Machine Vision and Deep Learning Based Rubber Gasket Defect Detection

DOI:

https://doi.org/10.46604/aiti.2020.4278Keywords:

traditional rule-based strategy, deep learning, convolutional neural networks (CNN), image recognition, image processing, deep residual learningAbstract

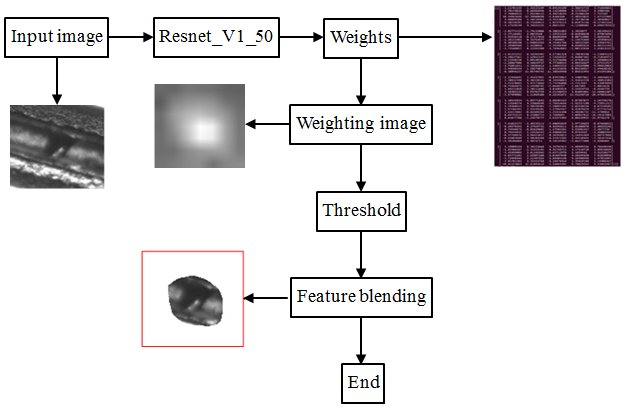

This study develops an automated optical inspection system for silicone rubber gaskets using traditional rule-based and deep learning detection techniques. The specific object of interest is a 5 mm × 10 mm × 5 mm mobile device power supply connector gasket that provides protection against foreign body inclusion and water ingression. The proposed system can detect a total of five characteristic defects introduced during the mold-based manufacture process, which range from 10-100 μm. The deep learning detection strategies in this system employ convolutional neural networks (CNN) developed using the TensorFlow open-source library. Through both high dynamic range image capture and image generation techniques, accuracies of 100% and 97% are achieved for notch and residual glue defect predictions, respectively.

References

A. Cornforth and C. James, “Ultrasonic system for the inspection of rubber gaskets,” NDT International, vol. 13, no. 1, pp. 15-17, February 1980.

C. C. Kuo and Y. T. Siao, “Measuring the solidification time of silicone rubber using optical inspection technology,” Optik-International Journal for Light and Electron Optics, vol. 125, no. 1, pp. 196-199, January 2014.

C. C. Kuo and Y. R. Chen, “Rapid optical inspection of bubbles in the silicone rubber,” International Journal for Light and Electron Optics, vol. 124, no. 13, pp.1480-1485, July 2013.

R. Ciobanu, D. Rizescu, and C. Rizescu Ciprian, “Automatic sorting machine based on vision inspection,” International Journal of Modeling and Optimization, vol. 7, no. 5, pp. 286-290, October 2017.

J. A. Marvel, R. Bostelman, and J. Falco, “Multi-robot assembly strategies and metrics,” ACM Computing Surveys, vol. 51, no. 1, pp. 1-32, April 2018.

Y. X. Yang, Y. T. Lou, M. Y. Gao, and G. J. Ma, “An automatic aperture detection system for LED cup based on machine vision,” Multimedia Tools and Applications, vol. 77, no. 18, pp. 23227-23244, September 2018.

C. C. Ho and T. R. Tsai, “Machine-vision-based servo control of a robotic sewing system,” Advanced Science Letters, vol. 9, no. 1, pp. 45-49, April 2012.

C. C. Ho, J. C. Li, and T. H. Kuo, “Multicamera fusion-based leather defects marking system,” Advances in Mechanical Engineering, vol. 5, 347921, January 2013.

C. C. Ho, Y. M. Chen, and T. Y. Chi, “Machine vision-based automatic placement system for solenoid housing,” Key Engineering Materials, vol. 649, pp. 9-13, March 2015.

C. C. Ho, Y. M. Chen, and P. C. Li., “Machine vision based in-process LED chip mounting system,” Measurement and Control, vol. 51, pp. 1-11, July 2018.

C. C. Ho and J. J. Liu, “Development of auto defect inspection system for cell phone silicone rubber gasket,” Proc. Tenth International Symposium on Precision Engineering Measurements and Instrumentation (ISPEMI 2018), SPIE Press, March 2019, pp. 1105303.

Y. J. Cha, W. Choi, and O. Büyüköztürk, “Autonomous structural visual inspection using region‐based deep learning for detecting multiple damage types,” Computer‐Aided Civil and Infrastructure Engineering, vol. 33, no. 9, pp. 731-747, November 2017.

R. Ren, T. Hung, and K.C. Tan, “A generic deep-learning-based approach for automated surface inspection,” IEEE transactions on cybernetics, vol. 48, no. 3, pp. 929-940, March 2018

Y. J. Cha, W. Choi, and O. Büyüköztürk, “Deep learning‐based crack damage detection using convolutional neural networks,” Computer‐Aided Civil and Infrastructure Engineering, vol. 32, no. 5, pp. 361-378, March 2017.

G. S. Babu, P. L. Zhao, and X. L. Li, “Deep convolutional neural network based regression approach for estimation of remaining useful life,” Proc. International Conference on Database Systems for Advanced Applications (DASFAA), March 2017, pp. 214-228.

R. Ren, T. Hung, K.C. Tan, “A generic deep-learning-based approach for automated surface inspection,” IEEE Transactions on Cybernetics, vol. 48, no. 3, pp. 929-940, March 2018.

G. Psuj, “Multi-sensor data integration using deep learning for characterization of defects in steel elements,” Sensors, vol. 18, no. 1, January 2018.

X. C. Yang, H. Li , Y. T. Yu, X. C. Luo, T. Huang, and X. Yang, “Automatic pixel‐level crack detection and measurement using fully convolutional network,” Computer‐Aided Civil and Infrastructure Engineering, vol. 33, no. 12, pp. 1090-1109, December 2018.

T. Wang, Y. Chen, M. Qiao, and H. Snoussi, “A fast and robust convolutional neural network-based defect detection model in product quality control,” The International Journal of Advanced Manufacturing Technology, vol. 94, no. 9, pp. 3465-3471, February 2018.

R. F. Wei and Y. B. Bi, “Research on recognition technology of aluminum profile surface defects based on deep learning,” Materials, vol. 12, no. 10, May 2019.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.