A CAD-Driven and Cloud-Based Autonomous Process Planning Framework for Reconfigurable Bending Press Machines

DOI:

https://doi.org/10.46604/peti.2024.14044Keywords:

digital manufacturing, process planning, sheet metal, reconfigurable bending press machine (RBPM)Abstract

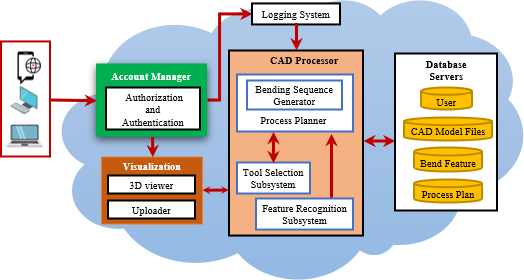

Sheet metal part manufacturers are increasingly under pressure to meet highly variable consumer demands. As product customization increases, the production process for sheet metal bending parts becomes more complex. This article proposes a fully integrated cloud-based system for sheet metal process planning. The system is developed based on a computer-aided design application and has the capability to rapidly convert a standard for the exchange of product data (STEP) file manufacturing instructions. A new mathematical model for calculating the overall production cycle time is also formulated. Two sheet metal components are used to test the system. The results demonstrate that the proposed cloud-based framework can display the 3D model, its face relationships, and a table containing the manufacturing information.

References

N. Gwangwava, K. Mpofu, N. Tlale, and Y. Yu, “Sheet Metal Productivity Improvement through a New Press Brake Design,” African Journal of Science, Technology, Innovation and Development, vol. 6, no. 2, pp. 135-144, 2014.

J. Li, G. Zhou, C. Zhang, J. Hu, F. Chang, and A. Matta, “Defining a Feature-Level Digital Twin Process Model by Extracting Machining Features from MBD Models for Intelligent Process Planning,” Journal of Intelligent Manufacturing, in press.

Y. Yang, T. Hu, Y. Ye, W. Gao, and C. Zhang, “A Knowledge Generation Mechanism of Machining Process Planning Using Cloud Technology,” Journal of Ambient Intelligence and Humanized Computing, vol. 10, pp. 1081-1092, 2019.

F. Lupi, N. Freitas, M. Arvana, A. D. Rocha, A. Maffei, J. Barata, et al., “Next-Generation Vision Inspection Systems: A Pipeline from 3D Model to ReCo File,” Journal of Intelligent Manufacturing, in press.

F. Lupi, M. Biancalana, A. Rossi, and M. Lanzetta, “A Framework for Flexible and Reconfigurable Vision Inspection Systems,” The International Journal of Advanced Manufacturing Technology, vol. 129, pp. 871-897, 2023.

S. Liu, Y. Xia, Z. Shi, H. Yu, Z. Li, and J. Lin, “Deep Learning in Sheet Metal Bending with a Novel Theory-Guided Deep Neural Network,” IEEE/CAA Journal of Automatica Sinica, vol. 8, no. 3, pp. 565-581, 2021.

A. Jemal, A. O. Salau, and A. Wondimu, “Finite Element Method-Based Multi-Objective Optimization of Press-Brake Bending of Sheet Metal,” The International Journal of Advanced Manufacturing Technology, vol. 130, pp. 4263-4275, 2024.

Y. Yang and S. Hinduja, “Sequence Planning of Sheet Metal Parts Manufactured Using Progressive Dies,” The International Journal of Advanced Manufacturing Technology, vol. 124, pp. 2199-2214, 2023.

F. Xu, D. Ding, B. Fan, and S. Yang, “Prediction of Bending Parameters and Automated Operation Planning for Sheet-Metal Bending Orientated to Graphical Programming,” The International Journal of Advanced Manufacturing Technology, vol. 126, pp. 2191-2204, 2023.

D. Cattrysse, P. Beullens, P. Collin, J. Duflou, and D. Van Oudheusden, “Automatic Production Planning of Press Brakes for Sheet Metal Bending,” International Journal of Production Research, vol. 44, no. 20, pp. 4311-4327, 2006.

J. R. Duflou, J. Váncza, and R. Aerens, “Computer-Aided Process Planning for Sheet Metal Bending: A State of the Art,” Computers in industry, vol. 56, no. 7, pp. 747-771, 2005.

A. Márkus, J. Váncza, and A. Kovács, “Constraint-Based Process Planning in Sheet Metal Bending,” CIRP Annals, vol. 51, no. 1, pp. 425-428, 2002.

L. De Vin, J. De Vries, and T. Streppel, “Process Planning for Small Batch Manufacturing of Sheet Metal Parts,” International Journal of Production Research, vol. 38, no. 17, pp. 4273-4283, 2010.

M. Shpitalni and B. Radin, “Critical Tolerance Oriented Process Planning in Sheet Metal Bending,” Journal of Mechanical Design, vol. 121, no. 1, pp. 136-144, 1999.

J. Duflou, J. P. Kruth, and D. Van Oudheusden, “Algorithms for the Design Verification and Automatic Process Planning for Bent Sheet Metal Parts,” CIRP Annals, vol. 48, no. 1, pp. 405-408, 1999.

S. K. Gupta, D. A. Bourne, K. H. Kim, and S. S. Krishnan, “Automated Process Planning for Sheet Metal Bending Operations,” Journal of Manufacturing Systems, vol. 17, no. 5, pp. 338-360, 1998.

S. Kumar, R. Singh, D. Panghal, S. Salunkhe, and H. M. A. Hussein, Feature Extraction and Manufacturability Assessment of Sheet Metal Parts, New York: Springer, 2016.

A. A. Salem, T. F. Abdelmaguid, A. S. Wifi, and A. Elmokadem, “Towards an Efficient Process Planning of the V-Bending Process: An Enhanced Automated Feature Recognition System,” The International Journal of Advanced Manufacturing Technology, vol. 91, pp. 4163-4181, 2017.

T. R. Kannan and M. S. Shunmugam, “Processing of 3D Sheet Metal Components in STEP AP-203 Format. Part II: Feature Recognition System,” International Journal of Production Research, vol. 47, no. 5, pp. 1287-1308, 2009.

A. C. Lin and C. F. Chen, “Sequence Planning and Tool Selection for Bending Processes of 2.5 D Sheet Metals,” Advances in Mechanical Engineering, vol. 6, article no. 204930, 2014.

T. H. M. Nguyen, J. R. Duflou, and J. P. Kruth, “A Framework for Automatic Tool Selection in Integrated Capp for Sheet Metal Bending,” Advanced Materials Research, vol. 6-8, pp. 287-294, 2005.

J. R. Duflou, T. H. M. Nguyen, J. P. Kruth, and D. Cattrysse, “Automated Tool Selection for Computer-Aided Process Planning in Sheet Metal Bending,” CIRP Annals, vol. 54, no. 1, pp. 451-454, 2005.

G. N. Nikolov, A. N. Thomsen, A. F. Mikkelstrup, and M. Kristiansen, “Computer-Aided Process Planning System for Laser Forming: From CAD to Part,” International Journal of Production Research, vol. 62, no. 10, pp. 3526-3543, 2024.

J. Jiang, Z. Li, Y. Zhang, S. Chen, and Y. Hu, “Process Planning for Laser Peen Forming of Complex Geometry: An Analytical-Based Inverse Study,” Thin-Walled Structures, vol. 204, article no. 112274, 2024.

M. Luo, Y. Hu, L. Hu, and Z. Yao, “Efficient Process Planning of Laser Peen Forming for Complex Shaping with Distributed Eigen-Moment,” Journal of Materials Processing Technology, vol. 279, article no. 116588, 2020.

M. Givehchi, A. Haghighi, and L. Wang, “Cloud-Dpp for Distributed Process Planning of Mill-Turn Machining Operations,” Robotics and Computer-Integrated Manufacturing, vol. 47, pp. 76-84, 2017.

D. Mourtzis, E. Vlachou, N. Xanthopoulos, M. Givehchi, and L. Wang, “Cloud-Based Adaptive Process Planning Considering Availability and Capabilities of Machine Tools,” Journal of Manufacturing Systems, vol. 39, pp. 1-8, 2016.

L. Wang, “Machine Availability Monitoring and Machining Process Planning Towards Cloud Manufacturing,” CIRP Journal of Manufacturing Science and Technology, vol. 6, no. 4, pp. 263-273, 2013.

E. Murena, K. Mpofu, A. T. Ncube, O. Makinde, J. A. Trimble, and X. V. Wang, “Development and Performance Evaluation of a Web-Based Feature Extraction and Recognition System for Sheet Metal Bending Process Planning Operations,” International Journal of Computer-Integrated Manufacturing, vol. 34, no. 6, pp. 598-620, 2021.

E. Murena, K. Mpofu, and W. Dube, “A Novel Feature-Based Bending Sequence Planning for Sheet Metal Components for Rail Parts,” International Journal of Applied Engineering & Technology, vol. 6, no. 1, pp. 1792-1809, 2024.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Eriyeti Murena, Khumbulani Mpofu, Gift Nenzhelele, Mr Wilfred Dube

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright of their article with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Oct. 01, 2015, PETI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes