Quantifying the Influence of Surface Roughness on Concrete Overlay Bonding in Sulfuric Acid Environments

DOI:

https://doi.org/10.46604/peti.2024.14713Keywords:

sulfuric acid, surface roughness, bonding strength, mass loss, UPVAbstract

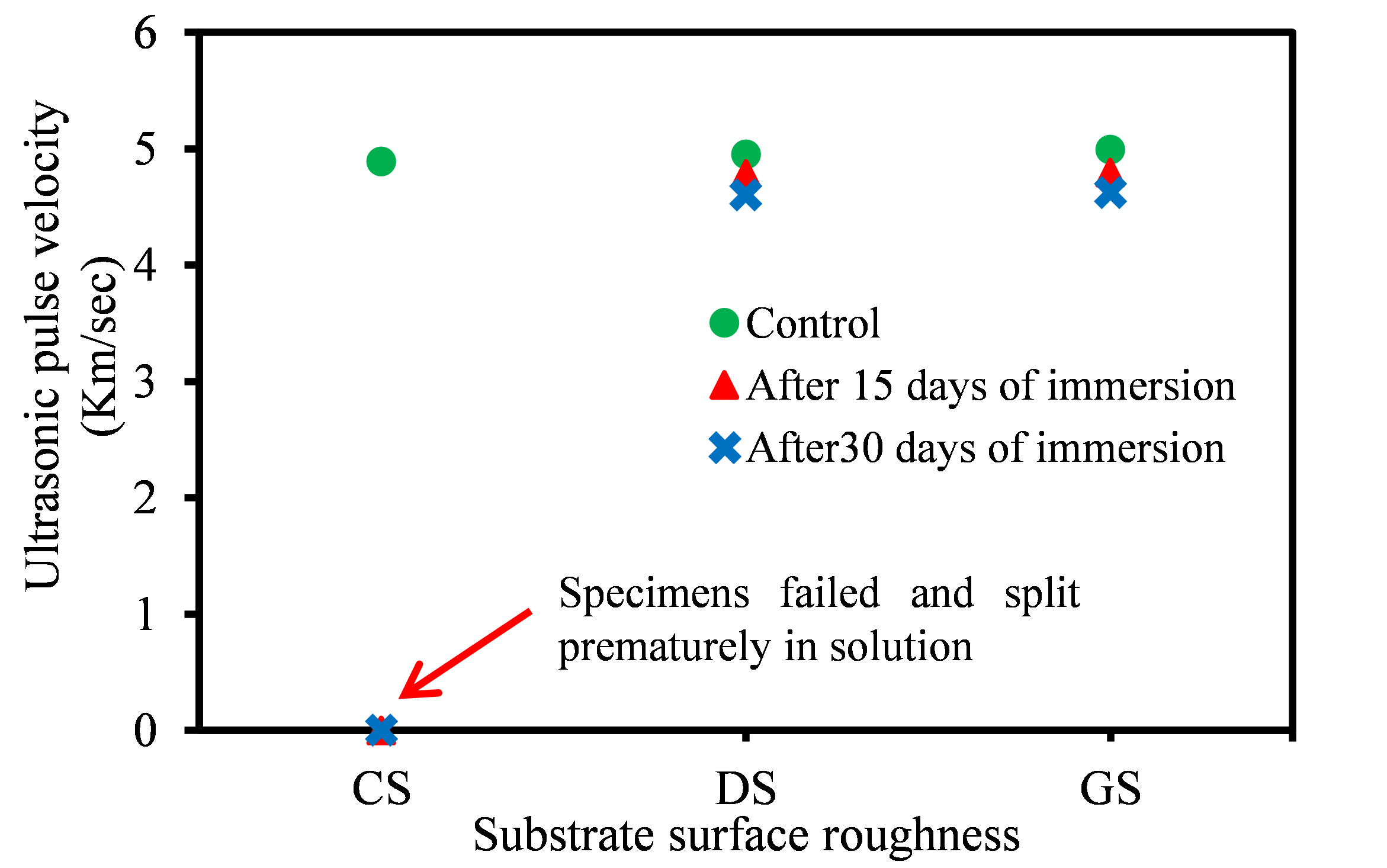

This study examines the impact of sulfuric acid on the concrete bond interface, emphasizing surface roughness variation. Three surface treatments: control surface (CS) defined as as-cast without surface preparation, drilled holes (DS), and grooved surfaces (GS). Specimens are immersed in a 5% sulfuric acid solution for 15 and 30 days. Bond performance is assessed through slant shear tests, splitting tensile tests, ultrasonic pulse velocity (UPV) measurements, mass loss evaluation, X-ray diffraction (XRD) analysis, and visual inspections of the degraded specimens. The results show that DS and GS significantly enhance shear and splitting tensile strength compared to CS. Among the treatments, GS specimens exhibited the highest shear strength and superior resistance to debonding under sulfuric acid exposure. While sulfuric acid exposure had minimal impact on UPV, roughened surfaces maintained higher UPV due to improved contact area. Visually, the GS specimens retained structural integrity after 30 days in 5% sulfuric acid, outperforming DS and CS specimens, as corroborated by XRD analysis.

References

G. Zhang and Y. Lu, “Quantifying Anisotropic Properties of Old–New Concrete Interfaces Using X-Ray Computed Tomography and Homogenization,” Infrastructures, vol. 10, no. 1, article no. 20, 2025.

A. Suzuki, et al., “Structural Damage Detection Technique of Secondary Building Components Using Piezoelectric Sensors,” Buildings, vol. 13, no. 9, article no. 2368, 2023

K. Belmokretar, K. Ayed, D. E. Kerdal, N. Leklou, and M. Mouli, “New Repair Material for Ordinary Concrete Substrates: Investigating Self-Compacting Sand Concrete and Its Interaction with Roughness of the Substrate Surface,” Journal of Materials in Civil Engineering, vol. 35, no. 9, 2023.

N. M. Altwair and S. J. Jarir, “Influence of Surface Roughness on Adhesion Between the Existing and New Plain Concretes,” Proceedings of First Conference for Engineering Sciences and Technology, vol. 2, pp. 581-591, 2018.

S. Mokhtari and M. Hassan, “Performance of Bond between Old and New Concrete Layers: The Effective Factors, Durability and Measurement Tests—A Review,” Infrastructures, vol. 9, no. 10, article no. 171, 2024.

N. N. M. Altwair, N. Y. O. Yacoub, N. A. M. Alsharif, and N. L. S. Sryh, “Influence of Surface Roughness on Durability of New-Old Concrete Interface,” Advances in Technology Innovation, vol. 9, no. 2, pp. 143–155, 2024.

D. Daneshvar, A. Behnood, and A. Robisson, “Interfacial Bond in Concrete-to-Concrete Composites: A Review,” Construction and Building Materials, vol. 359, article no. 129195, 2022.

G. Li, H. Hu, and C. Ren, “Resistance of Segmental Joints to Chloride Ions,” ACI Materials Journal, vol. 113, no. 4, 2016.

F. Li and X. Luo, “Interfacial Zone Effects of Chloride Penetration in Precast Concrete Member Joints,” Advances in Cement Research, vol. 31, no. 6, pp. 279–289, 2018.

R. Qin, H. Hao, T. Rousakis, and D. Lau, “Effect of Shrinkage Reducing Admixture on New-to-Old Concrete Interface,” Composites Part B: Engineering, vol. 167, pp. 346–355, 2018.

J. Zhao and F. Li, “Chloride Transport in Interfacial Zone of New–Old Concrete Joints of Precast Prestressed Concrete Bridges under Fatigue Load,” Journal of Materials in Civil Engineering, vol. 34, no. 10, 2022.

J. Xia, et al., “Experimental and Numerical Study on the Microstructure and Chloride Ion Transport Behavior of Concrete-to-Concrete Interface,” Construction and Building Materials, vol. 367, article no. 130317, 2023.

J. Zhang, Y. Pan, J. Li, H. Yun, and Z. Guan, “Experimental Study on Chloride Penetration of the New-to-Old Concrete Interface,” Construction and Building Materials, vol. 420, article no. 135585, 2024.

S. Gao, J. Jin, G. Hu, and L. Qi, “Experimental Investigation of the Interface Bond Properties Between SHCC and Concrete under Sulfate Attack,” Construction and Building Materials, vol. 217, pp. 651–663, 2019.

G. Li, H. Hu, and C. Ren, “Resistance of Segmental Joints to Carbonation,” ACI Materials Journal, vol. 114, no. 1, pp. 137-148, 2017.

C. Yi, et al., “Freeze-Thawing Damage Model of New-to-Old Concrete with Different Rough Interfaces,” Applied Mechanics and Materials, vol. 405–408, pp. 2707–2714, 2013.

S. A. Hadigheh, R. J. Gravina, and S. T. Smith, “Effect of Acid Attack on FRP-to-Concrete Bonded Interfaces,” Construction and Building Materials, vol. 152, pp. 285–303, 2017.

A. M. Ibrahim, M. T. Bassuoni, J. Carroll, and A. Ghazy, “Performance of Concrete Superficially Treated with Nano-Modified Coatings under Sulfuric Acid Exposures,” Journal of Building Engineering, vol. 86, article no. 108957, 2024.

Y. Sumra, S. Payam, and I. Zainah, “The pH of Cement-Based Materials: A Review,” Journal of Wuhan University of Technology-Materials Science Edition, vol. 35, no. 5, pp. 908–924, 2020.

A. M. Diab, A. E. M. A. Elmoaty, and M. R. T. Eldin, “Slant Shear Bond Strength Between Self Compacting Concrete and Old Concrete,” Construction and Building Materials, vol. 130, pp. 73–82, 2017.

B. Zhang, et al., “Interface Shear Failure Behavior Between Normal Concrete (NC) and Ultra-High Performance Concrete (UHPC),” International Journal of Concrete Structures and Materials, vol. 18, article no. 18, 2024.

V. B. dos Santos, et al., “Influence of Wetting Conditions and Concrete Strength of Both Substrate and Repair Material on the Bond Capacity of Repaired Joints,” Buildings, vol. 13, no. 3, article no. 643, 2023.

Y. Wang, X. Jiang, K. Li, and J. Qiang, “Experimental Study of Interfacial Adhesion Performance of Prefabricated UHPC-NC Diagonal Shear Groove,” Case Studies in Construction Materials, vol. 19, article no. e02343, 2023.

A. Kuncoro, et al., “Evaluation of Bonding Performance of Ultra High-Performance Concrete with Fly Ash Content as Overlay on Normal Strength Concrete,” IOP Conference Series: Earth and Environmental Science, vol. 1195, no. 1, article no. 012020, 2023.

A. Al-Shawafi et al., “Bond Behavior Between Normal Concrete and UHPC and PUC Layers Subjected to Different Loading Conditions Coupled with Fracture Analysis Technique,” Journal of Building Engineering, vol. 86, article no. 108880, 2024.

Q. Dong, Y. Li, J. Wei, and F. Lu, “Layered Structures with Rough Surfaces and Interfaces at Contact Loading,” International Journal of Mechanical Sciences, vol. 178, article no. 105611, 2020.

J. Fan, L. Wu, and B. Zhang, “Influence of Old Concrete Age, Interface Roughness and Freeze-Thawing Attack on New-to-Old Concrete Structure,” Materials, vol. 14, no. 5, article no. 1057, 2021.

P. Santos, E. Júlio, and J. Santos, “Towards the Development of an In Situ Non-Destructive Method to Control the Quality of Concrete-to-Concrete Interfaces,” Engineering Structures, vol. 32, no. 1, pp. 207–217, 2010.

J. Xiao et al., “Experimental Study on the Sulfuric Acid Corrosion Resistance of PHC Used for Pipe Pile and NSC Used in Engineering,” Buildings, vol. 13, no. 7, article no. 1596, 2023.

N. Djerfaf, Z. Nafa, and A. S. E. Belaidi, “Durability of High-Performance Concrete to an Attack by a Mixture of Sulfuric Acid and Acetic Acid,” Epitoanyag-Journal of Silicate Based and Composite Materials, vol. 75, no. 1, 2023.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Nurdeen Mohamed Altwair, Younis Omran Yacoub, Alhussin Faraj Aliwan, Waled Faraj Alnaas, Saleh Elmahdi Abdulsalam, Abdualhamid Mohamed Alsharif

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright of their article with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Oct. 01, 2015, PETI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes