Investigation of a Ball Screw Feed Drive System Based on Dynamic Modeling for Motion Control

Keywords:

Ball nut preload, ball screw drive system, dynamic modelingAbstract

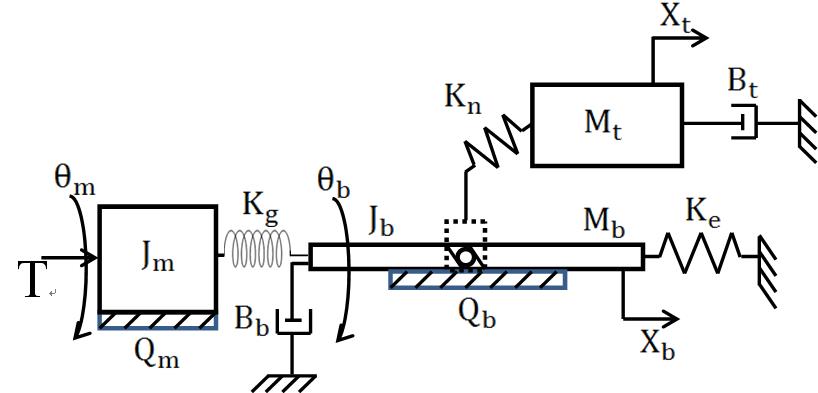

This paper examines the frequency response relationship between the ball screw nut preload, ball screw torsional stiffness variations and table mass effect for a single-axis feed drive system. Identification for the frequency response of an industrial ball screw drive system is very important for the precision motion when the vibration modes of the system are critical for controller design. In this study, there is translation and rotation modes of a ball screw feed drive system when positioning table is actuated by a servo motor. A lumped dynamic model to study the ball nut preload variation and torsional stiffness of the ball screw drive system is derived first. The mathematical modeling and numerical simulation provide the information of peak frequency response as the different levels of ball nut preload, ball screw torsional stiffness and table mass. The trend of increasing preload will indicate the abrupt peak change in frequency response spectrum analysis in some mode shapes. This study provides an approach to investigate the dynamic frequency response of a ball screw drive system, which provides significant information for better control performance when precise motion control is concerned.References

M. S. Tsai, C. L. Yen, and H. T. Yau, “Integration of an empirical mode decomposition algorithm with iterative learning control for high-precision machining,” IEEE/ASME Transaction on Mechatronic, vol. 18, no. 3, pp. 878-886, 2013.

Y. C. Huang, Y. W. Su, and P. C. Chuo, “Iterative learning control bandwidth tuning using the particle swarm optimization technique for high precision motion,” Microsystem Technologies. DOI: 10.1007/s00542-015-2649-6, 2015.

G. H. Feng and Y. L. Pan, “Investigation of ball screw preload variation based on dynamic modeling of a preload adjustable feed-drive system and spectrum analysis of ball-nuts sensed vibration signals,” International Journal of Machine Tools & Manufacture, vol. 52, no. 1, pp. 85-96, 2012.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.