Enhancement of Properties of Fly Ash Geopolymer Paste with Low NaOH Concentrations Using a Pressing Approach

DOI:

https://doi.org/10.46604/aiti.2024.14516Keywords:

compressive strength, geopolymers, low molar, pressing approachAbstract

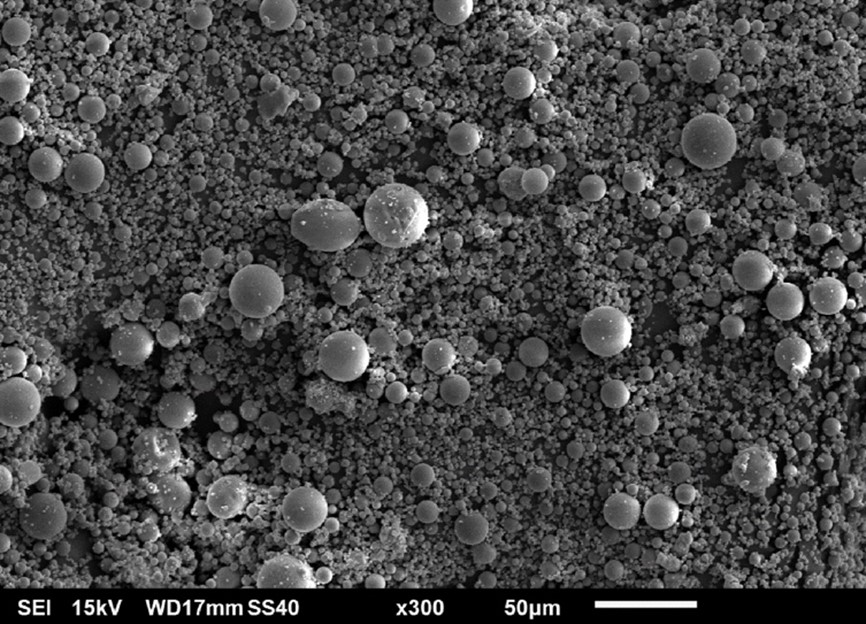

Geopolymers are widely recognized as an eco-friendly alternative material. However, the impact of pressing stresses and low NaOH concentrations on their properties remains underexplored. This research aims to investigate the effects of pressing stresses on unit weight, porosity, water absorption, and compressive strength of high-calcium fly ash geopolymer paste with low NaOH concentrations. The low NaOH concentrations of 0.5, 1.0, and 2.0 M, pressing stresses of 10, 20, and 30 MPa, and liquid-to-binder ratios of 0.10, 0.12, 0.14, 0.16, 0.18, and 0.20 by weight are used. The specimens of geopolymer paste are oven-dried at 60°C for 24 hours before evaluation. The testing results show that the compressive strength of casted geopolymer paste is between 2 to 15 MPa, with higher compressive strength associated with lower porosity. The water absorption rate is between 11% and 21% by weight, which has a higher water absorption rate as the porosity increases.

References

H. Zeng, S. Qu, Y. Tian, Y. Hu, and Y. Li, “Recent Progress on Graphene Oxide for Next-Generation Concrete: Characterizations, Applications and Challenges,” Journal of Building Engineering, vol. 69, article no. 106192, 2023.

G. Mishra, P. A. Danoglidis, S. P. Shah, and M. S. Konsta Gdoutos, “Carbon Capture and Storage Potential of Biochar-Enriched Cementitious Systems,” Cement and Concrete Composites, vol. 140, article no. 105078, 2023.

N. Toobpeng, P. Thavorniti, and S. Jiemsirilers, “Effect of Additives on the Setting Time and Compressive Strength of Activated High-Calcium Fly Ash-Based Geopolymers,” Construction and Building Materials, vol. 417, article no. 135035, 2024.

L. Cao, Y. Zuo, S. Liang, Y. Sun, Y. Ke, J. Yang, et al., “Geopolymerization of MSWI Fly Ash and Coal Fly Ash for Efficient Solidification of Heavy Metals: Insights into Stabilization Mechanisms and Long-Term Leaching Behavior,” Construction and Building Materials, vol. 411, article no. 134359, 2024.

T. Tesanasin, C. Suksiripattanapong, B. Van Duc, W. Tabyang, C. Phetchuay, T. Phoo-ngernkham, et al., “Engineering Properties of Marginal Lateritic Soil Stabilized with One-part High Calcium Fly Ash Geopolymer as Pavement Materials,” Case Studies in Construction Materials, vol. 17, article no. e01328, 2022.

T. Tesanasin, C. Suksiripattanapong, T. Kuasakul, T. Thongkhwan, W. Tabyang, J. Thumrongvut, et al., “Comparison between Cement-rice Husk Ash and Cement-rice Husk Ash One-part Geopolymer for Stabilized Soft Clay as Deep Mixing Material,” Transportation Infrastructure Geotechnology, vol. 11, no. 4, pp. 1760-1776, 2024.

W. Tabyang, C. Suksiripattanapong, C. Phetchuay, C. Laksanakit, and N. Chusilp, “Evaluation of Municipal Solid Waste Incineration Fly Ash Based Geopolymer for Stabilised Recycled Concrete Aggregate as Road Material,” Road Materials and Pavement Design, vol. 23, no. 9, pp. 2178-2189, 2022.

W. Tabyang, T. Kuasakul, P. Sookmanee, C. Laksanakit, N. Chusilp, Y. Bamrungphon, et al., “Use of a Rubber Wood Fly Ash-based Geopolymer for Stabilizing Marginal Lateritic Soil as Green Subbase Materials,” Clean Technologies Environmental Policy, vol. 26, no. 6, pp. 2059-2073, 2024.

S. B. Singh, P. R. Maiti, and S. Mohanty. “Development of filler-free and ambient-cured fly ash Based geopolymer brick utilizing low molar concentration of activating solution,” Case Studies in Construction Materials, vol. 21, article no. e04032, 2024.

Z. Li, M. Gao, Z. Lei, L. Tong, J. Sun, Y. Wang, et al., “Ternary Cementless Composite Based on Red Mud, Ultra-Fine Fly Ash, and GGBS: Synergistic Utilization and Geopolymerization Mechanism,” Case Studies in Construction Materials, vol. 19, article no. e02410, 2023.

N. A. Vahab, R. S. Deepa, and M. Soman, “A Review on Microstructural, Mechanical, and Durability Characteristics of Raw Kaolin Clay-Based Geopolymers,” AIP Conference Proceedings. vol. 3010, no.1, article no. 020006, 2024.

P. Yoosuk, C. Suksiripattanapong, P. Sukontasukkul, and P. Chindaprasirt, “Properties of Polypropylene Fiber Reinforced Cellular Lightweight High Calcium Fly Ash Geopolymer Mortar,” Case Studies in Construction Materials, vol. 15, article no. e00730, 2021.

A. Kul, B. F. Ozel, E. Ozcelikci, M. F. Gunal, H. Ulugol, G. Yildirim, et al., “Characterization and Life Cycle Assessment of Geopolymer Mortars with Masonry Units and Recycled Concrete Aggregates Assorted from Construction and Demolition Waste,” Journal of Building Engineering, vol. 78, article no. 107546, 2023.

A. Amri, A. Amartya, Y. Ilham, S. Sutikno, S. Reni Yenti, B. Ibrahim, D. Heltina, et al., “The Addition of Low-Cost Few Layers Graphene (FLG) to Improve Flexural Strength of Coal Fly Ash Based-Geopolymer,” Journal of Materials Research and Technology, vol. 24, pp. 8849-8855, 2023.

W. Prachasaree, S. Limkatanyu, A. Hawa, P. Sukontasukkul, and P. Chindaprasirt, “Manuscript Title: Development of Strength Prediction Models for Fly Ash Based Geopolymer Concrete,” Journal of Building Engineering, vol. 32, article no. 101704, 2020.

M. Łach, A. Bąk, K. Pławecka, and M. Hebdowska-Krupa, “Possibility of Using a Geopolymer Containing Phase Change Materials as a Sprayed Insulating Coating - Preliminary Results,” Emerging Science Innovation, vol. 2, 2024, pp. 01-08, 2024.

W. T. Lin, K. L. Lin, K. Korniejenko, and L. Fiala, “Comparative Analysis Between Fly Ash Geopolymer and Reactive Ultra-Fine Fly Ash Geopolymer,” International Journal of Engineering and Technology Innovation, vol. 11, no. 3, pp. 161-170, 2021.

M. Łach, J. Mikuła, W. T. Lin, P. Bazan, B. Figiela, and K. Korniejenko, “Development and Characterization of Thermal Insulation Geopolymer Foams Based on Fly Ash,” Proceedings of Engineering and Technology Innovation, vol. 16, pp. 23-29, 2020.

P. Nuaklong, P. Jongvivatsakul, T. Pothisiri, V. Sata, and P. Chindaprasirt, “Influence of Rice Husk Ash on Mechanical Properties and Fire Resistance of Recycled Aggregate High-Calcium Fly Ash Geopolymer Concrete,” Journal of Cleaner Production, vol. 252, article no. 119797, 2020.

P. Chindaprasirt, T. Chareerat, and V. Sirivivatnanon, “Workability and Strength of Coarse High Calcium Fly Ash Geopolymer,” Cement and Concrete Composites, vol. 29, no. 3, pp. 224-229, 2007.

Q. Guo, M. Wei, H. Wu, and Y. Gu, “Strength and Micro-Mechanism of MK-Blended Alkaline Cement Treated High Plasticity Clay,” Construction and Building Materials, vol. 236, article no. 117567, 2020.

L. Zheng, W. Wang, and Y. Shi, “The Effects of Alkaline Dosage and Si/Al Ratio on the Immobilization of Heavy Metals in Municipal Solid Waste Incineration Fly Ash-Based Geopolymer,” Chemosphere, vol. 79, no. 6, pp. 665-671, 2010.

H. Takeda, S. Hashimoto, H. Matsui, S. Honda, and Y. Iwamoto, “Rapid Fabrication of Highly Dense Geopolymers Using a Warm Press Method and Their Ability to Absorb Neutron Irradiation,” Construction and Building Materials, vol. 50, pp. 82-86, 2014.

K. Ramujee and M. PothaRaju, “Mechanical Properties of Geopolymer Concrete Composites,” Materials Today: Proceedings, vol. 4, no. 2, Part A, pp. 2937-2945, 2017.

H. L. Dinh, J. Liu, J. H. Doh, and D. E. L. Ong, “Influence of Si/Al Molar Ratio and Ca Content on the Performance of Fly Ash-Based Geopolymer Incorporating Waste Glass and GGBFS,” Construction and Building Materials, vol. 411, article no. 134741, 2024.

American Society for Testing and Materials, ASTM standard C 618, 2003.

S. W. Ong, C. Y. Heah, Y. M. Liew, M. M. A. B. Abdullah, L. N. Ho, P. Pakawanit, et al., “Green Development of Fly Ash Geopolymer via Casting and Pressing Approaches: Strength, Morphology, Efflorescence and Ecological Properties,” Construction and Building Materials, vol. 398, article no. 132446, 2023.

M. Alshaaer, “Two-Phase Geopolymerization of Kaolinite-Based Geopolymers,” Applied Clay Science, vol. 86, pp. 162-168, 2013.

S. Prasanphan, A. Wannagon, T. Kobayashi, and S. Jiemsirilers, “Reaction Mechanisms of Calcined Kaolin Processing Waste-Based Geopolymers in the Presence of Low Alkali Activator Solution,” Construction and Building Materials, vol. 221, pp. 409-420, 2019.

P. Yoosuk, C. Suksiripattanapong, G. Hiroki, T. Phoo-ngernkham, J. Thumrongvut, P. Sukontasukkul, et al., “Performance of Polypropylene Fiber-reinforced Cellular Lightweight Fly Ash Geopolymer Mortar under Wet and Dry Cycles,” Case Studies in Construction Materials, vol. 20, article no. e03233, 2024.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Khamphee Jitchaiyaphum, Cherdsak Suksiripattanapong

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.