Development of a Cost-effective Design of a P-V Ventilated Greenhouse Solar Dryer for Commercial Preservation of Tomatoes in a Rural Setting

Keywords:

commercial preservation, thermo-physical properties, embodiment of design, thermal energy storage systemAbstract

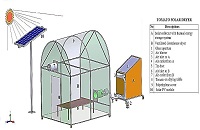

Commercial preservation of agro-produce by solar drying entails using large-scale dryer units that are generally not affordable by potential users in a rural setting. The objective of this study was to design a photo-voltaic greenhouse solar drying unit with air convection powered by a photovoltaic system as part of a research study to develop a cost-effective commercial solar dryer for the preservation of tomatoes in a rural setting. The design methodology involved. First, the determination of thermophysical properties of local tomatoes and predicting its drying model. Second, determination of design parameters; design equations, design conditions and assumptions, and psychrometric analysis. Third, application of the design parameters under the climatic conditions of Botswana to produce the embodiment of design with the drawings and specifications for a solar hot air dryer unit of 2000 kg batch-load of wet tomatoes. This drying unit is integrated into a solar collector with a cost-friendly thermal energy storage system to store solar energy during the day for use after sunset for better performance.

References

W. H. Organization, “The state of food security and nutrition in the world 2018: building climate resilience for food security and nutrition,” Food & Agriculture Organization of the United Nations, 2018.

M. Güne, B. Blywis, F. Juraschek, and P. Schmidt, “Concept and design of the hybrid distributed embedded systems testbed,” Freie Universität Berlin, Technology Rep., 2008.

C. Gordon and S. Thorne, “Determination of the thermal diffusivity of foods from temperature measurements during cooling,” Journal of Food Engineering, vol. 11, no. 2, pp. 133-145, 1990.

C. Cheapok and P. Pornnareay, “Introducing solar drying in a developing country: the case of Cambodia,” Proceedings of World Renewable Energy Congress (WREC), pp. 2198-2201, 2000.

A. Esper, K. Lutz, and W. Mühlbauer, “Development and testing of plastic film solar air heaters,” Solar & Wind Technology, vol. 6, no. 3, pp. 189-195, 1989.

H. C. Kaymak, I. Ozturk, F. Kalkan, M. Kara, and S. Ercisli, “Color and physical properties of two common tomatoes (lycopersicon esculentum Mill.) cultivars,” Journal of Food Agriculture and Environment, vol. 8, no. 2, pp. 44-46, April 2010.

A. Fudholi, K. Sopian, M. H. Ruslan, M. Alghoul, and M. Sulaiman, “Review of solar dryers for agricultural and marine products,” Renewable and Sustainable Energy Reviews, vol. 14, no. 1, pp. 1-30, January 2010.

W. Weiss and J. Buchinger, “Solar Drying,” AEE INTEC Publication, A-8200 Gleisdorf, Feldgasse, vol. 19, 2012.

S. Lahsasni, M. Kouhila, M. Mahrouz, L. Mohamed, and B. Agorram, “Characteristic drying curve and mathematical modeling of thin‐layer solar drying of prickly pear cladode (opuntia ficus indica),” Journal of Food Process Engineering, vol. 27, no. 2, pp. 103-117, June 2004.

B. Bala, M. Mondol, B. Biswas, B. D. Chowdury, and S. Janjai, “Solar drying of pineapple using solar tunnel drier,” Renewable Energy, vol. 28, no. 2, pp. 183-190, February 2003.

R. Goyal and G. Tiwari, “Parametric study of a reverse flat plate absorber cabinet dryer: a new concept,” Solar Energy, vol. 60, no. 1, pp. 41-48, January 1997.

M. Hossain, K. Gottschalk, and B. Amer, “Mathematical modelling for drying of tomato in hybrid dryer,” Arabian Journal for Science and Engineering, vol. 35, no. 2, pp. 239, October 2010.

M. G. Green and D. Schwarz, “Solar dryer plans,” 2014.

S. Janjai, “A greenhouse type solar dryer for small-scale dried food industries: development and dissemination,” International Journal of Energy and Environment, vol. 3, no. 3, pp. 383-398, January 2012.

C. Hii, C. Law, and M. Cloke, “Modeling using a new thin layer drying model and product quality of cocoa,” Journal of Food Engineering, vol. 90, no. 2, pp. 191-198, January 2009.

M. Hawlader, M. Uddin, J. Ho, and A. Teng, “Drying characteristics of tomatoes,” Journal of Food Engineering, vol. 14, no. 4, pp. 259-268, 1991.

S. Sengar and S. Kothari, “Thermal modeling and performance evaluation of arch shape greenhouse for nursery raising,” African Journal of Mathematics and Computer Science Research, vol. 1, pp. 1-9, 2008.

H. Atalay, M. T. Çoban, and O. Kıncay, “Modeling of the drying process of apple slices: application with a solar dryer and the thermal energy storage system,” Energy, vol. 134, pp. 382-391, September 2017.

O. Badaoui, S. Hanini, A. Djebli, B. Haddad, and A. Benhamou, “Experimental and modelling study of tomato pomace waste drying in a new solar greenhouse: Evaluation of new drying models,” Renewable energy, vol. 133, pp. 144-155, April 2019.

N. I. Román‐Roldán, A. López‐Ortiz, J. F. Ituna‐Yudonago, O. García‐Valladares, and I. Pilatowsky‐Figueroa, “Computational fluid dynamics analysis of heat transfer in a greenhouse solar dryer “chapel‐type” coupled to an air solar heating system,” Energy Science & Engineering, 2019.

Baliyan, S. P. M., Shesha Rao. (2013). Evaluation of Tomato Varieties for Pest and Disease Adaptation and Productivity in Botswana. International Journal of Agricultural and Food Research.

Purkayastha, M. D.,Nath, A.,Deka, B. C. and Mahanta, C. L. (2013). Thin layer drying of tomato slices. Journal of Food science and Technology, vol. 50, no. 4, pp. 642-653.

M. G. S. Green, “Solar drying technology for food preservation,” GTZ-GATE, January 2011D. Brooker, “Mathematical model of the psychrometric chart,” Transactions of the ASAE, vol. 10, pp. 558-560, 1967.

B. A. Berichte, “Experimental studies and mathematical modelling of solar drying system for production of high quality dried tomato,” pp. 1-173, 2007.D. Jain and P. B. Pathare, “Study the drying kinetics of open sun drying of fish,” Journal of Food Engineering, vol. 78, no. 4, pp. 1315-1319, February 2007.

S. Youcef-Ali, H. Messaoudi, J. Desmons, A. Abene, and M. Le Ray, “Determination of the average coefficient of internal moisture transfer during the drying of a thin bed of potato slices,” Journal of Food Engineering, vol. 48, no. 2, pp. 95-101, May 2001.

E. Akoy, M. Ismail, A. Ahmed, and W. Luecke, “Design and construction of a solar dryer for mango slices,” Proceedings of International Research on Food Security, Natural Resource Management and Rural Development-Tropentag. University of Bonn, Germany.

V. Puri and R. Anantheswaran, “The finite-element method in food processing: a review. Journal of Food engineering,” vol. 19, no. 3, pp. 247-274.

C. Hii, C. Law, and M. Cloke, “Modeling using a new thin layer drying model and product quality of cocoa. Journal of Food engineering,” vol. 90, no. 2, pp. 191-198.

J. Hernandez, G. Pavon, and M. Garcıa, “Analytical solution of mass transfer equation considering shrinkage for modeling food-drying kinetics,” Journal of Food Engineering, vol. 45, no. 1, pp. 1-10, July 2000.

D. Jain and P. B. Pathare, “Study the drying kinetics of open sun drying of fish,” Journal of Food Engineering, vol. 78, no. 4, pp. 1315-1319, February 2007.

D. Wray and H. S. Ramaswamy, “Novel concepts in microwave drying of foods. Drying Technology,” vol. 33, no. 7, pp. 769-783.

M. Sodha, N. Bansal, A. Kumar, P. Bansal, and M. Malik, “Solar crop drying,” CPR press., Boca Raton, Florida, USA, 1987.

D. Brooker, “Mathematical model of the psychrometric chart,” Transactions of the ASAE, vol. 10, pp. 558-560, 1967.

P. Greidanus and M. A. Verhoeven, “Product data of tomatoes,” Sprenger Instituut, Wageningen 0169-3638, 1986.

G. Giovanelli, B. Zanoni, V. Lavelli, and R. Nani, “Water sorption, drying and antioxidant properties of dried tomato products,” Journal of Food Engineering, vol. 52, no. 2, pp. 135-141, April 2002.

B. Amer, M. Hossain, and K. Gottschalk, “Design and performance evaluation of a new hybrid solar dryer for banana,” Energy conversion and management, vol. 51, pp. 813-820, 2010.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.