Measurement Accuracy of Ultrasound Viscoelastic Creep Imaging in Measuring the Viscoelastic Properties of Heterogeneous Materials

DOI:

https://doi.org/10.46604/aiti.2022.9592Keywords:

elastography, elasticity, stiffness, stress relaxation, viscoelasticityAbstract

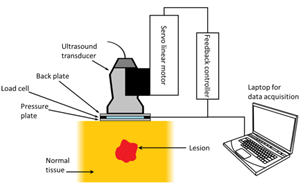

Ultrasound viscoelastic creep imaging (UVCI) is a newly developed technology aiming to measure the viscoelastic properties of materials. The purpose of this study is to investigate the accuracy of UVCI in measuring the viscoelastic properties of heterogeneous materials that mimic pathological lesions and normal tissues. The finite element simulation is used to investigate the measurement accuracy of UVCI on three material models, including a homogeneous material, a single-inclusion phantom, and a three-layer structure. The measurement accuracy for a viscoelastic property is determined by the difference between the simulated measurement result of that viscoelastic property and its true value defined during the simulation process. The results show that UVCI in general cannot accurately measure the true values of the viscoelastic properties of a heterogeneous material, demonstrating the need to further improve the theories and technologies relevant to UVCI to improve its measurement accuracy on tissue-like heterogeneous materials.

References

J. Bamber, et al., “EFSUMB Guidelines and Recommendations on the Clinical Use of Ultrasound Elastography. Part 1: Basic Principles and Technology,” Ultraschall in der Medizin-European Journal of Ultrasound, vol. 34, no. 2, pp. 169-184, April 2013.

T. Shiina, et al., “WFUMB Guidelines and Recommendations for Clinical Use of Ultrasound Elastography. Part 1: Basic Principles and Terminology,” Ultrasound in Medicine and Biology, vol. 41, no. 5, pp. 1126-1147, May 2015.

R. M. Sigrist, et al., “Ultrasound Elastography: Review of Techniques and Clinical Applications,” Theranostics, vol. 7, no. 5, pp. 1303-1329, March 2017.

J. Ophir, et al., “Elastography: A Quantitative Method for Imaging the Elasticity of Biological Tissues,” Ultrasonic Imaging, vol. 13, no. 2, pp. 111-134, April 1991.

A. Diker, et al., “A Novel Application Based on Spectrogram and Convolutional Neural Network for ECG Classification,” 1st International Informatics and Software Engineering Conference, pp. 1-6, November 2019.

J. Bercoff, et al., “Supersonic Shear Imaging: A New Technique for Soft Tissue Elasticity Mapping,” IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, vol. 51, no. 4, pp. 396-409, August 2004.

L. Castera, et al., “Non-Invasive Evaluation of Liver Fibrosis Using Transient Elastography,” Journal of Hepatology, vol. 48, no. 5, pp. 835-847, May 2008.

M. Friedrich-Rust, et al., “Performance of Transient Elastography for the Staging of Liver Fibrosis: A Meta-Analysis,” Gastroenterology, vol. 134, no. 4, pp. 960-974, April 2008.

M. L. Palmeri, et al., “Acoustic Radiation Force-Based Elasticity Imaging Methods,” Interface Focus, vol. 1, no. 4, pp. 553-564, June 2011.

P. N. Wells, et al., “Medical Ultrasound: Imaging of Soft Tissue Strain and Elasticity,” Journal of the Royal Society Interface, vol. 8, no. 64, pp. 1521-1549, June 2011.

R. Masuzaki, et al., “Assessing Liver Tumor Stiffness by Transient Elastography,” Hepatology International, vol. 1, no. 3, pp. 394-397, July 2007.

J. R. Doherty, et al., “Acoustic Radiation Force Elasticity Imaging in Diagnostic Ultrasound,” IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, vol. 60, no. 4, pp. 685-701, March 2013.

J. E. Brandenburg, et al., “Ultrasound Elastography: The New Frontier in Direct Measurement of Muscle Stiffness,” Archives of Physical Medicine and Rehabilitation, vol. 95, no. 11, pp. 2207-2219, November 2014.

C. Y. Lin, et al., “Effects of Loading and Boundary Conditions on the Performance of Ultrasound Compressional Viscoelastography: A Computational Simulation Study to Guide Experimental Design,” Materials, vol. 14, no. 10, Article no. 2590, May 2021.

C. Y. Lin, et al., “Investigating the Accuracy of Ultrasound Viscoelastic Creep Imaging for Measuring the Viscoelastic Properties of a Single-Inclusion Phantom,” International Journal of Mechanical Sciences, vol. 199, Article no. 106409, June 2021.

C. X. Deng, et al., “Ultrasound Imaging Techniques for Spatiotemporal Characterization of Composition, Microstructure, and Mechanical Properties in Tissue Engineering,” Tissue Engineering Part B: Reviews, vol. 22, no. 4, pp. 311-321, February 2016.

D. Huang, et al., “Viscoelasticity in Natural Tissues and Engineered Scaffolds for Tissue Reconstruction,” Acta Biomaterialia, vol. 97, no. 1, pp. 74-92, October 2019.

C. Y. Lin, “Alternative Form of Standard Linear Solid Model for Characterizing Stress Relaxation and Creep: Including a Novel Parameter for Quantifying the Ratio of Fluids to Solids of a Viscoelastic Solid,” Frontiers in Materials, vol. 7, no. 11, Article no. 11, February 2020.

C. Y. Lin, et al., “Quantitative Evaluation of the Viscoelastic Properties of the Ankle Joint Complex in Patients Suffering from Ankle Sprain by the Anterior Drawer Test,” Knee Surgery, Sports Traumatology, Arthroscopy, vol. 21, no. 6, pp. 1396-1403, March 2013.

I. Sack, et al., “Structure-Sensitive Elastography: On the Viscoelastic Powerlaw Behavior of in Vivo Human Tissue in Health and Disease,” Soft Matter, vol. 9, no. 24, pp. 5672-5680, May 2013.

A. Nabavizadeh, et al., “Automated Compression Device for Viscoelasticity Imaging,” IEEE Transactions on Biomedical Engineering, vol. 64, no. 7, pp. 1535-1546, September 2016.

M. Bayat, et al., “Automated in Vivo Sub-Hertz Analysis of Viscoelasticity (SAVE) for Evaluation of Breast Lesions,” IEEE Transactions on Biomedical Engineering, vol. 65, no. 10, pp. 2237-2247, December 2017.

A. Nabavizadeh, et al., “Viscoelastic Biomarker for Differentiation of Benign and Malignant Breast Lesion in Ultra-Low Frequency Range,” Scientific Reports, vol. 9, no. 1, pp. 1-12, April 2019.

M. Bayat, et al., “Multi-Parameter Sub-Hertz Analysis of Viscoelasticity with a Quality Metric for Differentiation of Breast Masses,” Ultrasound in Medicine and Biology, vol. 46, no. 12, pp. 3393-3403, December 2020.

D. Sheet, “Pseudo B-Mode Ultrasound Image Simulator,” https://www.mathworks.com/matlabcentral/fileexchange/34199-pseudo-b-mode-ultrasound-image-simulator, February 24, 2022.

J. C. Bamber, et al., “Ultrasonic B-Scanning: A Computer Simulation,” Physics in Medicine and Biology, vol. 25, no. 3, Article no. 463, May 1980.

Y. Yu, et al., “Speckle Reducing Anisotropic Diffusion,” IEEE Transactions on Image Processing, vol. 11, no. 11, pp. 1260-1270, December 2002.

M. R. Selzo, et al., “On the Quantitative Potential of Viscoelastic Response (VisR) Ultrasound Using the One-Dimensional Mass-Spring-Damper Model,” IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, vol. 63, no. 9, pp. 1276-1287, March 2016.

M. M. Hossain, et al., “Electronic Point Spread Function Rotation Using a Three-Row Transducer for ARFI-Based Elastic Anisotropy Assessment: in Silico and Experimental Demonstration,” IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, vol. 68, no. 3, pp. 632-646, August 2020.

M. Toğaçar, et al., “Tumor Type Detection in Brain MR Images of the Deep Model Developed Using Hypercolumn Technique, Attention Modules, and Residual Blocks,” Medical and Biological Engineering and Computing, vol. 59, no. 1, pp. 57-70, November 2021.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.