The Design of Mold Clamping Mechanisms with Two Dead-Position Configurations

DOI:

https://doi.org/10.46604/aiti.2020.4164Keywords:

blow-molding machine, conceptual design, creative design, dead-position configuration, mold clamping mechanismAbstract

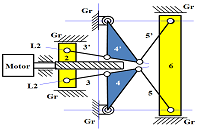

Blow-molding machines are divided into two types: (1) rotary type blow-molding machine, and (2) linear type blow-molding machine. Good kinematic characteristics of mold clamping mechanism is the goal pursued by manufacturers of blow-molding machine. Traditionally, the mold clamping mechanism has only one dead-position configuration for the mold in the closed position. When the mold is in the open position, the mold clamping mechanism does not have dead-position configuration. This study focuses on the design of mold clamping mechanisms with two dead-position configurations when the mold is in open and closed positions. Firstly, with reference to the existing patents, based on the Yan's creative design methodology, four design concepts of mold clamping mechanisms are synthesized. Then, according to the studies on kinematics of mechanisms, three mold clamping mechanisms with two dead-position configurations are also synthesized. The results of this paper will enhance the research and development (R&D) capability of the mold clamping mechanisms to improve industrial competitiveness.

References

G. X. Lai, W. F. Su and G. X. Lin, The mode clamping mechanism of servo-drive type injection molding machine, Taiwan patent, 542097, Jul. 11, 2003.

F. Q. Jiang, Driving device of controlling mode opening and closing for plastic molding machine, Taiwan patent, M257273, Feb. 21, 2005.

W. T. Chang and L. Y. Wu, Ten-link clamping mechanism with double dead-positions, Taiwan patent, I382913, Jan. 21, 2013.

J. Li and G.W. Li, All-electric plastic injection machine, Taiwan patent, M510231, Oct. 11, 2015.

W. Y. Lin, Y. C. Chang, Z. Cheng, X. R. Chen, and H. Y. Chen, New fast five-point locking mechanism with two dead-position configurations, Taiwan patent, M510233, Oct. 11, 2015.

Y. Y Chen and J. C. Qin, Clamping device for mold, Taiwan patent, I537121, Jun. 11, 2016.

W. Y. Lin, Y. C. Chang, and Y. J. Xiao, New five-point clamping mechanism with two dead-position configurations for injection molding machine, Taiwan patent, M541943, Mar. 21, 2017.

H. S. Yan, “A methodology for creative mechanism design,” Mechanism and Machine Theory, vol. 27, no. 3, pp. 235-242, May. 1992.

H. S. Yan, Creative Design of Mechanical Devices, Springer-Verlag, Singapore, 1998.

W. H. Hsieh and S. J. Chen, “Innovative Design of Cam-Controlled Planetary Gear Trains,” International Journal of Engineering and Technology Innovation, vol. 1, no. 1, pp. 01-11, 2011.

L. C. Hsieh and T. H. Chen, “The Systematic Design of Link-Type Optical Fiber Polisher with Single Flat,” Journal of Advanced Science Letters, vol. 9, pp. 318-324, 2012.

G. S. Hwang and C. C. Lin, “Innovative Design of a Transmission Mechanism for Variable Speed Wind Turbines,” JSME Journal of Advanced Mechanical Design, Systems, and Manufacturing, vol.9, no.3, pp. 1-11, 2015.

T. H. Chen and L.C. Hsieh, “The Innovative Design of the Massage Mechanisms for Massage Chair,” Advances in Technology Innovation, vol. 4, no. 2, pp. 116-124, 2019.

Z. F. Yuan, M. J. Gilmartin, and S. S. Douglas, “Optimal Mechanism Design for Path Generation and Motions with Reduced Harmonic Content,” ASME Transactions, Journal of Mechanical Design, vol. 126, no. 1, pp. 191-196, 2004.

W. H. Hsieh, “Kinematic synthesis of cam-controlled planetary gear trains,” Mechanism and Machine Theory, vol. 44, no. 5, pp. 873–895, 2009.

H. Li and Y. Zhang, “Seven-bar mechanical press with hybrid-driven mechanism for deep drawing; Part 1: Kinematic analysis and optimum design,” Journal of Mechanical Science and Technology, vol. 24, no.11, pp.2513-2160, 2010.

W. H. Hsieh and C. H. Tsai, “On a Novel Press System with Six Links for Precision Deep Drawing,” Mechanism and Machine Theory, vol. 46, no. 2, pp. 239–252, 2011.

L. C. Hsieh and T. H. Chen, “The Systematic Design of Link-Type Optical Fiber Polisher with Single Flat,” Journal of Advanced Science Letters, vol. 9, pp. 318-324, 2012.

L. C. Hsieh and T. H. Chen, “The Systematic Design of Planetary-Type Grinding devices for Optical fiber ferrules and wafers,” Transactions of the Canadian Society for Mechanical Engineering, vol. 40, no. 4, pp. 619-630, 2016.

F. C. Chen, Y. F. Tzeng, and W. R. Chen, “On the Mechanism Design of an Innovative Elliptical Exerciser with Quick-Return Effect,” International Journal of Engineering and Technology Innovation, vol. 8, no. 3, pp. 228-239, 2018.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.