Piglets Comfort with Hot Water by Biogas Combustion under Controllable Ventilation

Keywords:

biogas, piglets, hot-water heating system, force ventilationAbstract

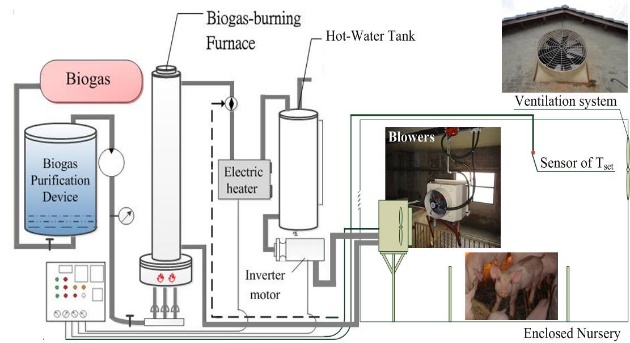

The purpose of this study is to develop a hot-water heating system for pig farms which use biogas as the energy source while the air quality is regulated using an inverter-controlled fan. The biogas is a by-product from the 3-stage wastewater treatment process in regular pig farms. The biogas is burned for hot water which is circulated to warm piglet compartments with regulated, forced ventilation. The hot water is connected to a heat exchanger and hot air is hence blown into the pigsty. To maintain the pigsty at a comfort atmosphere, ventilation is regulated using an inverter-controlled fan. The mechanical ventilation is to be optimized as a compromise between indoor air quality and ventilation rate. The temperature uniformity and air quality in the pigsty is to be secured for comfortability. Experimental results show that hot water circulating at 0.043 m3/min and 60°C could keep the pigsty at 28°C for a stocking density of 1.77 pig/m2. Forced ventilation of 1.7 ACH (air change rate per hour) at 28°C could keep the pigsty comfort in terms of indoor temperature, relative humidity, and carbon-dioxide concentration.

References

P. V. Rao, S. B. Saroj, R. Dey, and S. Mutnuri “Biogas generation potential by anaerobic digestion for sustainable energy development in india,” Renewable and Sustainable Energy Reviews, vol. 14, no. 7, pp. 2086-2094, September 2010.

M. Van Haren and R. Fleming, “Electricity and heat production using biogas from the anaerobic digestion of livestock manure-literature review,” University of Guelph, Ridgetown College, 2005.

J. B. Holm-Nielsen, T. A. Seadi, and P. Oleskowicz-Popiel, “The future of anaerobic digestion and biogas utilization,” Bioresource Technology, vol. 100, no. 22, pp. 5478-5484, November 2009.

R. C. Saxena, D. K. Adhikari, and H. B. Goyal, “Biomass-based energy fuel through biochemical routes: a review,” Renewable and Sustainable Energy Reviews, vol. 13, no. 1, pp. 167-178, January 2009.

C. C. Su, C. M. Hong, M. T. Koh, and S. Y. Sheen, “Swine waste treatment in taiwan,” Department of Livestock Management, Taiwan Livestock Research Institute, 1994.

H. Pandorfi and I. J. O. da Silva, “Evaluation of the behavior of piglets in different heating systems using analysis of image and electronic identification,” Agricultural Engineering International, 2005.

K. Donham, P. Haglind, Y. Peterson, R. Rylander, and L. Belin, “Environmental and health studies of farm workers in swedish swine confinement buildings,” British Journal of Industrial Medicine, vol. 46, no. 1, pp. 31-37, January 1989.

A. J. Heber, J. Q. Ni, B. L. Haymore, R. K. Duggirala, and K. M. Keener, “Air quality and emission measurement methodology at swine finishing buildings,” Transactions of the American Society of Agricultural Engineers , vol. 44, no. 6, pp. 1765-1778, January 2001.

G. P. A. Bot and J. H. M. Metz, “Measurement, evaluation and control of the microclimate in rooms for weaned piglets,” In: A. V. Van Wagenberg, J. M. Aerts, A. Van Brecht, E. Vranken, T. Leroy, D. Berckmans, “Climate Control Based On Temperature Measurement In The Animal-Occupied Zone Of A Pig Room With Ground Channel Ventilation,” Transactions of American Society of Agricultural Engineers, vol. 48, pp. 111-125, January 2005.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.