Efficacy of Nanocutting Fluids in Machining-an Experimental Investigation

Keywords:

nano cutting fluids, vegetable oil, CNT, MQL, surface roughnessAbstract

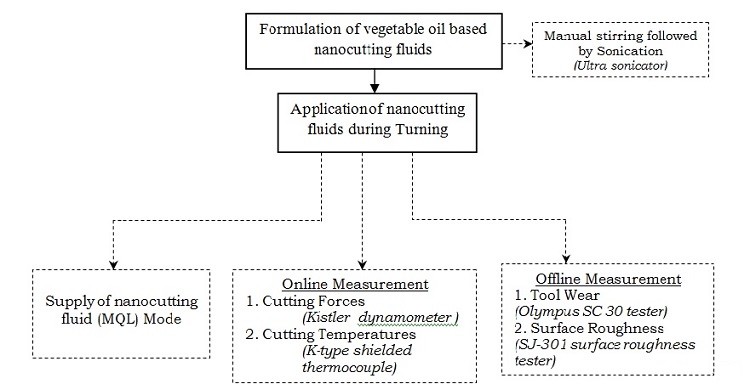

This paper presents the experimental investigations on the performance of eco-friendly vegetable oil based nanofluids in turning operation. In order to assess the quality of nano cutting fluids used during machining, cutting temperatures, cutting forces, tool wear and surface roughness under constant cutting conditions are measured. The influence of two types of nanofluids prepared from nano boric acid (NBA) and carbon nanotubes (CNT) mixed separately with coconut oil (CC), on machining performance during turning operation is examined. Comparative analysis of the results obtained is done under dry, soluble oil (SL) and lubricant environments at constant cutting conditions and 0.25% nano particle inclusions (NPI). To understand the influence of NPI experiments were conducted using CCNBA and CCCNT at varying NPI as well. Results obtained using cutting fluids prepared from vegetable oil based nanofluids are encouraging and more pronouncing by the application of CCCNT at machining zone. The extent of improvement in reduction of cutting temperatures, main cutting force, tool wear and surface roughness is tracked to be 13%, 37.5%, 44% and 40% respectively by the application of CCCNT compared to dry machining. It was found that application of CCNBA and CCCNT at 0.5% NPI is more effective in improving the machining performance.

References

E. O. Bennett and D. L. Bennett, “Occupational airways diseases in the metal working industry-part 1: respiratory infections, pneumonia, chronic bronchitis and emphysema,” Tribology International, vol. 18, no. 3, pp. 169-176, 1985.

W. J. Bartz, “Ecological and environmental aspects of cutting fluids,” Lubrication Engineering, vol. 57, no. 3, pp. 13-16, 2001.

W. Belluco and L. D. Chiffre, “Surface integrity and part accuracy in reaming and tapping stainless steel with new vegetable based cutting oils,” Tribology International, vol. 35, no. 12, pp. 865-870, 2002.

N. H. Jayadas and K. P. Nair, “Coconut oil as base oil for industrial lubricants-evaluation and modification of thermal, oxidative and low temperature properties,” Tribology International, vol. 39, no. 9, pp. 873-878, 2006.

S. Shaji and V. Radhakrishnan, “Analysis of process parameters in surface grinding with graphite as lubricant based on Taguchi method,” Journal of Materials Processing Technology, vol. 141, no. 1, pp. 51-59, 2003.

A. V. Gopal and P. V. Rao, “Performance improvement of grinding of SiC using graphite as a solid lubricant,” Materials and Manufacturing Processes, vol. 19, no. 2, pp.177-186, 2004.

N. S. K. Reddy and P. V. Rao, “Performance improvement of end milling using graphite as a solid Lubricant,” Materials and Manufacturing Processes, vol. 20, no. 4, pp. 673-686, 2005.

N. S. K. Reddy and P. V. Rao, “Experimental investigation to study effect of solid lubricants on cutting forces and surface quality in end milling,” International Journal of Machine Tools and Manufacture, vol. 46, no. 2, pp. 189-198, 2006.

S. Dilbag and P. V. Rao, “Performance improvement of hard turning with solid lubricants,” The International Journal of Advanced Manufacturing Technology, vol. 38, no. 5, pp. 529-535, 2008.

P. V. Krishna and D. N. Rao, “The influence of solid lubricant particle size on machining parameters in turning,” International Journal of Machine Tools and Manufacture, vol. 48, no. 1, pp. 107-111, 2008.

A. R. Moghadassi, S. M. Hosseini, D. Henneke, and A. Elkamel, “A model of nanofluids effective thermal conductivity based on dimensionless groups,” Journal of Thermal Analysis and Calorimetry, vol. 96, no. 1, pp. 81-84, 2001.

Y. Hwang, H. S. Park, J. K. Lee, and W. H. Jung, “Thermal conductivity and lubrication characteristics of nanofluids,” Current Applied Physics, vol. 61, no. 1, pp. e67-e71, 2001.

D. P. Kulkami, D. K. Das, and P. K. Kamburu, “Comparison of heat transfer rates of different nanofluids on the basis of the mouromtseff number,” Electronics Cooling, vol. 13, no. 3, pp. 28-32, 2007.

S. Prabhu and B. K. Vinayagam, “AFM investigation in grinding process with nanofluids using Taguchi analysis,” International Journal of Advanced Manufacturing Technology, vol. 60, no. 1, pp. 149-160, 2012.

A. Attanasio, M. Gelfi, C. Giardini, and C. Remino, “Minimum quantity lubrication in turning: effect on tool wear,” Wear, vol. 260, no. 3, pp. 333-338, 2006.

B. Shen, A. J. Shih, and S. C. Tung, “Application of nanofluids in minimum quantity lubrication grinding,” Tribology and Lubrication Technology, vol. 51, no. 6, pp. 730-737, 2008.

P. V. Krishna, R. R. Srikant, and D. N. Rao, “Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel,” International Journal of Machine Tools and Manufacture, vol. 50, no. 10, pp. 911-916, 2010.

S. Johnson and N. Saikia, “Fatty acid profile of edible oils and fats in India,” Centre for Science and Environment, pp. 1-42, 2009.

L. Horary and E. Richler, Bio-based lubricants and greases: technology and products, John Wiley and sons, 2011.

H. Thomas and W. Apple, “Proceedings: American oil chemists society,” Monograph, AOCS, p. 91, 1991.

G. Krishna Mohana Rao, R. Padmini, and S. Vamsi Krishna, “Performance evaluation of eco-friendly nano fluids in machining,” Proc. of 1st International Conference on Aeronautical and Mechanical Engineering, May 2013, pp. 221-229.

S. Shaikh, K. Lafdi, and R. Ponnappan, “Thermal conductivity improvement in carbon nanoparticle doped PAO oil: an experimental study,” Journal of Applied Physics, vol. 101, no. 6, 2007.

M. H. Cetin, B. Ozcelik, E. Kuram, and E. Demirbas, “Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by Taguchi method,” Journal of Cleaner Production, vol. 19, no. 17-18, pp. 2049-2056, 2011.

P. Sivashanmugam, “Application of nanofluids in heat transfer,” In: S. N. Kazi, ch. 14. An overview of heat transfer, INTECH Publication, 2012.

S. A. Lawal, I. A. Choudary, and Y. Nukman, “Application of vegetable oil-based metalworking fluids in machining ferrous metals- a review,” International Journal of Machine Tools and Manufacture, vol. 52, no. 1, pp. 1-12, 2012.

W. Yu and H. Xie, “A review on nanofluids: preparation, stability mechanisms and applications,” Journal of Nanomaterials, vol. 2012, no. 1, pp.1-17, 2012.

A. Erdemir, “Solid lubricants and self-lubricating films,” Modern Tribology Handbook, CRC Press, pp. 787-818, 2001.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.