Advanced Manufacture of Spiral Bevel and Hypoid Gears

Keywords:

manufacture, spiral bevel and hy-poid gears, load distribution, EHD lubrication, CNC generatorAbstract

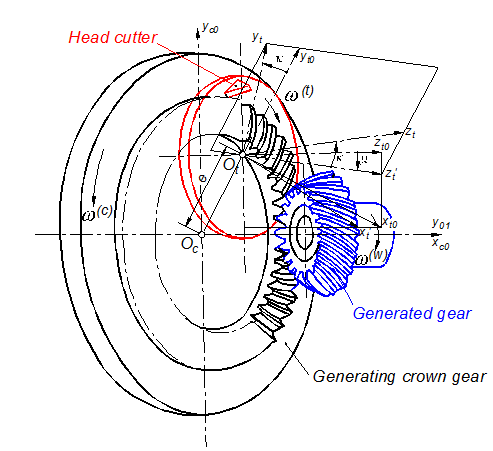

In this study, an advanced method for the manufacture of spiral bevel and hypoid gears on CNC hypoid generators is proposed. The optmal head-cutter geometry and machine tool settings are determined to introduce the optimal tooth surface modifications into the teeth of spiral bevel and hypoid gears. The aim of these tooth surface modifications is to simultaneously reduce the tooth contact pressure and the transmission errors, to maximize the EHD load carrying capacity of the oil film, and to minimize power losses in the oil film. The proposed advanced method for the manufacture of spiral bevel and hypoid gears is based on machine tool setting variation on the cradle-type generator conducted by optimal polynomial functions and on the use of a CNC hypoid generator. An algorithm is developed for the execution of motions on the CNC hypoid generator using the optimal relations on the cradle-type machine. Effectiveness of the method was demonstrated by using spiral bevel and hypoid gear examples. Significant improvements in the operating characteristics of the gear pairs are achieved.References

Y. P. Shih and Z. H. Fong, “Flank correction for spiral bevel and hypoid gears on a six-axis CNC hypoid generator,” ASME Journal of Mechanical Design, vol. 130, pp. 062604-1-8, 2008.

Q. Fan, “Tooth surface error correction for face-hobbed hypoid gears,” ASME Journal of Mechanical Design, vol. 132, pp. 011004-1-8, 2010.

Z. C. Chen and M . Wasif, “A generic and theoretical approach to programming and post-processing for hypoid gear machining on multi-axis CNC face-milling machines,” International Journal of Advanced Manufacturing and Technology, vol. 81, pp. 135-148, 2015.

W. Zhang, B. Cheng, X. Guo, M. Zhang, and Y. Xing, “A motion control method for face hobbing on CNC hypoid generator,” Mechanism and Machine Theory, vol. 92, pp. 127-143, 2015.

V. Simon, “Load distribution in hypoid gears,” ASME Journal of Mechanical Design, vol. 122, no. 4, pp. 529-535, 1998.

V. Simon, “Load distribution in spiral bevel gears,” ASME Journal of Mechanical De-sign, vol. 129, pp. 201-209, 2007.

V. Simon, “Elastohydrodynamic lubrication of hypoid gears,” Proc. of Third International Power Transmission and Gearing Conference, ASME Journal of Mechanical De-sign, vol. 103, pp. 195-203, 1981.

V. Simon, “Influence of machine tool set-ting parameters on EHD lubrication in hy-poid gears,” Mechanism and Machine Theory, vol. 44, pp. 923-937, 2009.

V. Simon, “Influence of tooth modifications on tooth contact in face-hobbed spiral bevel gears,” Mechanism and Machine Theory, vol. 46, pp. 1980-1998, 2011.

V. Simon, “Optimization of face-hobbed hypoid gears,” Mechanism and Machine Theory, vol. 77, pp. 164-181, 2014.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.