Technology, vol. 192, pp. 54-59, September 2015.

X. Fang, Y. Zhan, J. Yang, and D. Yu, “A concentration-dependent effect of methanol on Candida antarctica lipase B in aqueous phase,” Journal of Molecular Catalysis B: Enzymatic, vol. 104, pp. 1-7, June 2014.

S. Y. Tsai, W. S. Tseng, C. T. Wu, and C. P. Lin, “Dwarf-castor oil made into a suitable biodiesel,” Procedia Engineering, vol. 84, pp. 940-947, 2014.

C. P. Lin and J. M. Tseng, “Green technology for improving process manufacturing design and storage management of organic peroxide,” Chemical Engineering Journal, vol. 180, pp. 284-292, January 2012.

G. B. Wang, C. C. Chen, H. J. Liaw, Y. J. Tsai, “Prediction of flash points of organosilicon compounds by structure group contribution approach,” Industrial & Engineering Chemistry Research, vol. 50, no. 22, pp 12790-12796, September 2011.

Cannon-Fenske Opaque Viscometers, CANNON Instrument Company, 2014, www.cannoninstrument.com.

ASTM D6751, Standard specification for biodiesel fuel blend stock (B100) for middle distillate fuels, ASTM International, West Conshohocken, PA, 2015, www.astm.org.

Parr Bulletin 1341, Plain jacket calorimeter, Parr Instrument Co., Moline, IL, 1977.

A. M. Halpern, G. C. McBane, Experimental physical chemistry. 3rd ed., New York: Freeman, W. H., pp. 5.1-5.15, 2006.

A. S. Gundogar and M. V. Kok, “Thermal characterization, combustion and kinetics of different origin crude oils,” Fuel, vol. 123, pp. 59-65, May 2014.

F. Gasparini, J. R. de O. Lima, Y. A. Ghani, R. R. Hatanaka, R. Sequinel, D. L. Flumignan, and J. E. de Oliveira, “EN 14103 adjustments for biodiesel analysis from different raw materials, including animal tallow containing C17,” World Renewable Energy Congress 2011, Bioenergy Technology, May, 2011, pp. 101-108.

G. Knothe, “Analyzing biodiesel: standards and other methods,” Journal of the American Oil Chemists' Society, vol. 83, no. 10, pp 823-833, October 2006.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.