Finite Element Analysis of Ti-6Al-4V Lattice Cubic Scaffolds for Mandibular Bone Implant Applications

DOI:

https://doi.org/10.46604/aiti.2024.14542Keywords:

Ti-6Al-4V material strength, lattice beam type cubic scaffold, mandibular bone implant, additive manufacturing, compressive strengthAbstract

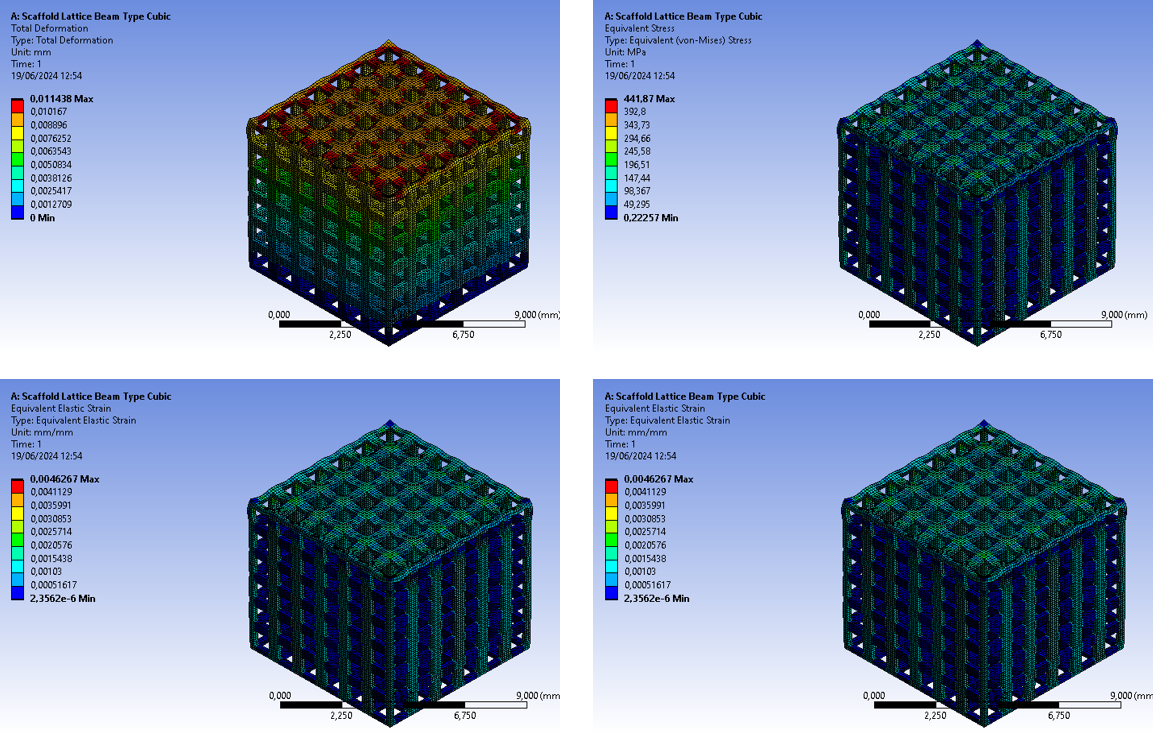

This study evaluates the compressive strength of a cubic lattice scaffold made from Titanium alloy (Ti-6Al-4V) for mandibular bone implants. Scaffold designs with pore sizes ranging from 800 µm to 1000 µm were analyzed using finite element analysis under compressive forces of up to 800 N. Pore sizes of 800 µm and 850 µm achieved a safety factor greater than 1.4, indicating their suitability for both dynamic and static loading. Planned production with bound metal deposition, maintaining a density below 35%, emphasizes material efficiency and cost-effectiveness. Results indicate that 800 µm and 850 µm pore sizes offer optimal strength and safety, suggesting effective mandibular implant integration. Further research on cyclic load testing and osseointegration is recommended.

References

"BRIN Kembangkan Riset Material untuk Implan Tulang," https://www.brin.go.id/news/110583/brin-kembangkan-riset-material-untuk-implan-tulang, accessed in 2024.

C. Shuai, et al., "An nMgO Containing Scaffold: Antibacterial Activity, Degradation Properties and Cell Responses," International Journal of Bioprinting, vol. 4, no. 1, article no. 120, 2018.

J. He, F. Xu, R. Dong, B. Guo, and D. Li, "Electrohydrodynamic 3D Printing of Microscale Poly (ε-Caprolactone) Scaffolds with Multi-Walled Carbon Nanotubes," Biofabrication, vol. 9, no. 1, article no. 015007, 2017.

R. Winarso, R. Ismail, P. W. Anggoro, J. Jamari, and A. P. Bayuseno, "Numerical Study on Mechanical Properties of Cubic Porous Bone Scaffold: Effect of Unit Cell Type," AIP Conference Proceedings, vol. 3074, no. 1, article no. 020001, 2024.

M. Guvendiren, J. Molde, R. M. D. Soares, and J. Kohn, "Designing Biomaterials for 3D Printing," ACS Biomaterials Science & Engineering, vol. 2, no. 10, pp. 1679-1693, 2016.

R. Winarso, R. Ismail, P. W. Anggoro, J. Jamari, and A. P. Bayuseno, "A Scoping Review of the Additive Manufacturing of Mandibular Implants," Frontiers in Mechanical Engineering, vol. 9, article no. 1079887, 2023.

S. Dhiman, et al., "Cubic Lattice Structures of Ti6Al4V under Compressive Loading: Towards Assessing the Performance for Hard Tissue Implants Alternative," Materials, vol. 14, no. 14, article no. 3866, 2021.

R. Winarso, R. Ismail, P. W. Anggoro, J. Jamari, and A. P. Bayuseno, "Finite Element Analysis of Irregular Porous Scaffold for Bone Tissue Engineering," ARPN Journal of Engineering and Applied Sciences, vol. 18, no. 6, pp. 569-580, 2023.

R. Winarso, P. W. Anggoro, R. Ismail, J. Jamari, and A. P. Bayuseno, "Application of Fused Deposition Modeling (FDM) on Bone Scaffold Manufacturing Process: A Review," Heliyon, vol. 8, no. 11, article no. e11701, 2022.

C. Ghayor, T. H. Chen, I. Bhattacharya, M. Ozcan, and F. E. Weber, "Microporosities in 3D-Printed Tricalcium-Phosphate-Based Bone Substitutes Enhance Osteoconduction and Affect Osteoclastic Resorption," International Journal of Molecular Sciences, vol. 21, no. 23, article no. 9270, 2020.

C. Ghayor and F. E. Weber, "Osteoconductive Microarchitecture of Bone Substitutes for Bone Regeneration Revisited," Frontiers in Physiology, vol. 9, article no. 960, 2018.

S. Rasheed, W. Lughmani, M. A. Obeidi, D. Brabazon, and I. Ahad, "Additive Manufacturing of Bone Scaffolds Using PolyJet and Stereolithography Techniques," Applied Sciences, vol. 11, no. 16, article no. 7336, 2021.

A. Dutta, K. Mukherjee, S. Dhara, and S. Gupta, "Design of Porous Titanium Scaffold for Complete Mandibular Reconstruction: The Influence of Pore Architecture Parameters," Computers in Biology and Medicine, vol. 108, pp. 31-41, 2019.

W. M. Peng, et al., "Biomechanical and Mechanostat Analysis of a Titanium Layered Porous Implant for Mandibular Reconstruction: The Effect of the Topology Optimization Design," Materials Science and Engineering: C, vol. 124, article no. 112056, 2021.

I. Bianchi, V. Di Pompeo, T. Mancia, M. Pieralisi, and A. Vita, "Environmental Impacts Assessment of Bound Metal Deposition 3D Printing Process for Stainless Steel," Procedia CIRP, vol. 105, pp. 386-391, 2022.

A. Watson, J. Belding, and B. D. Ellis, "Characterization of 17-4 PH Processed via Bound Metal Deposition (BMD)," Proceedings of TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings, Springer, Cham, pp. 205-216, 2020.

D. G. Luchinsky, et al., "Multi-Scale Modelling of the Bound Metal Deposition Manufacturing of Ti6Al4V," Thermo, vol. 2, no. 3, pp. 116-148, 2022.

V. Di Pompeo, et al., "Microstructure and Defect Analysis of 17-4PH Stainless Steel Fabricated by the Bound Metal Deposition Additive Manufacturing Technology," Crystals, vol. 13, no. 9, article no. 1312, 2023.

F. Bjørheim and I. M. La Torraca Lopez, "Tension Testing of Additively Manufactured Specimens of 17-4 PH Processed by Bound Metal Deposition," IOP Conference Series: Materials Science and Engineering, vol. 1201, no. 1, article no. 012037, 2021.

S. N. Huang, et al., "Biomechanical Assessment of Design Parameters on a Self-Developed 3D-Printed Titanium-Alloy Reconstruction/Prosthetic Implant for Mandibular Segmental Osteotomy Defect," Metals, vol. 9, no. 5, article no. 597, 2019.

C. H. Li, C. H. Wu, and C. L. Lin, "Design of a Patient-Specific Mandible Reconstruction Implant with Dental Prosthesis for Metal 3D Printing Using Integrated Weighted Topology Optimization and Finite Element Analysis," Journal of the Mechanical Behavior of Biomedical Materials, vol. 105, article no. 103700, 2020.

C. L. Lin, Y. T. Wang, C. M. Chang, C. H. Wu, and W. H. Tsai, "Design Criteria for Patient-Specific Mandibular Continuity Defect Reconstructed Implant with Lightweight Structure Using Weighted Topology Optimization and Validated with Biomechanical Fatigue Testing," International Journal of Bioprinting, vol. 8, no. 1, article no. 437, 2021.

Z. Chen, et al., "Influence of the Pore Size and Porosity of Selective Laser Melted Ti6Al4V ELI Porous Scaffold on Cell Proliferation, Osteogenesis and Bone Ingrowth," Materials Science and Engineering. C, Materials for Biological Applications, vol. 106, article no. 110289, 2020.

R. Alkentar, F. Mate, and T. Mankovits, "Investigation of the Performance of Ti6Al4V Lattice Structures Designed for Biomedical Implants Using the Finite Element Method," Materials (Basel, Switzerland), vol. 15, no.18, article no. 6335, 2022.

X. Xu, D. Luo, C. Guo, and Q. Rong, "A Custom-Made Temporomandibular Joint Prosthesis for Fabrication by Selective Laser Melting: Finite Element Analysis," Medical Engineering & Physics, vol. 46, pp. 1-11, 2017.

C. Wang, et al., "Effect of Pore Size on the Physicochemical Properties and Osteogenesis of Ti6Al4V Porous Scaffolds with Bionic Structure," ACS Omega, vol. 5, no. 44, pp. 28684-28692, 2020.

Y. R. K. Cham, S. S. Hoshi, and S. V. Nimje, "Innovation in the Impact Structure Design of a Four Wheel Automobile," International Research Journal of Engineering and Technology, vol. 5, no. 9, pp. 84-87, 2018.

M. Ahmad, K. A. Ismail, and F. Mat, "Convergence of Finite Element Model for Crushing of a Conical Thin-Walled Tube," Procedia Engineering, vol. 53, pp. 586-593, 2013.

Y. H. Shash, M. T. El-Wakad, M. A. A. Eldosoky, and M. M. Dohiem, "Evaluation of Stress and Strain on Mandible Caused Using “All-on-Four” System from PEEK in Hybrid Prosthesis: Finite-Element Analysis," Odontology, vol. 111, no. 3, pp. 618-629, 2023.

B. Liu, et al., "The Optimization of Ti Gradient Porous Structure Involves the Finite Element Simulation Analysis," Frontiers in Materials, vol. 8, article no. 642135, 2021.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yasya Khalif Perdana Saleh, Rifky Ismail, Jamari Jamari, I Nyoman Jujur, Suryadi Suryadi, Rochmad Winarso, Tepi Anggara

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.