Wetting-Drying Durability of Lateritic Soil Stabilized with One-Part High-Calcium Fly Ash Geopolymer

DOI:

https://doi.org/10.46604/peti.2024.14224Keywords:

durability, solid sodium hydroxide, marginal lateritic soil, fly ashAbstract

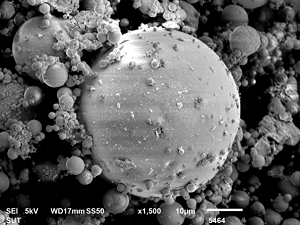

This study investigates the durability under wetting and drying conditions of marginal lateritic soil (MLS) stabilized with a one-part high-calcium fly ash geopolymer (OPFAG). The variables include an MLS: fly ash ratio of 70:30, solid sodium hydroxide content ranging from 0 to 40%, and the number of wet-dry cycles. Durability is evaluated by measuring the unconfined compressive strength (UCS) of MLS samples stabilized with OPFAG and MLS samples stabilized with ordinary Portland cement (OPC). The results show that OPFAG improved the engineering properties of MLS. The highest UCS values are achieved at 20% solid sodium hydroxide, achieving a UCS of 1889 kPa for the geopolymer-stabilized MLS and at 5% OPC for OPC-stabilized MLS (1320 kPa). The UCS of both stabilized MLS samples increases with the number of wet-dry cycles up to 6 cycles, after which a decline is observed.

References

P. Prus and M. Sikora, “The Impact of Transport Infrastructure on the Sustainable Development of the Region—Case Study,” Agriculture, vol. 11, no. 4, article no. 279, 2021.

S. Caro, J. P. Agudelo, B. Caicedo, L. F. Orozco, F. Patiño, and N. Rodado, “Advanced Characterisation of Cement-Stabilised Lateritic Soils to Be Used as Road Materials,” International Journal of Pavement Engineering, vol. 20, no. 12, pp. 1425-1434, 2019.

T. A. Pham, J. Koseki, and D. Dias, “Optimum Material Ratio for Improving the Performance of Cement-Mixed Soils,” Transportation Geotechnics, vol. 28, article no. 100544, 2021.

Utkarsh and P. K. Jain, “Enhancing the Properties of Swelling Soils with Lime, Fly Ash, and Expanded Polystyrene -A Review,” Heliyon, vol. 10, no. 12, article no. e32908, 2024.

Utkarsh and P. K. Jain, “A Review on Innovative Approaches to Expansive Soil Stabilization: Focussing on EPS Beads, Sand, and Jute,” Science and Engineering of Composite Materials, vol. 31, no. 1, article no. 20240005, 2024.

Utkarsh and P. K. Jain, “Predicting Bentonite Swelling Pressure: Optimized XGBoost Versus Neural Networks,” Scientific Reports, vol. 14, article no. 17533, 2024.

Z. Hu, Y. Wang, and C. Wang, “Study on Mechanical Properties of Dredged Silt Stabilized with Cement and Reinforced with Alginate Fibers,” Case Studies in Construction Materials, vol. 18, article no. e01977, 2023.

N. Jiang, C. Wang, Z. Wang, B. Li, and Y. A. Liu, “Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume,” Materials, vol. 14, no. 8, article no. 1929, 2021.

C. Suksiripattanapong, S. Horpibulsuk, C. Yeanyong, and A. Arulrajah, “Evaluation of Polyvinyl Alcohol and High Calcium Fly Ash Based Geopolymer for the Improvement of Soft Bangkok Clay,” Transportation Geotechnics, vol. 27, article no. 100476, 2021.

W. Tabyang, C. Suksiripattanapong, C. Phetchuay, C. Laksanakit, and N. Chusilp, “Evaluation of Municipal Solid Waste Incineration Fly Ash Based Geopolymer for Stabilised Recycled Concrete Aggregate as Road Material,” Road Materials and Pavement Design, vol. 23, no. 9, pp. 2178-2189, 2022.

W. Tabyang, T. Kuasakul, P. Sookmanee, C. Laksanakit, N. Chusilp, Y. Bamrungphon, et al., “Use of a Rubber Wood Fly Ash-Based Geopolymer for Stabilizing Marginal Lateritic Soil as Green Subbase Materials,” Clean Technologies and Environmental Policy, vol. 26, no. 6, pp. 2059-2073, 2024.

C. Suksiripattanapong, R. Sakdinakorn, S. Tiyasangthong, N. Wonglakorn, C. Phetchuay, and W. Tabyang, “Properties of Soft Bangkok Clay Stabilized with Cement and Fly Ash Geopolymer for Deep Mixing Application,” Case Studies in Construction Materials, vol. 16, article no. e01081, 2022.

P. Yoosuk, C. Suksiripattanapong, P. Sukontasukkul, and P. Chindaprasirt, “Properties of Polypropylene Fiber Reinforced Cellular Lightweight High Calcium Fly Ash Geopolymer Mortar,” Case Studies in Construction Materials, vol. 15, article no. e00730, 2021.

P. Yoosuk, C. Suksiripattanapong, G. Hiroki, T. Phoo-ngernkham, J. Thumrongvut, P. Sukontasukkul, et al., “Performance of Polypropylene Fiber-Reinforced Cellular Lightweight Fly Ash Geopolymer Mortar Under Wet and Dry Cycles,” Case Studies in Construction Materials, vol. 20, article no. e03233, 2024.

T. Tesanasin, C. Suksiripattanapong, B. Van Duc, W. Tabyang, C. Phetchuay, T. Phoo-ngernkham, et al., “Engineering Properties of Marginal Lateritic Soil Stabilized with One-Part High Calcium Fly Ash Geopolymer as Pavement Materials,” Case Studies in Construction Materials, vol. 17, article no. e01328, 2022.

T. Tesanasin, C. Suksiripattanapong, T. Kuasakul, T. Thongkhwan, W. Tabyang, J. Thumrongvut, et al., “Comparison Between Cement-Rice Husk Ash and Cement-Rice Husk Ash One-Part Geopolymer for Stabilized Soft Clay as Deep Mixing Material,” Transportation Infrastructure Geotechnology, vol. 11, no. 4, pp. 1760-1776, 2024.

J. Widjajakusuma, I. Bali, G. P. Ng, and K. A. Wibowo, “An Experimental Study on the Mechanical Properties of Low-Aluminum and Rich-Iron-Calcium Fly Ash-Based Geopolymer Concrete,” Advances in Technology Innovation, vol. 7, no. 4, pp. 295-302, 2022.

W. T. Lin, K. L. Lin, K. Korniejenko, and L. Fiala, “Comparative Analysis Between Fly Ash Geopolymer and Reactive Ultra-Fine Fly Ash Geopolymer,” International Journal of Engineering and Technology Innovation, vol. 11, no. 3, pp. 161-170, 2021.

J. Wu, Y. Min, B. Li, and X. Zheng, “Stiffness and Strength Development of the Soft Clay Stabilized by the One-Part Geopolymer Under One-Dimensional Compressive Loading,” Soils and Foundations, vol. 61, no. 4, pp. 974-988, 2021.

K. Pławecka, P. Bazan, W. T. Lin, K. Korniejenko, M. Sitarz, and M. Nykiel, “Development of Geopolymers Based on Fly Ashes from Different Combustion Processes,” Polymers, vol. 14, no. 10, article no. 1954, 2022.

P. Ghadir and N. Ranjbar, “Clayey Soil Stabilization Using Geopolymer and Portland Cement,” Construction and Building Materials, vol. 188, pp. 361-371, 2018.

T. Luukkonen, Z. Abdollahnejad, J. Yliniemi, P. Kinnunen, and M. Illikainen, “One-Part Alkali-Activated Materials: A Review,” Cement and Concrete Research, vol. 103. pp. 21-34, 2018.

ASTM International, Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils, ASTM D4318-17, 2017.

ASTM International, Standard Test Method for Density of Hydraulic Cement, ASTM C188-95, 1995.

ASTM International, Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete, ASTM C618-19, 2019.

ASTM International, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)), ASTM D1557-12, 2021.

ASTM International, Standard Test Method for Unconfined Compressive Strength of Cohesive Soil, ASTM D2166-06, 2006.

ASTM International, Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures, ASTM D559/D559M-15, 2015.

T. P. Ngo, Q. B. Bui, V. T. A. Phan, and H. B. Tran, “Durability of Geopolymer Stabilised Compacted Earth Exposed to Wetting–Drying Cycles at Different Conditions of pH and Salt,” Construction and Building Materials, vol. 329, article no. 127168, 2022.

X. T. Xu, L. J. Shao, J. B. Huang, X. Xu, D. Q. Liu, Z. X. Xian, et al., “Effect of Wet-Dry Cycles on Shear Strength of Residual Soil,” Soils and Foundations, vol. 61, no. 3, pp. 782-797, 2021.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Tavorn Kuasakul, Teerat Tesanasin, Sermsak Tiyasangthong, Komkorn Chaidachatorn, Nattiya Wonglakorn, Wisitsak Tabyang, Cherdsak Suksiripattanapong

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright of their article with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Oct. 01, 2015, PETI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes