Development and Improvement of a Vacuum Fryer and a Centrifugal Deoiling Machine for Deep-Fried Split-Gill Mushroom Production

DOI:

https://doi.org/10.46604/aiti.2024.13935Keywords:

deep-fried mushrooms, vacuum frying, deoiling, production processAbstract

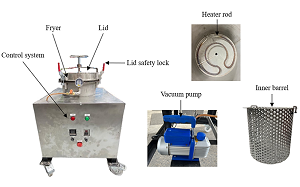

This study aims to develop a vacuum fryer and a centrifugal deoiling machine for producing deep-fried split-gill mushrooms. The vacuum fryer prototype includes a fryer, oil heater, vacuum pump, and control system, while the deoiling machine features a steel frame, external barrel, centrifugal barrel, and transmission unit. Tests are conducted by frying split-gill mushrooms at 60, 80, and 100 ℃ for 5, 10, and 15 minutes. The deoiling machine removes oil at three rotational speeds (100, 300, and 500 rpm) and deoiling times (1, 3, and 5 minutes). Results show that the ideal frying condition is 80 ℃ for 10 minutes, and the optimal deoiling is achieved in 5 minutes at 500 rpm.

References

S. Manzoor, F. A. Masoodi, R. Rashid, and T. A. Ganaie, “Quality Changes of Edible Oils During Vacuum and Atmospheric Frying of Potato Chips,” Innovative Food Science & Emerging Technologies, vol. 82, article no. 103185, 2022.

R. Asawarachan and S. Tantikun, “A Review Aricles: Vacuum Frying Technology,” Vocational Education Innovation and Research Journal, vol. 5, no. 2, pp. 124-136, 2021. (In Thai)

D. L. Abd Razak, A. Abd Ghani, M. I. M. Lazim, K. A. Khulidin, F. Shahidi, and A. Ismail, “Schizophyllum Commune (Fries) Mushroom: A Review on Its Nutritional Components, Antioxidative, and Anti-Inflammatory Properties,” Current Opinion in Food Science, vol. 56, article no. 101129, 2024.

K. Puangsuwan and S. Makon, “Development of a Smart Farm Control Application of an Evaporative Cooling Greenhouse System for Spilt Gill Mushroom Loaves,” Journal of Engineering and Innovation, vol. 15, no. 2, pp. 165-175, 2022. (In Thai)

W. Boonchouytan, J. Chatthong, and N. Pongpiriyadecha, “Development of Mixing and Pressing Processes of Split-Gill Mushroom Spawn Blocks,” Proceedings of Engineering and Technology Innovation, vol. 24, pp. 63-72, 2023.

S. A-sa, P. Kosapan, and P. Iampring, “The Oil Splashing Machine for Fried Chili to Increase the Quality of the Community Products: A Case Study of Nong Bua Daeng Community,” Journal of Science and Technology Buriram Rajabhat University (Online), vol. 5, no. 2, pp. 35-44, 2021. (In Thai)

J. Wichaphon, J. Judphol, W. Tochampa, and R. Singanusong, “Effect of Frying Conditions on Properties of Vacuum Fried Banana Bracts,” LWT, vol. 184, article no. 115022, 2023.

S. Devi, M. Zhang, R. Ju, and B. Bhandari, “Water Loss and Partitioning of the Oil Fraction of Mushroom Chips Using Ultrasound-Assisted Vacuum Frying,” Food Bioscience, vol. 38, article no. 100753, 2020.

S. Devi, M. Zhang, and C. L. Law, “Effect of Ultrasound and Microwave Assisted Vacuum Frying on Mushroom (Agaricus Bisporus) Chips Quality,” Food Bioscience, vol. 25, pp. 111-117, 2018.

P. Thongsong, S. Kamcharlearn, and S. Torsakul, “Design and Development of the Oil Shake Off Shredded Pork Prototype Machine of Ban Nong Luang Volunteer for Rural Development Women Group’s OTOP for Exporting to AEC,” Kasem Bundit Engineering Journal, vol. 8, no. 3, pp. 89-100, 2018.

W. Boonchouytan, Vacuum Frying Machine, Thailand Patent, 2303002416, August 30, 2023.

W. Boonchouytan, “Oil Extractor Centrifuge Machine,” Thailand Patent 24426, 2023.

A. Rungjumrus, “Design and Performance Analysis of a Pilot-Scale Vacuum Fryer,” M.Eng. dissertation, Department Food Engineering, King Mongkut’s Institute of Technology Thonburi, Thung Khru, Bangkok, 2005.

C. Inprasit, “Frying Under Vacuum Conditions,” B.Eng. dissertation, Department Food Engineering, Kasetsart University, Kamphaeng Saen, Nakhon Pathom, 2012.

P. Rujirapisit, “Effects of Temperature and Time on the Quality of Vacuum Fried Lotus Roots,” The Agricultural Science and Innovations Journal, vol. 40, no. 3, pp. 65-68, 2009. (In Thai)

S. Chinnasarn, “Oil Uptake in Deep-Fat Frying Process,” Burapha Science Journal, vol. 14, no. 2, pp. 138-145, 2009. (In Thai)

U. Phongrasamee, “The Oil Splashing Machine for Fried Food,” Thailand Patent 24412, 2008.

S. Yongkit, N. Yongkit, T. Kaewsripot, K. Suriyatham, and P. Junlapon, “Development of the Oil Splashing Machine for Fried Food,” Institute of Vocational Education Southern Region 1 Journal, vol. 7, no. 2, pp. 54-63, 2022. (In Thai)

U. Phongrasamee and S. Sirichai, “The Development of an Oil Splashing Machine for Fried Food of Household,” KKU Science Journal, vol. 47, no. 4, pp. 642-651, 2019. (In Thai)

C. Nampradit, “Development of Fried Kluai Hom Thong (Musa acuminata (AAA Group)) Product by Vacuum Frying,” M.Sc. dissertation, Department Agricultural Technology, Rambhai Barni Rajabhat University, Muang, Chanthaburi, 2021.

A. Jungchud, P. Wuttijumnong, K. Serikul, and C. Kusucharid, “Development of Vacuum Fried Sweet Potato,” Proceedings of the 45th Kasetsart University Annual Conference, pp. 649-655, 2007.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Worapong Boonchouytan, Nantapong Pongpiriyadecha, Nutjired Kheowsakul

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.