Investigation of Effects of Process Variables on Weld Bead Characteristics in Surface Coating of 309L Stainless Steel by Wire Arc Additive Manufacturing

DOI:

https://doi.org/10.46604/aiti.2024.14208Keywords:

WAAM, surface coating, 309L stainless steel, optimizationAbstract

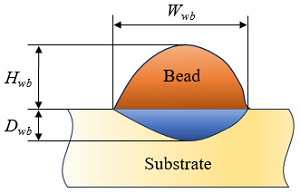

Coating carbon steel surfaces with stainless steel is a crucial technology in various industries to extend the product lifespan. This study focuses on investigating the effects of process parameters on weld bead characteristics in coating SS309L on carbon steel substrates by wire arc additive manufacturing (WAAM) and identifying the optimal parameters. The key parameters are current, travel speed, and voltage, while the weld bead characteristics include height, width, and depth of penetration. Experimental data and analysis of variance (ANOVA) are employed to develop and evaluate predictive models in Minitab software. The results show that the optimal process parameters for coating SS309L on carbon steel substrates by WAAM are voltage = 22 V, current = 132 A, and travel speed = 0.3 m/min, which improve height and width by 56.71% and 25.87%, respectively, while reducing the depth of penetration by 21.74% compared to the worst-case scenario.

References

I. S. Kim, J. S. Lee, and A. Kimura, “Embrittlement of ER309L Stainless Steel Clad by σ-Phase and Neutron Irradiation,” Journal of Nuclear Materials, vol. 329–333, part A, pp. 607-611, 2004.

N. Switzner and Z. Yu, “Austenitic Stainless Steel Cladding Interface Microstructures Evaluated for Petrochemical Applications,” Welding Journal, vol. 98, no. 2, pp. 50S-61S, 2019.

J. W. Oldfield and B. Todd, “Technical and Economic Aspects of Stainless Steels in MSF Desalination Plants,” Desalination, vol. 124, no. 1–3, pp. 75-84, 1999.

S. W. Williams, F. Martina, A. C. Addison, J. Ding, G. Pardal, and P. Colegrove, “Wire + Arc Additive Manufacturing,” Materials Science and Technology, vol. 32, no. 7, pp. 641-647, May 2016.

P. Kazanas, P. Deherkar, P. Almeida, H. Lockett, and S. Williams, “Fabrication of Geometrical Features Using Wire and Arc Additive Manufacture,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol. 226, no. 6, pp. 1042-1051, 2012.

D. Ding, Z. Pan, D. Cuiuri, and H. Li, “Wire-Feed Additive Manufacturing of Metal Components: Technologies, Developments and Future Interests,” The International Journal of Advanced Manufacturing Technology, vol. 81, no. 1-4, pp. 465-481, 2015.

V. T. Le, D. S. Mai, T. K. Doan, and H. Paris, “Wire and Arc Additive Manufacturing of 308L Stainless Steel Components: Optimization of Processing Parameters and Material Properties,” Engineering Science and Technology, an International Journal, vol. 24, no. 4, pp. 1015-1026, 2021.

T. Zhao, H. Liu, L. Li, W. Liu, J. Yue, T. Wang, et al., “An Automatic Compensation Method for Improving Forming Precision of Multi-Layer Multi-Bead Component,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol. 235, no. 8, pp. 1284-1297, 2021.

J. Xiong, G. Zhang, J. Hu, and L. Wu, “Bead Geometry Prediction for Robotic GMAW-Based Rapid Manufacturing Through a Neural Network and a Second-Order Regression Analysis,” Journal of Intelligent Manufacturing, vol. 25, no. 1, pp. 157-163, 2014.

V. T. Le, D. S. Mai, V. T. Dang, D. M. Dinh, T. H. Cao, and V. A. Nguyen, “Optimization of Weld Parameters in Wire and Arc-Based Directed Energy Deposition of High Strength Low Alloy Steels,” Advances in Technology Innovation, vol. 8, no. 1, pp. 01-11, 2023.

S. Suryakumar, K. P. Karunakaran, A. Bernard, U. Chandrasekhar, N. Raghavender, and D. Sharma, “Weld Bead Modeling and Process Optimization in Hybrid Layered Manufacturing,” Computer-Aided Design, vol. 43, no. 4, pp. 331-344, 2011.

A. Kumar and K. Maji, “Selection of Process Parameters for Near-Net Shape Deposition in Wire Arc Additive Manufacturing by Genetic Algorithm,” Journal of Materials Engineering and Performance, vol. 29, no. 5, pp. 3334-3352, 2020.

F. Youheng, W. Guilan, Z. Haiou, and L. Liye, “Optimization of Surface Appearance for Wire and Arc Additive Manufacturing of Bainite Steel,” The International Journal of Advanced Manufacturing Technology, vol. 91, no. 1-4, pp. 301-313, 2017.

D. T. Sarathchandra, M. J. Davidson, and G. Visvanathan, “Parameters Effect on SS304 Beads Deposited by Wire Arc Additive Manufacturing,” Materials and Manufacturing Processes, vol. 35, no. 7, pp. 852-858, 2020.

N. Pravin Kumar, G. Sreedhar, S. Mohan Kumar, B. Girinath, A. Rajesh Kannan, R. Pramod, et al., “Microstructure and Electrochemical Evaluation of ER-308L Weld Overlays on AISI 321 Stainless Steel for Repair Applications,” Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, vol. 238, no. 1, pp. 441-450, 2024.

S. C. Bozeman, O. B. Isgor, and J. D. Tucker, “Effects of Processing Conditions on the Solidification and Heat-Affected Zone of 309L Stainless Steel Claddings on Carbon Steel Using Wire-Directed Energy Deposition,” Surface and Coatings Technology, vol. 444, article no. 128698, 2022.

D. Van Thuc, D. Van Luu, P. H. Cuong, Q. T. Ha, and T. D. Van, “Influence of WAAM Process Parameters on Morphology of Beads When Coating High-Temperature Stainless Steels SS309L on Low Carbon Steel Plates,” International Research Journal of Advanced Engineering and Science, vol. 8, no. 2, pp. 183-186, 2023.

V. T. Le, D. S. Mai, T. K. Doan, and Q. H. Hoang, “Prediction of Welding Bead Geometry for Wire Arc Additive Manufacturing of SS308l Walls Using Response Surface Methodology,” Transport and Communications Science Journal, vol. 71, no. 4, pp. 431-443, 2020.

D. S. Nagesh and G. L. Datta, “Prediction of Weld Bead Geometry and Penetration in Shielded Metal-Arc Welding Using Artificial Neural Networks,” Journal of Materials Processing Technology, vol. 123, no. 2, pp. 303-312, 2002.

S. Jindal, R. Chhibber, and N. P. Mehta, “Effect of Welding Parameters on Bead Profile, Microhardness and H2 Content in Submerged Arc Welding of High-Strength Low-Alloy Steel,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol. 228, no. 1, pp. 82-94, 2014.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Van Thuc Dang, Van Thao Le, Trung Thanh Nguyen, Van Luu Dao

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.