Optimizing Nanofluid Minimum Quantity Lubrication Machining of Inconel-800 Using Kriging Non-Dominated Sorting Genetic Algorithm II

DOI:

https://doi.org/10.46604/aiti.2024.14339Keywords:

nanofluid, machining optimization, sustainable machining, super-alloy, minimum quantity lubrication (MQL)Abstract

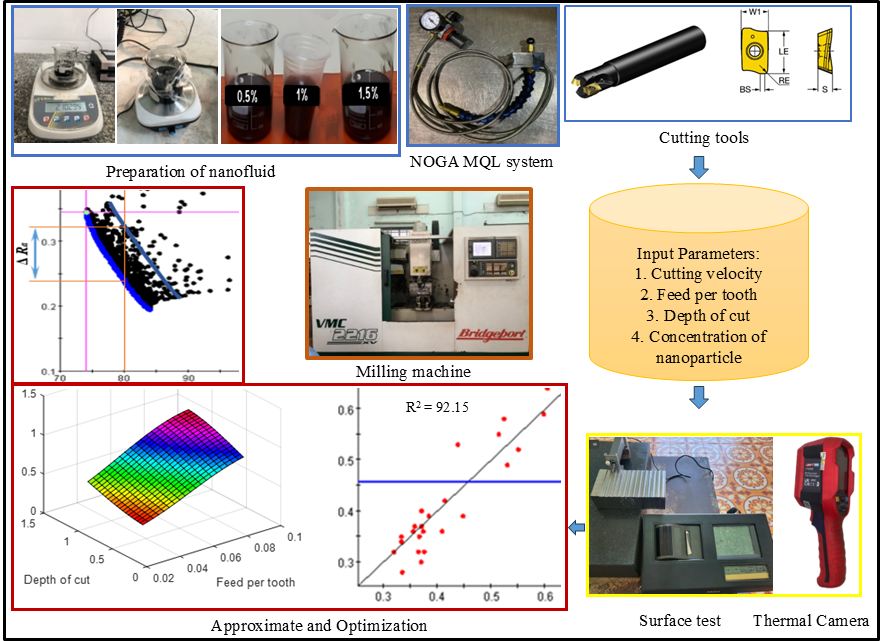

This study optimizes the machining process of Inconel-800 superalloy using nanofluid minimum quantity lubrication (MQL) with multi-wall carbon nanotubes (MWCNTs) and biodegradable coconut oil. A Taguchi design with 27 trials is used to examine the effects of varying nanoparticle concentrations and machining parameters on surface roughness and temperature. The optimized nanofluid MQL system improves surface roughness by 26.22%, reduces surface roughness peak-to-valley by 12.06%, and significantly lowers temperature, demonstrating improved quality and thermal management. A Kriging model predicts outcomes with high accuracy (R2 > 0.9), and multi-objective optimization using Kriging and the non-dominated sorting genetic algorithm II identifies an optimal balance between surface roughness and temperature. Additionally, using coconut oil as the lubricant base in the nanofluid MQL system promotes sustainable machining by reducing reliance on conventional lubricants and environmental impact. These findings validate the effectiveness of advanced optimization techniques combined with nanofluid MQL for superior sustainable machining of superalloys.

References

M. Ganesh, N. Arunkumar, N. E. Kumar, and R. Sathish, “Investigation of Surface Grinding on Inconel Under Distinct Cooling Conditions,” Materials and Manufacturing Processes, vol. 38, no. 14, pp. 1823-1836, 2023.

A. Palanisamy, N. Jeyaprakash, V. Sivabharathi, and S. Sivasankaran, “Influence of Heat Treatment on the Mechanical and Tribological Properties of Incoloy 800H Superalloy,” Archives of Civil and Mechanical Engineering, vol. 21, article no. 10, 2021

T. C. Hsiao, N. C. Vu, M. C. Tsai, X. P. Dang, and S. C. Huang, “Modeling and Optimization of Machining Parameters in Milling of Inconel-800 Super Alloy Considering Energy, Productivity, and Quality Using Nanoparticle Suspended Lubrication,” Measurement and Control, vol. 54, no. 5-6, pp. 880-894, 2021.

N. C. Vu, H. T. Nguyen, V. H. Nguyen, Q. N. Phan, N. T. Huynh, and X. P. Dang, “Experimental and Metamodel Based Optimization of Cutting Parameters for Milling Inconel-800 Superalloy under Nanofluid MQL Condition,” Mathematical Modelling of Engineering Problems, vol. 10, no. 1, pp. 189-194, 2023.

G. Gudivada and A. K. Pandey, “Recent Developments in Nickel-Based Superalloys for Gas Turbine Applications: Review,” Journal of Alloys and Compounds, vol. 963, article no. 171128, 2023

M. K. Gupta, M. Mia, C. I. Pruncu, W. Kapłonek, K. Nadolny, K. Patra, et al., “Parametric Optimization and Process Capability Analysis for Machining of Nickel-Based Superalloy,” The International Journal of Advanced Manufacturing Technology, vol. 102, pp. 3995-4009, 2019

B. Boswell, M. N. Islam, I. J. Davies, Y. R. Ginting, and A. K. Ong, “A Review Identifying the Effectiveness of Minimum Quantity Lubrication (MQL) during Conventional Machining,” The International Journal of Advanced Manufacturing Technology, vol. 92, pp. 321-340, 2017

V. S. Sharma, G. Singh, and K. Sørby, “A Review on Minimum Quantity Lubrication for Machining Processes,” Materials and Manufacturing Processes, vol. 30, no. 8, pp. 935-953, 2015.

R. Shah, K. A. Shirvani, A. Przyborowski, N. Pai, and M. Mosleh, “Role of Nanofluid Minimum Quantity Lubrication (NMQL) in Machining Application,” Lubricants, vol. 10, no. 10, article no. 266, 2022

K. Kadirgama, “A Comprehensive Review on the Application of Nanofluids in the Machining Process,” The International Journal of Advanced Manufacturing Technology, vol. 115, pp. 2669-2681, 2021

S. Chinchanikar, S. S. Kore, and P. Hujare, “A Review on Nanofluids in Minimum Quantity Lubrication Machining,” Journal of Manufacturing Processes, vol. 68, no. A, pp. 56-70, 2021.

V. K. Pasam, P. Rapeti, and S. B. Battula, “Efficacy of Nanocutting Fluids in Machining-an Experimental Investigation,” Advances in Technology Innovation, vol. 3, no. 2, pp. 78-85, 2018.

A. Hafeez, F. M. Aldosari, M. M. Helmi, H. A. Ghazwani, M. Hussien, and A. M. Hassan, “Heat Transfer Performance in a Hybrid Nanofluid (Cu-Al2O3 /Kerosene Oil) Flow Over a Shrinking Cylinder,” Case Studies in Thermal Engineering, vol. 52, article no. 103539, 2023.

I. Nouzil, M. Drummond, A. Eltaggaz, I. Deiab, and S. Pervaiz, “Experimental and Numerical Investigation of Cooling Effectiveness of Nano Minimum Quantity Lubrication,” Journal of Manufacturing Processes, vol. 108, pp. 418-429, 2023.

S. K. Yadav, S. Ghosh, and A. Sivanandam, “Surfactant Free Enhancement to Thermophysical and Tribological Performance of Bio-Degradable Lubricant with Nano-Friction Modifier for Sustainable End Milling of Incoloy 925,” Journal of Cleaner Production, vol. 428, article no. 139456, 2023.

G. I. P. Perera and T. S. Wegala, “Improving the Novel White Coconut Oil-Based Metalworking Fluid Using Nano Particles for Minimum Surface Roughness and Tool Tip Temperature,” Cleaner Materials, vol. 11, article no. 100227, 2024.

D. Y. Pimenov, L. R. R. da Silva, A. R. Machado, P. H. P. França, G. Pintaude, D. R. Unune, et al., “A Comprehensive Review of Machinability of Difficult-to-Machine Alloys with Advanced Lubricating and Cooling Techniques,” Tribology International, vol. 196, article no. 109677, 2024.

A. Ç. Şencan, Ş. Şirin, E. N. S. Saraç, B. Erdoğan, and M. R. Koçak, “Evaluation of Machining Characteristics of SiO2 Doped Vegetable Based Nanofluids with Taguchi Approach in Turning of AISI 304 Steel,” Tribology International, vol. 191, article no. 109122, 2024.

S. Hu, C. Li, Z. Zhou, B. Liu, Y. Zhang, M. Yang, et al., “Nanoparticle-Enhanced Coolants in Machining: Mechanism, Application, and Prospects,” Frontiers of Mechanical Engineering, vol. 18, article no. 53, 2023.

X. Du, J. Zheng, T. Chen, B. Guo, and X. Li, “Probing the Tribology and Drilling Performance of High Performance Cutting Fluid on Inconel 690 Superalloy by Minimum Quantity Lubrication Technology,” Alexandria Engineering Journal, vol. 88, pp. 58-67, 2024.

F. Abedrabbo, D. Soriano, A. Madariaga, R. Fernández, S. Abolghasem, and P. J. Arrazola, “Experimental Evaluation and Surface Integrity Analysis of Cryogenic Coolants Approaches in the Cylindrical Plunge Grinding,” Scientific Reports, vol. 11, article no. 20952, 2021.

N. Khanna, P. Shah, and Chetan, “Comparative Analysis of Dry, Flood, MQL and Cryogenic CO2 Techniques during the Machining of 15-5-PH SS Alloy,” Tribology International, vol. 146, article no. 106196, 2020.

M. Raja, R. Vijayan, P. Dineshkumar, and M. Venkatesan, “Review on Nanofluids Characterization, Heat Transfer Characteristics and Applications,” Renewable and Sustainable Energy Reviews, vol. 64, pp. 163-173, 2016.

A. M. Khan, M. Jamil, K. Salonitis, S. Sarfraz, W. Zhao, N. He, et al., “Multi-Objective Optimization of Energy Consumption and Surface Quality in Nanofluid SQCL Assisted Face Milling,” Energies, vol. 12, no. 4, article no. 710, 2019.

A. H. Abdelrazek, I. A. Choudhury, Y. Nukman, and S. N. Kazi, “Metal Cutting Lubricants and Cutting Tools: A Review on the Performance Improvement and Sustainability Assessment,” The International Journal of Advanced Manufacturing Technology, vol. 106, pp. 4221-4245, 2020.

I. P. Okokpujie, O. S. Ohunakin, and C. A. Bolu, “Multi-Objective Optimization of Machining Factors on Surface Roughness, Material Removal Rate and Cutting Force On End-Milling Using MWCNTS Nano-Lubricant,” Progress in Additive Manufacturing, vol. 6, pp. 155-178, 2021.

S. Sarkar and S. Datta, “Machining Performance of Inconel 718 under Dry, MQL, and Nanofluid MQL Conditions: Application of Coconut Oil (Base Fluid) and Multi-Walled Carbon Nanotubes as Additives,” Arabian Journal for Science and Engineering, vol. 46, pp. 2371-2395, 2021.

N. C. Vu, X. P. Dang, and S. C. Huang, “Multi-Objective Optimization of Hard Milling Process of AISI H13 in Terms of Productivity, Quality, and Cutting Energy under Nanofluid Minimum Quantity Lubrication Condition,” Measurement and Control, vol. 54, no. 5-6, pp. 820-834, 2021.

T. T. Nguyen, X. B. Le, “Optimization of Roller Burnishing Process using Kriging Model to Improve Surface Properties,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol. 233, no. 12, pp. 2264-2282, 2019.

G. T. Bui, T. V. Do, Q. M. Nguyen, M. H. P. Thi, and M. H. Vu, “Multi-Objective Optimization For Balancing Surface Roughness and Material Removal Rate in Milling Hardened SKD11 Alloy Steel with SiO2 Nanofluid MQL,” EUREKA: Physics and Engineering, no. 2, pp. 157-169, 2024.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Ngoc-Chien Vu, Huu-That Nguyen, Xuan- Phuong Dang

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.