Genetic Based Experimental Investigation on Finishing Characteristics of AlSiCp-MMC by Abrasive Flow Machining

DOI:

https://doi.org/10.46604/ijeti.2020.4951Keywords:

abrasive flow machining, mmc, polishing, genetic models, forecastingAbstract

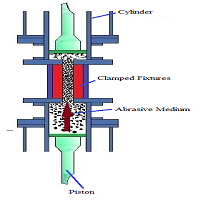

Implementing non-conventional finishing methods in the aircraft industry by the abrasive flow machining (AFM) process depends on the production quality at optimal conditions. The optimal set of the process variables in metal-matrix-composite (MMC) for a varying reinforcement percentage removes the obstructions and errors in the AFM process. In order to achieve this objective, the resultant output functions of the overall process using every clustering level of variables in a model are configured by using genetic programming (GP). These functions forecast the data to vary the percent of silicon carbide particles (particles without experimentation obtaining the output functions for material removing rates and surface roughness changes of Al-MMCs machined with the AFM process by using GP. The obtained genetic optimal global models are simulated and, the results show a higher degree of accuracy up to 99.97% as compared to the other modeling techniques.

References

V. K. Jain, Micro manufacturing processes, 1st ed. Florida: Boca Raton, 2012.

R. K. Jain, V. K. Jain, and P. M. Dixit, “Modeling of material removal and surface roughness in the abrasive flow machining process,” International Journal of Machine Tools and Manufacture, vol. 39, no. 12, pp. 1903-1923, August 1999.

W. Zhenlong, G. Xuesong, C. Guanxin, and W. Yukui, “Surface integrity associated with SiCp/Al particulate composite by micro-wire electrical discharge machining,” Materials and Manufacturing Processes, vol. 29, no. 5, pp. 532-539, April 2014.

A. C. Wang and S. H. Weng, “Developing the polymer abrasive gels in AFM process,” Journal of Materials Processing Technology, vol. 192, pp. 486-490, April 2007.

V. K. Jain, “Magnetic field assisted abrasive based micro-/nano-finishing,” Journal of Materials Processing Technology, vol. 209, no. 20, pp. 6022-6038, August 2009.

J. Kenda, F. Pusavec, G. Kermouche, and J. Kopac “Surface integrity in abrasive flow machining of hardened tool steel AISI D2,” Procedia Engineering, vol. 19, pp. 172-177, November 2011.

K. B. Judal, V. Yadava, and D. Pathak, “Experimental investigation of vibration assisted cylindrical–magnetic abrasive finishing of aluminum workpiece,” Materials and Manufacturing Processes, vol. 28, no. 11, pp. 1196-1202, November 2013.

M. Das, V. K. Jain, and P. S. Ghoshdastidar, “The out-of-roundness of the internal surfaces of stainless steel tubes finished by the rotational–magnetorheological abrasive flow finishing process,” Materials and Manufacturing Processes, vol. 26, no. 8, pp. 1073-1084, August 2011.

R. S. Mulik and P. M. Pandey, “Experimental investigations and modeling of finishing force and torque in ultrasonic assisted magnetic abrasive finishing,” Journal of Manufacturing Science and Engineering, vol. 134, no. 5, article 051008, September 2012.

V. K. Jain and S. G. Adsul, “Experimental investigations into abrasive flow machining,” International Journal of Machine Tools and Manufacture, vol. 40, no. 7, pp. 1003-1021, March 2000.

H .J. Tzeng, B. H. Yan , R. T. Hsu, and H. M. Chow “Finishing effect of abrasive flow machining on micro slit fabricated by wire-EDM,” The International Journal of Advanced Manufacturing Technology, vol. 34, no. 7-8, pp. 649-656, August 2007.

S. S. Sidhu, A. Batish, and S. Kumar, “Study of surface properties in particulate-reinforced metal matrix composites using powder-mixed electrical discharge machining,” Materials and Manufacturing Processes, vol. 29, no. 1, pp. 46-52, February 2014.

X. Yin and K. Komvopoulos, “A slip-line plasticity analysis of abrasive wear of a smooth and soft surface sliding against a rough (fractal) and hard surface,” International Journal of Solids and Structures, vol. 49, no. 1, pp. 121-131, September 2012.

J. N. Muguthu and D. Gao, “Profile fractal dimension and dimensional accuracy analysis in machining metal matrix composites,” Materials and Manufacturing Processes, vol. 28, no. 10, pp. 1102-1109, 2013.

M. Yunus and M. S. Alsoufi, “Application of response surface methodology for the optimization of the control factors of abrasive flow machining of multiple holes in Zinc and Al/SiCp MMC wires,” Journal of Engineering Science and Technology, vol. 15, no. 1, pp. 655-674, February 2020.

M. R. Sankar, V. K. Jain, J. Ramkumar, and Y. M. Joshi, “Rheological characterization of styrene-butadiene based medium and its finishing performance using rotational abrasive flow finishing process,” International Journal of Machine Tools and Manufacture, vol. 51, no. 12, pp. 947-957, August 2011.

A. Kumar, V. Kumar, and J. Kumar, “Multi-response optimization of process parameters based on response surface methodology for pure titanium using WEDM process,” International Journal of Advanced Manufacturing Technology, vol. 68, no. 9-12, pp. 2645-2668, March 2013.

J. R. Koza, “Genetic programming as a means for programming computers by natural selection,” Statistics and Computing, vol. 4, no. 2, pp. 87-112, June 1994.

S. Singh, P. Kumar, and H. S. Shan, “Quality optimization of surface finishing by magnetic field assisted abrasive flow machining through Taguchi technique,” International Journal of Computing Application Technology, vol. 27, no. 1, pp. 31-37, September 2006.

M. Gostimirovic, V. Pucovsky, M. Sekulic, D. Rodic, and V. Pejic, “Evolutionary optimization of jet lag in the abrasive water jet machining,” International Journal of Advanced Manufacturing Technology, vol. 101, no. 9-12, pp. 3131-3141, December 2018.

S. Singh and H. S. Shan, “Development of magneto abrasive flow machining process,” International Journal of Machine Tools and Manufacture, vol. 42, no. 8, pp. 953-959, March 2002.

M. R. Sankar, J. Ramkumar, and V. K. Jain, “Experimental investigation and mechanism of material removal in nano finishing of MMCs using abrasive flow finishing (AFF) process,” Wear, vol. 266, no. 7-8, pp. 688-698, October 2008.

J. Li, L. Yang, W. Liu, X. Zhang, and F. Sun, “Experimental research into technology of abrasive flow machining nonlinear tube runner,” Advances in Mechanical Engineering, vol. 6, article 752353, February 2015.

M. Yunus and M. S. Alsoufi, “Mathematical modeling of multiple quality characteristics of a laser micro drilling process used in Al7075/SiCp metal matrix composite using genetic programming,” Modelling and Simulation in Engineering, vol. 2019, pp.1-15, January 2019.

M. Brezocnik, M. Kovacic, and M. Ficko, “Prediction of surface roughness with genetic programming,” Journal of Materials Processing Technology, vol.157–158, pp. 28-36, December 2004.

B. Jabbaripour, M. H. Sadeghi, Sh. Faridvand, and M. R. Shabgard “Investigating the effects of EDM parameters on surface integrity, MRR and TWR in machining of Ti–6Al–4V,” Machining Science and Technology, vol. 16, no. 3, pp. 419-444, August 2012.

J. R. Koza, Genetic programming: on the programming of computers by natural selection, Cambridge, Massachusetts: MIT Press, 1992.

M. Yunus and M. S. Alsoufi, “Mathematical modelling of a friction stir welding process to predict the joint strength of two dissimilar aluminium alloys using experimental data and genetic programming,” Modelling and Simulation in Engineering, vol. 2018, article 4183816, April 2018.

Published

How to Cite

Issue

Section

License

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)