An Experimental Study of Plastic Waste as Fine Aggregate Substitute for Environmentally Friendly Concrete

DOI:

https://doi.org/10.46604/aiti.2021.6930Keywords:

environmentally friendly concrete, plastic waste, compressive strengthAbstract

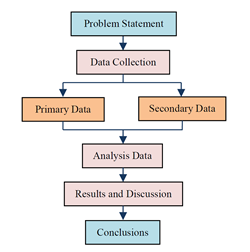

Decomposing plastics, including plastic bottles, is a very difficult process because it takes 50-100 years. Every year, the use of plastic bottles is increasing, but only few people are willing to treat plastic bottle waste. In this study, plastic bottle waste is used as a substitute of fine aggregate and shaped in such a way to have a sand-like gradation. The variations of graded plastic bottle waste are 0%, 5%, 10%, and 12%. The test objects for each variation consist of three specimens. Data are analyzed by using regression and classical assumption test with SPSS program. The results of the data analysis show that there is a simultaneous effect on the compressive strength with variations in plastic waste substitution. The compressive strength decreases with the increase in the percentage of plastic added. Maximum compressive strength is at the variations of 0% and 5% with19.192 MPa and 16.414 MPa, respectively.

References

M. Guendouz, F. Debieb, O. Boukendakdji, E. H. Kadri, M. Bentchikou, and H. Soualhi, “Use of Plastic Waste in Sand Concrete,” Journal of Materials and Environmental Science, vol. 7, no. 2, pp. 382-389, October 2016.

A. I. N. Diana and H. Depriyanto, “The Effect of Using Economic Plastic Fiber (Eco Plafie) Paving Block on Compressive Strength, Shock Resistance, and Water Absorption as Environmentally Friendly Products,” National Conference on Mathematics, Science and Education, Madura Islamic University Press, October 2018, pp. 19-26.

H. Karimah, “Experimental Study of the Effect of LDPE Cast Plastic Content on the Compressive Strength of Normal Strength Concrete,” Thesis, Department Civil Engineering, Parahyangan Catholic University, Bandung, Jawa Barat, 2018.

Alvine, “Experimental Study of the Effect of ABS Plastic Waste as a Partial Substitution of Concrete Aggregates with a Design Compressive Strength of F’c = 35 MPa,” Thesis, Department Civil Engineering, Parahyangan Catholic University, Bandung, Jawa Barat, 2019.

S. Suleman and S. Needhidasan, “Utilization of Manufactured Sand as Fine Aggregates in Electronic Plastic Waste Concrete of M30 Mix,” Materials Today, vol. 33, no. 1, pp. 1192-1197, September 2020.

B. V. Bahoria, D. K. Parbat, and P. B. Nagarnaik, “XRD Analysis of Natural Sand, Quarry Dust, Waste Plastic (LDPE) to be Used as a Fine Aggregate in Concrete,” Materials Today, vol. 5, no.1, pp. 1432-1438, February 2018.

S. S. Mathi, V. Johnpaul, R. Sindhu, P. R. Riyas, and N. Chidambaram, “Mechanical Properties of Concrete with Plastic as Partial Replacement of Fine Aggregate,” Materials Today: Proceedings, in press.

Z. C. Steyn, A. J. Babafemi, H. Fataar, and R. Combrinck, “Concrete Containing Waste Recycled Glass, Plastic, and Rubber as Sand Replacement,” Construction and Building Materials, vol. 269, 121242, February 2021.

A. Evram, T. Akçaoğlu, K. Ramyar, and B. Çubukçuoğlu, “Effects of Waste Electronic Plastic and Marble Dust on Hardened Properties of High Strength Concrete,” Construction and Building Materials, vol. 263, no. 1, pp. 1-10, September 2020.

X. Li, T. C. Ling, and K. H. Mo, “Functions and Impacts of Plastic/Rubber Wastes as Eco-Friendly Aggregate in Concrete—A Review,” Construction and Building Materials, vol. 240, no. 1, pp. 1-13, December 2019.

Y. Adela, M. Behanu, and B. Gobena, “Plastic Wastes as a Raw Material in the Concrete Mix: An Alternative Approach to Manage Plastic Wastes in Developing Countries,” International Journal of Waste Resources, vol. 10, no. 382, pp. 1-7, June 2020.

S. Fansuri and A. I. N. Diana, “Characteristics of Coarse Aggregate and Fine Aggregate for Building Materials in Sumenep Regency,” National Conference on Mathematics, Science, and Education, Madura Islamic University Press, October 2018, pp. 9-18.

Method of Test for Specific Gravity and Water Absorption of Fine Aggregate, Indonesian National Standard 1970, 2008.

Test Method for Fine Aggregate and Coarse Aggregate Sieve Analysis, Indonesian National Standard ASTM C136, 2012.

Method of Test for Specific Gravity and Water Absorption of Coarse Aggregate, Indonesian National Standard 1969, 2008.

Procedure for Making a Normal Concrete Mix Plan, Indonesian National Standard 03-2834, 2000.

How to Test a Concrete Slump, Indonesian National Standard 1972, 2008.

How to Test Concrete Compressive Strength with Cylindrical Test Objects, Indonesian National Standard 1974, 2011.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.