Evaluation of Infill Effect on Mechanical Properties of Consumer 3D Printing Materials

Keywords:

additive manufacturing, polymers, 3D printing, tensile testing, thermoplasticsAbstract

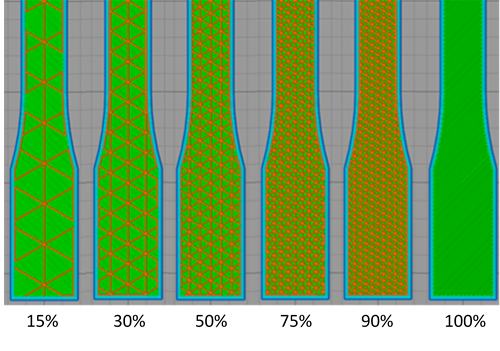

During the additive manufacturing “boom” of the last decade, consumer level 3D printers have kept pace with commercial/industrial printers, both in numbers and features. However, in material characterization data, the access to date for the consumer has significantly lagged behind. Consumer level 3D printers provide a significant asset to entrepreneurs, small businesses, universities, college students, and hobbyists due to the low initial capital cost and relatively low operational costs. Commercial grade 3D printers and the associated filaments sold for their use typically have well documented material properties and print parameters. Consumer 3D printers, however, typically have limited or no access to mechanical test data for their materials. This paper describes the work of the authors to fill the existing knowledge gap in the mechanical properties of consumer level 3D printer filament. ASTM Tensile (D638) tests were performed on samples produced by two commercially available 3D printers. The materials tested include PLA, ABS, PETG, various nylons, Polycarbonate/ABS, and ASA filaments. Samples were printed with infill percentages ranging from 15% to 100% to test for tensile properties.

References

ASTM, ASTM D638-14: standard test method for tensile properties of plastics, 2014.

LULZBOT, “Filament guide,” https://devel.lulzbot.com/filament/Archive/LulzBot_3D_Printing_Filament_Guide.pdf.

O. Olabisi and K. Adewale, Handbook of thermoplastics, 2nd ed. Boca Raton: CRC Press, Taylor & Francis Group, 2016.

3DXTECH, “3DXMAX ASA 3D filament,” http://www.3dxtech.com/content/ASA_Filament_v2.1.pdf.

3DXTECH, “3DXMAX PC/ABS 3D filament,” http://www.3dxtech.com/content/PC-ABS_Filament_v2.1.pdf.

Taulman3D, “Main features,” http://taulman3d.com/main-features.html.

T. Landry, “Beat moisture before it kills your 3D printing filament,” https://www.matterhackers.com/news/filament-and-water.

A. Lanzotti, M. Grasso, G. Staiano, and M. Martorelli, “The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer,” Rapid Prototyping Journal, vol. 21, no. 5, pp. 604-617, 2015.

F. P. Beer, E. R. Johnston, J. T. DeWolf, and D. F. Mazurek, Mechanics of materials, New York: McGraw-Hill, 2012.

MatWeb, “Overview of materials for polylactic acid (PLA) biopolymer,” http://www.matweb.com.

MatWeb, “Overview of materials for acrylonitrile butadiene styrene (ABS), molded,” www.matweb.com.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.