The Design and Prototype Manufacture of a Planetary Gear Reducer

Keywords:

engineering design, planetary gear reducer, prototype manufacture, train value equationAbstract

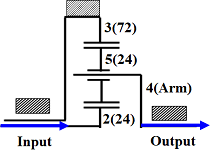

The gear reducer of the power system can be ordinary spur gear reducer, worm and worm gear reducer, or planetary gear reducer. Due to the compact size, light weight, and multi-degrees of freedom; planetary gear reducers are commonly used in various transmissions. One of its applications is used as the gear reducer for industrial purpose. The reduction ratios of 1-stage planetary gear reducers are limited to 3 ~ 10. This paper focused on the design and prototype manufacture of a 1-stage planetary gear reducer. First, according to the concept of train value equation, the planetary gear reducer with reduction ratio 4 is proposed. Based on the involute theorem, the gear data of the planetary gear reducer are obtained. Finally, based on the results of kinematic design and meshing efficiency analysis, the integrated design of the planetary gear reducer was carried out and the prototype was manufactured to verify the design theorem. The results of this paper can be used as a reference for engineers to design the gear reducers for industrial purpose.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright of their article with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Oct. 01, 2015, PETI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes