Integration of Membrane Bioreactor and Reverse Osmosis for Textile Wastewater Treatment and Reclamation: A Pilot-Scale Study

DOI:

https://doi.org/10.46604/peti.2023.5273Keywords:

membrane bioreactor, textile wastewater, reverse osmosis, transmembrane pressureAbstract

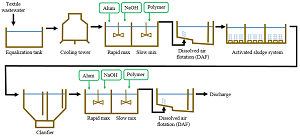

Membrane bioreactor (MBR) technology, a combination of traditional activated sludge and membrane filtration, has been widely used for industrial wastewater treatment and reclamation. This paper highlights a pilot-scale MBR system treating textile wastewater from a textile factory in Taiwan. Over 7 months of continuous operation, the average MBR influent chemical oxygen demand (COD) is 332 mg/L, and the average effluent COD is 38 mg/L, which results in approximately 88% COD removal. A reverse osmosis (RO) module is installed after 2 months of MBR operation and uses the MBR permeate as its influent. The RO produces pure water with average COD, conductivity, and color of 7 mg/L, 16 μS/cm, and 7 Pt-Co, respectively. The RO permeate is suitable for reuse in manufacturing processes, and the RO membrane shows stable performance with TMP, which is less than or equal to 0.5 kg/cm2 during the test. The study demonstrates the great feasibility of MBR combined with RO for treating and reclaiming textile wastewater.

References

H. Ali, “Biodegradation of Synthetic Dyes—A Review,” Water, Air, & Soil Pollution, vol. 213, no. 1-4, pp. 251-273, November 2010.

D. A. Yaseen and M. Scholz, “Textile Dye Wastewater Characteristics and Constituents of Synthetic Effluents: a Critical Review,” International Journal of Environmental Science and Technology, vol. 16, no. 2, pp. 1193-1226, February 2019.

M. K. Shahid, A. Kashif, P. Pathak, Y. Choi, and P. R. Rout, “Water Reclamation, Recycle, and Reuse,” Clean Energy and Resource Recovery: Wastewater Treatment Plants as Biorefineries, vol. 2, pp. 39-50, 2022.

N. C. Cinperi, E. Ozturk, N. O. Yigit, and M. Kitis, “Treatment of Woolen Textile Wastewater Using Membrane Bioreactor, Nanofiltration and Reverse Osmosis for Reuse in Production Processes,” Journal of Cleaner Production, vol. 223, pp. 837-848, June 2019.

L. M. L. K. B. Lindamulla, V. Jegatheesan, K. B. S. N. Jinadasa, K. G. N. Nanayakkara, and M. Z. Othman, “Integrated Mathematical Model to Simulate the Performance of a Membrane Bioreactor,” Chemosphere, vol. 284, article no. 131319, December 2021.

C. V. Faria, B. C. Ricci, A. F. R. Silva, M. C. S. Amaral, and F. V. Fonseca, “Removal of Micropollutants in Domestic Wastewater by Expanded Granular Sludge Bed Membrane Bioreactor,” Process Safety and Environmental Protection, vol. 136, pp. 223-233, April 2020.

S. Kitanou, M. Tahri, B. Bachiri, M. Mahi, M. Hafsi, M. Taky, et al., “Comparative Study of Membrane Bioreactor (MBR) and Activated Sludge Processes in the Treatment of Moroccan Domestic Wastewater,” Water Science and Technology, vol. 78, no. 5, pp. 1129-1136, October 2018.

A. Yurtsever, E. Basaran, D. Ucar, and E. Sahinkaya, “Self-Forming Dynamic Membrane Bioreactor for Textile Industry Wastewater Treatment,” Science of The Total Environment, vol. 751, article no. 141572, January 2021.

A. Sengar and A. Vijayanandan, “Effects of Pharmaceuticals on Membrane Bioreactor: Review on Membrane Fouling Mechanisms and Fouling Control Strategies,” Science of The Total Environment, vol. 808, article no. 152132, February 2022.

M. Wu, Y. Chen, H. Lin, L. Zhao, L. Shen, R. Li, et al., “Membrane Fouling Caused by Biological Foams in a Submerged Membrane Bioreactor: Mechanism Insights,” Water Research, vol. 181, article no. 115932, August 2020.

M. Brik, P. Schoeberl, B. Chamam, R. Braun, and W. Fuchs, “Advanced Treatment of Textile Wastewater towards Reuse Using a Membrane Bioreactor,” Process Biochemistry, vol. 41, no. 8, pp. 1751-1757, August 2006.

P. Krzeminski, L. Leverette, S. Malamis, and E. Katsou, “Membrane Bioreactors – A Review on Recent Developments in Energy Reduction, Fouling Control, Novel Configurations, LCA and Market Prospects,” Journal of Membrane Science, vol. 527, pp. 207-227, April 2017.

S. Al-Asheh, M. Bagheri, and A. Aidan, “Membrane Bioreactor for Wastewater Treatment: A Review,” Case Studies in Chemical and Environmental Engineering, vol. 4, article no. 100109, December 2021.

C. Lubello and R. Gori, “Membrane Bio-Reactor for Advanced Textile Wastewater Treatment and Reuse,” Water Science and Technology, vol. 50, no. 2, pp. 113-119, July 2004.

P. Schoeberl, M. Brik, M. Bertoni, R. Braun, and W. Fuchs, “Optimization of Operational Parameters for a Submerged Membrane Bioreactor Treating Dyehouse Wastewater,” Separation and Purification Technology, vol. 44, no. 1, pp. 61-68, July 2005.

N. O. Yigit, N. Uzal, H. Koseoglu, I. Harman, H. Yukseler, U. Yetis, et al., “Treatment of a Denim Producing Textile Industry Wastewater Using Pilot-Scale Membrane Bioreactor,” Desalination, vol. 240, no. 1-3, pp. 143-150, May 2009.

X. Zheng and J. Liu, “Dyeing and Printing Wastewater Treatment Using a Membrane Bioreactor with a Gravity Drain,” Desalination, vol. 190, no. 1-3, pp. 277-286, April 2006.

K. Li, Q. Liu, F. Fang, X. Wu, J. Xin, S. Sun, et al., “Influence of Nanofiltration Concentrate Recirculation on Performance and Economic Feasibility of a Pilot-Scale Membrane Bioreactor-Nanofiltration Hybrid Process for Textile Wastewater Treatment with High Water Recovery,” Journal of Cleaner Production, vol. 261, article no. 121067, July 2020.

O. K. Abass, F. Fang, M. Zhuo, and K. Zhang, “Integrated Interrogation of Causes of Membrane Fouling in a Pilot-Scale Anoxic-Oxic Membrane Bioreactor Treating Oil Refinery Wastewater, ” Science of The Total Environment, vol. 642, pp. 77-89, November 2018.

S. H. Zahraa, H. A. Gzar, and H. H. Shaimaa, “Evaluation of Laboratory Submerged Membrane Bioreactor and Reverse Osmosis System for Treating Textile Wastewater and Reuse,” Journal of Physics: Conference Series, vol. 1973, article no. 012185, August 2021.

S. K. Tseng, “The Effect of Grease on the Activated Sludge Process in Wastewater Treatment,” Journal of the Chinese Institute of Engineers, vol. 2, no. 2, pp. 143-149, May 1979.

I. S. Chang, P. L. Clech, B. Jefferson, and S. Judd, “Membrane Fouling in Membrane Bioreactors for Wastewater Treatment,” Journal of Environmental Engineering, vol. 128, no. 11, pp. 1018-1029, November 2002.

V. Jegatheesan, B. K. Pramanik, J. Chen, D. Navaratna, C. Y. Chang, and L. Shu, “Treatment of Textile Wastewater with Membrane Bioreactor: A Critical Review,” Bioresource Technology, vol. 204, pp. 202-212, March 2016.

J. Hoinkis, S. A. Deowan, V. Panten, A. Figoli, R. R. Huang, and E. Drioli, “Membrane Bioreactor (MBR) Technology – a Promising Approach for Industrial Water Reuse,” Procedia Engineering, vol. 33, pp. 234-241, 2012.

A. Rozzi, F. Malpei, L. Bonomo, and R. Bianchi, “Textile Wastewater Reuse in Northern Italy (COMO),” Water Science and Technology, vol. 39, no. 5, pp. 121-128, 1999.

P. Schoeberl, M. Brik, R. Braun, and W. Fuchs, “Treatment and Recycling of Textile Wastewater—Case Study and Development of a Recycling Concept,” Desalination, vol. 171, no. 2, pp. 173-183, January 2005.

F. Ismail, K. C. Khulbe, and T. Matsuura, Reverse Osmosis, 1st ed, Amsterdam: Elsevier, 2018.

M. Tawalbeh, L. Qalyoubi, A. Al-Othman, M. Qasim, and M. Shirazi, “Insights on the Development of Enhanced Antifouling Reverse Osmosis Membranes: Industrial Applications and Challenges,” Desalination, vol. 553, article no. 116460, May 2023.

The Water Pollution Control Act, Effluent Standards 14, 2019.

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Po-Hsun Lin, Pin-Hui Lee, Emily K. Kin

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright of their article with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Oct. 01, 2015, PETI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes