Experimental and Analytical Study of Silica Particles on Self-Healing Concrete

DOI:

https://doi.org/10.46604/peti.2022.9477Keywords:

GGBS, nano-silica, coconut shell, Robo sand, durability propertiesAbstract

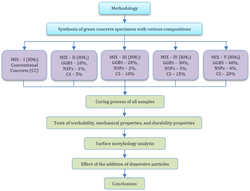

This study aims to investigate the properties of green concrete made with ground granulated blast-furnace slag (GGBS), Robo sand (RS), and coconut shell (CS). GGBS is the mineral admixture used to replace cement. Nano-silica particles (NSPs) and CS are used as coarse aggregates, and RS is the fine aggregate used to replace river sand. The workability, mechanical properties, and durability properties of green concrete are investigated and compared with those of conventional concrete (CC). Test results show that the cement replaced with 30% GGBS and 3% NSPs exhibits superior strength. The compressive and splitting tensile strengths are increased by 24.03% and 42.32% after 28 days of curing, respectively. The workability is improved by 12.22% (slump) and 13.25% (compaction factor) after 28 days of curing. The sorptivity of HM3 (3.26%) is lower than that of CC due to the uniform distribution between particles. Microstructure evolution is carried out to identify concrete mix behavior.

References

S. Ahmad, et al., “Fibre-Reinforced Self-Compacting Concrete: A Review,” IOP Conference Series: Materials Science and Engineering, vol. 377, no. 1, Article no. 012117, December 2017.

S. P. Mathew, et al., “Experimental Study of Thermal Properties of Concrete with Partial Replacement of Coarse Aggregate by Coconut Shell,” Materials Today: Proceedings, vol. 27, pp. 415-420, June 2020.

M. Palanisamy, et al., “Permeability Properties of Lightweight Self-Consolidating Concrete Made with Coconut Shell Aggregate,” Journal of Materials Research and Technology, vol. 9, no. 3, pp. 3547-57, June 2020.

E. E. Ikponmwosa, et al., “Performance of Coconut Shell Alkali-Activated Concrete: Experimental Investigation and Statistical Modelling,” Silicon, vol. 13, no. 2, pp. 335-340, March 2021.

S. U. Azunna, et al., “Characterization of Lightweight Cement Concrete with Partial Replacement of Coconut Shell Fine Aggregate,” SN Applied Science, vol. 1, no. 6, Article no. 649, May 2019.

C. A. Okeh, et al., “Behaviour of Hybrid Steel Fibre Reinforced Self Compacting Concrete Using Innovative Hooked-End Steel Fibres under Tensile Stress,” Construction and Building Materials, vol. 202, pp. 753-761, March 2019.

L. Xu, et al., “Effects of Coarse Aggregate and Steel Fibre Contents on Mechanical Properties of High Performance Concrete,” Construction and Building Materials, vol. 206, pp. 97-110, May 2019.

M. H. de Medeiros, et al., “Partial Replacement and Addition of Fly Ash in Portland Cement: Influences on Carbonation and Alkaline Reserve,” Journal of Building Pathology and Rehabilitation, vol. 2, no. 1, pp. 1-9, March 2017.

H. Sasanipour, et al., “Effect of Specimen Shape, Silica Fume, and Curing Age on Durability Properties of Self-Compacting Concrete Incorporating Coarse Recycled Concrete Aggregates,” Construction and Building Materials, vol. 228, Article no. 117054, December 2019.

S. K. Mezzal, et al., “Effect of Discarded Steel Fibers on Impact Resistance, Flexural Toughness and Fracture Energy of High-Strength Self-Compacting Concrete Exposed to Elevated Temperatures,” Fire Safety Journal, vol. 121, Article no. 103271, May 2021.

Y. Gao, et al., “Duan Preparation and Flexural Fatigue Resistance of Self-Compacting Road Concrete Incorporating Nano-Silica Particles,” Construction and Building Materials, vol. 278, Article no. 122380, April 2021.

P. Murthi, et al., “Saravanan Enhancing the Strength Properties of High-Performance Concrete Using Ternary Blended Cement: OPC, Nano-Silica, Bagasse Ash,” Silicon, vol. 21, no. 8, pp. 1949-1956, August 2019.

M. Oghabi, et al., “The Laboratory Experiment of the Effect of Quantity and Length of Plastic Fiber on Compressive Strength and Tensile Resistance of Self-Compacting Concrete,” KSCE Journal of Civil Engineering, vol. 24, no. 8, pp. 2477-2484, August 2020.

M. Amin, et al., “Effects of Nano Cotton Stalk and Palm Leaf Ashes on Ultrahigh-Performance Concrete Properties Incorporating Recycled Concrete Aggregates,” Construction and Building Materials, vol. 302, Article no. 124196, October 2021.

B. Y. Lee, et al., “Evaluation of Time to Shrinkage-Induced Crack Initiation in OPC and Slag Cement Matrices Incorporating Circulating Fluidized Bed Combustion Bottom Ash,” Construction and Building Materials, vol. 257, Article no. 119507, October 2020.

K. Nandhini, et al., “Effect of Blending Micro and Nano Silica on the Mechanical and Durability Properties of Self-Compacting Concrete,” Silicon, vol. 13, no. 3, pp. 687-695, March 2021.

L. S. Reddy, et al., “Thermal Conductivity and Strength Properties of Nanosilica and GGBS Incorporated Concrete Specimens,” Silicon, vol. 14, pp. 145-151, 2022.

I. Rahmani, et al., “A Laboratory Study on the Flexural and Shear Behavior of RC Beams Retrofitted with Steel Fiber-Reinforced Self-Compacting Concrete Jacket,” Iranian Journal of Science and Technology, vol. 45, pp. 2359-2375, 2021.

W. Chen, et al., “Dynamic Compressive Properties of High Volume Fly Ash (HVFA) Concrete with Nano Silica,” Construction and Building Materials, vol. 301, Article no. 124352, September 2021.

R. Hari, et al., “Mechanical and Durability Properties of Sisal-Nylon 6 Hybrid Fibre Reinforced High Strength SCC,” Construction and Building Materials, vol. 204, pp. 479-491, April 2019.

T. R. Praveenkumar, et al., “Microstructural Properties of Nano-Rice Husk Ash Concrete,” Nanotechnology for Environmental Engineering, vol. 4, no. 1, Article no. 9, December 2019.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright of their article with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Oct. 01, 2015, PETI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes