Applications of Membrane Hydrocyclone Recovery of Silicon Carbide Powder

DOI:

https://doi.org/10.46604/peti.2020.4205Keywords:

separation, recovery, membrane, hydrocyclone, classificationAbstract

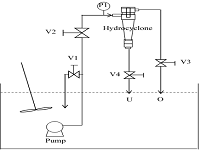

This work investigated the possibility of using membrane hydrocyclone as a separator to recover the silicon carbide powder. The weight percentage of silicon carbide powder is 62.9%. Classifying these powders by a 2.5 cm-diameter hydrocyclone that equips membrane tube in the center position, overflow and underflow are obtained. The results of the primary separation show that the overflow and underflow are about half of the proportion of solid, but silicon carbide powder content in the overflow is higher. Therefore, it is necessary to consider the recovery of silicon carbide powder contained in the overflow.

References

J. Margraf and J. Werther, “Continuous classification in a centrifugal fluidized bed apparatus,” Journal of the Taiwan Institute of Chemical Engineers, vol. 40, pp. 669-681, 2009.

K. Nageswararao, “A critical analysis of the fish hook effect in hydrocyclone classifiers,” Chemical Engineering Journal, vol. 80, pp. 251-256, 2000.

H. Yoshida, S. Taniguchi, and K. Fukui, “Effect of apex cone on particle classification performance of cyclone separator, Journal of the Taiwan Institute of Chemical Engineers, vol. 35, pp. 41-46, 2004.

D. D. Patil and T. C. Rao, “Classification evaluation of water injected hydrocyclone,” Minerals Engineering, vol. 12, pp. 1527-1532, 1999.

L. G. M. Vieira, E. A. Barbosa, J. J. R. Damasceno, and M. A. S. Barrozo, “Performance analysis and design of filtering hydrocyclones,” Brazilian Journal of Chemical Engineering, vol. 22, pp. 143-152, 2005.

A. Mainza, M. S. Powell, and B. Knopjes, “Differential classification of dense material in a three-product cyclone,” Minerals Engineering, vol. 17, pp. 573-579, 2004.

D. F. Kelsall, “A Study of the Motion of Solid Particles in a hydraulic cyclone,” Trans Instn Chem Engrs., vol. 30, pp. 87-108, 1952.

J. Bergstrom and H. Vomhoff, “Experimental hydrocyclone flow field studies,” Separation and Purification Technology, vol. 53, pp. 8-20, 2007.

J. Bergstrom, H. Vomhoff, and D. Soderberg, “Tangential velocity measurements in a conical hydrocyclone operated with a fibre suspension,” Minerals Engineering, vol. 20, pp. 407-413, 2007.

C. Y. Hsu and R. M. Wu, “Hot zone in a hydrocyclone for particles escape from overflow,” Drying Technology, vol. 26, pp. 1011-1017, 2008.

R. A. Medronho, J. Schuetze, and W. D. Deckwer, “Numerical simulation of hydrocyclones for cell separation,” Latin American Applied Research, vol. 35, pp. 1-8, 2005.

B. Wang, K. W. Chu, and A. B. Yu, “Numerical study of particle-fluid flow in a hydrocyclone,” Ind Eng Chem Res., vol. 46, pp. 4695-4705, 2007.

B. Wang and A. B. Yu, “Numerical study of the gas-liquid-solid flow in hdrocyclones with different configuration of vortex finder,” Chemical Engineering Journal, vol. 135, pp. 33-42, 2008.

L. Y. Chu, W. M. Chen, and X. Z. Lee, “Enhancement of hydrocyclone performance by controlling the inside turbulence structure,” Chemical Engineering Science, vol. 57, pp. 207-212, 2002.

B. Li, M. Huang, T. Fu, L. Pan, W. Yao, and L. Guo, “Microfiltration process by inorganic membranes for clarification of TongBi liquor,” Molecules, vol. 17, pp. 1319-1334, 2012.

M. Kim, J. H. Kim, A. S. Syed, Y. M. Kim, K. K. Choe, and C. Y. Kim, “Application of centrifugal partition chromatography for bioactivity-guided purification of antioxidant-response-element-inducing constituents from atractylodis rhizoma alba,” Molecules, vol. 23, pp. 2274-2283, 2018.

R. M. Wu, “Hydrocyclone separator,” US Patent, US 8182684 B1, May 2012.

F. G. Miller, “Dual feed hydrocyclone and method of separating aqueous slurry,” US Patent, US 4652363, March 1987.

J. A. Fallavollita, “Methods and apparatus for recovery of silicon and silicon carbide from the spent wafer-sawing slurry,” US Patent, US 2011/0059002 A1, March 2011.

S. A. Sergiienko, B. V. Pogorelov, and V. B. Daniliuk, “Silicon and silicon carbide powders recycling technology from wire-saw cutting waste in slicing process of silicon ingots,” Separation and Purification Technology, vol. 133, pp. 16-21, 2014.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright of their article with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Oct. 01, 2015, PETI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes