Optimization of Weld Parameters in Wire and Arc-Based Directed Energy Deposition of High Strength Low Alloy Steels

DOI:

https://doi.org/10.46604/aiti.2023.10658Keywords:

WADED, HSLA steel, weld bead, optimal variablesAbstract

This paper aims to investigate the fabrication of high strength low alloy (HSLA) steels by wire and arc-based directed energy deposition (WADED). Firstly, the relationship between the process variables (including the travel speed-V, the current-C, and the voltage-U) and the geometrical characteristics of weld beads (including the bead height (BH), bead width (BW), and melting pool length (MPL)) was investigated. Secondly, the optimal process variables were identified using the desirability approach. The results indicate that voltage-U has the highest impact on BW and MPL, meanwhile the travel speed-V is the most impacting factor on BH. The optimal variables for the WADED process of HSAL steels are V = 0.3 m/min, C = 160 A, and U = 19 V. The component fabricated with the optimal variables is fully dense without spatters and defects, confirming the efficiency of the WADED process for HSLA steels.

References

U. M. Dilberoglu, B. Gharehpapagh, U. Yaman, and M. Dolen, “The Role of Additive Manufacturing in the Era of Industry 4.0,” Procedia Manufacturing, vol. 11, pp. 545-554, 2017.

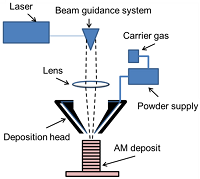

S. M. Thompson, L. Bian, N. Shamsaei, and A. Yadollahi, “An Overview of Direct Laser Deposition for Additive Manufacturing; Part I: Transport Phenomena, Modeling and Diagnostics,” Additive Manufacturing, vol. 8, pp. 36-62, October 2015.

V. T. Le, H. Paris, and G. Mandil, “The Development of a Strategy for Direct Part Reuse Using Additive and Subtractive Manufacturing Technologies,” Additive Manufacturing, vol. 22, pp. 687-699, August 2018.

V. T. Le, H. Paris, and G. Mandil, “Process Planning for Combined Additive and Subtractive Manufacturing Technologies in a Remanufacturing Context,” Journal of Manufacturing Systems, vol. 44, no. 1, pp. 243-254, July 2017.

A. Ramalho, T. G. Santos, B. Bevans, Z. Smoqi, P. Rao, and J. P. Oliveira, “Effect of Contaminations on the Acoustic Emissions during Wire and Arc Additive Manufacturing of 316L Stainless Steel,” Additive Manufacturing, vol. 51, article no. 102585, March 2022.

S. Li, J. Y. Li, Z. W. Jiang, Y. Cheng, Y. Z. Li, S. Tang, et al., “Controlling the Columnar-to-Equiaxed Transition during Directed Energy Deposition of Inconel 625,” Additive Manufacturing, vol. 57, article no. 102958, September 2022.

T. A. Rodrigues, N. Bairrão, F. W. C. Farias, A. Shamsolhodaei, J. Shen, N. Zhou, et al., “Steel-Copper Functionally Graded Material Produced by Twin-Wire and Arc Additive Manufacturing (T-WAAM),” Materials & Design, vol. 213, article no. 110270, January 2022.

V. T. Le, D. S. Mai, M. C. Bui, K. Wasmer, V. A. Nguyen, D. M. Dinh, et al., “Influences of the Process Parameter and Thermal Cycles on the Quality of 308L Stainless Steel Walls Produced by Additive Manufacturing Utilizing an Arc Welding Source,” Welding in the World, vol. 66, no. 8, pp. 1565-1580, August 2022.

D. Jafari, T. H. J. Vaneker, and I. Gibson, “Wire and Arc Additive Manufacturing: Opportunities and Challenges to Control the Quality and Accuracy of Manufactured Parts,” Materials & Design, vol. 202, article no. 109471, April 2021.

S. W. Williams, F. Martina, A. C. Addison, J. Ding, G. Pardal, and P. Colegrove, “Wire + Arc Additive Manufacturing,” Materials Science and Technology, vol. 32, no. 7, pp. 641-647, 2016.

W. E. Frazier, “Metal Additive Manufacturing: A Review,” Journal of Materials Engineering and Performance, vol. 23, no. 6, pp. 1917-1928, June 2014.

J. Xiong, Y. Li, R. Li, and Z. Yin, “Influences of Process Parameters on Surface Roughness of Multi-Layer Single-Pass Thin-Walled Parts in GMAW-Based Additive Manufacturing,” Journal of Materials Processing Technology, vol. 252, pp. 128-136, February 2018.

V. T. Le, “A Preliminary Study on Gas Metal Arc Welding-Based Additive Manufacturing of Metal Parts,” VNUHCM Journal of Science and Technology Development, vol. 23, no. 1, pp. 422-429, February 2020.

V. T. Le, Q. H. Hoang, V. C. Tran, D. S. Mai, D. M. Dinh, and T. K. Doan, “Effects of Welding Current on the Shape and Microstructure Formation of Thin-Walled Low-Carbon Parts Built By Wire Arc Additive Manufacturing,” Vietnam Journal of Science and Technology, vol. 58, no. 4, pp. 461-472, July 2020.

W. Jin, C. Zhang, S. Jin, Y. Tian, D. Wellmann, and W. Liu, “Wire Arc Additive Manufacturing of Stainless Steels: A Review,” Applied Sciences, vol. 10, no. 5, article no. 1563, March 2020.

T. A. Rodrigues, V. Duarte, J. A. Avila, T. G. Santos, R. M. Miranda, and J. P. Oliveira, “Wire and Arc Additive Manufacturing of HSLA Steel: Effect of Thermal Cycles on Microstructure and Mechanical Properties,” Additive Manufacturing, vol. 27, pp. 440-450, May 2019.

J. G. Lopes, C. M. Machado, V. R. Duarte, T. A. Rodrigues, T. G. Santos, and J. P. Oliveira, “Effect of Milling Parameters on HSLA Steel Parts Produced by Wire and Arc Additive Manufacturing (WAAM),” Journal of Manufacturing Processes, vol. 59, pp. 739-749, November 2020.

A. V. Nemani, M. Ghaffari, and A. Nasiri, “Comparison of Microstructural Characteristics and Mechanical Properties of Shipbuilding Steel Plates Fabricated by Conventional Rolling versus Wire Arc Additive Manufacturing,” Additive Manufacturing, vol. 32, article no. 101086, March 2020.

P. Dirisu, S. Ganguly, A. Mehmanparast, F. Martina, and S. Williams, “Analysis of Fracture Toughness Properties of Wire + Arc Additive Manufactured High Strength Low Alloy Structural Steel Components,” Materials Science and Engineering: A, vol. 765, article no. 138285, September 2019.

L. Sun, F. Jiang, R. Huang, D. Yuan, C. Guo, and J. Wang, “Anisotropic Mechanical Properties and Deformation Behavior of Low-Carbon High-Strength Steel Component Fabricated by Wire and Arc Additive Manufacturing,” Materials Science and Engineering: A, vol. 787, article no. 139514, June 2020.

Q. Fang, L. Zhao, B. Liu, C. Chen, Y. Peng, Z. Tian, et al., “Microstructure and Mechanical Properties of 800-MPa-Class High-Strength Low-Alloy Steel Part Fabricated by Wire Arc Additive Manufacturing,” Journal of Materials Engineering and Performance, 2022. https://doi.org/10.1007/s11665-022-06784-7

V. T. Le, D. S. Mai, and Q. H. Hoang, “A Study on Wire and Arc Additive Manufacturing of Low-Carbon Steel Components: Process Stability, Microstructural and Mechanical Properties,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 42, no. 9, article no. 480, September 2020.

V. T. Le, D. S. Mai, T. K. Doan, and Q. H. Hoang, “Prediction of Welding Bead Geometry for Wire Arc Additive Manufacturing of SS308l Walls Using Response Surface Methodology,” Transport and Communications Science Journal, vol. 71, no. 4, pp. 431-443, May 2020.

Z. Wang, S. Zimmer-Chevret, F. Léonard, and G. Abba, “Prediction of Bead Geometry with Consideration of Interlayer Temperature Effect for CMT-Based Wire-Arc Additive Manufacturing,” Welding in the World, vol. 65, no. 12, pp. 2255-2266, December 2021.

J. Xiong, G. Zhang, J. Hu, and L. Wu, “Bead Geometry Prediction for Robotic GMAW-Based Rapid Manufacturing through a Neural Network and a Second-Order Regression Analysis,” Journal of Intelligent Manufacturing, vol. 25, no. 1, pp. 157-163, February 2014.

V. C. Nguyen, T. D. Nguyen, and V. T. Le, “Optimization of Sustainable Milling of SKD11 Steel under Minimum Quantity Lubrication,” Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2022. https://doi.org/10.1177/09544089221110978

G. C. M. Patel and Jagadish, “Experimental Modeling and Optimization of Surface Quality and Thrust Forces in Drilling of High-Strength Al 7075 Alloy: CRITIC and Meta-Heuristic Algorithms,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 43, no. 5, article no. 244, May 2021.

D. T. Sarathchandra, M. J. Davidson, and G. Visvanathan, “Parameters Effect on SS304 Beads Deposited by Wire Arc Additive Manufacturing,” Materials and Manufacturing Processes, vol. 35, no. 7, pp. 852-858, 2020.

D. S. Nagesh and G. L. Datta, “Prediction of Weld Bead Geometry and Penetration in Shielded Metal-Arc Welding Using Artificial Neural Networks,” Journal of Materials Processing Technology, vol. 123, no. 2, pp. 303-312, April 2002.

S. Jindal, R. Chhibber, and N. P. Mehta, “Effect of Welding Parameters on Bead Profile, Microhardness and H2 Content in Submerged Arc Welding of High-Strength Low-Alloy Steel,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol. 228, no. 1, pp. 82-94, January 2014.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.