Billet Size Optimization for Hot Forging of AISI 1045 Medium Carbon Steel Using Zener-Hollomon and Cingara-McQueen Model

DOI:

https://doi.org/10.46604/ijeti.2024.13302Keywords:

hot forging, compressive tests, Zener-Hollomon, Cingara-McQueen, AISI 1045 carbon steelAbstract

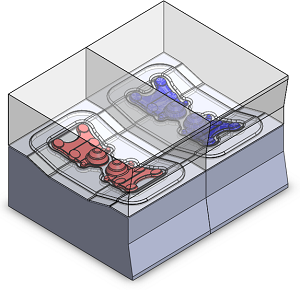

This study investigates the effects of initial billet size variations on material flow behavior in hot forging processes, aiming to optimize the forging process using validated predictive models. Material and high-temperature compressive tests inform mathematical models, while simulations are conducted via the finite element method (FEM). Results align with the Zener-Hollomon and Cingara-McQueen approaches. The Arrhenius model predicts AISI 1045 steel flow stress with an R2 of 0.968 and an average absolute relative error (AARE) of 7.079%. The Cingara-McQueen equation achieves an R2 of 0.997 and an AARE of 2.960%. Reducing billets size from 260 mm to 230 mm decreases the material usage by up to 11.5%, while maintaining workpiece integrity. Experimental and simulated loads exhibit an AARE of about 2.69%, thereby indicating potential cost and efficiency improvements in hot forging processes.

References

T. Altan, G. Ngaile, and G. Shen, Cold and Hot Forging: Fundamentals and Applications, Materials Park, OH: ASM International, 2005.

N. S. Al-Arifi, A. S. Zamani, and J. Khan, “Billet Optimization for Steering Knuckle Using Taguchi Methodology,” International Journal of Computer Theory and Engineering, vol. 3, no. 4, pp. 552-556, August 2011.

P. Soranansri, T. Rojhirunsakool, N. Nithipratheep, C. Ngaouwnthong, K. Boonpradit, C. Treevisootand, et al., “Hot Forging Process Design and Initial Billet Size Optimization for Manufacturing of the Talar Body Prosthesis by Finite Element Modeling,” Applied Science and Engineering Progress, vol. 15, no. 1, article no. 3936, January-March 2022.

N. Siripath, S. Suranuntchai, and S. Sucharitpwatskul, “Cylindrical Billet Size Optimization for Hot Closed-Die Forging of the Upper Ball Joint,” Key Engineering Materials, vol. 946, pp. 9-14, May 2023.

S. S. Satheesh Kumar, T. Raghu, P. P. Bhattacharjee, G. Appa Rao, and U. Borah, “Constitutive Modeling for Predicting Peak Stress Characteristics during Hot Deformation of Hot Isostatically Processed Nickel-Base Superalloy,” Journal of Materials Science, vol. 50, no. 19, pp. 6444-6456, October 2015.

S. A. Kareem, J. U. Anaele, E. O. Aikulola, O. F. Olanrewaju, B. O. Omiyale, M. O. Bodunrin, et al., “Hot Deformation Behaviour, Constitutive Model Description, and Processing Map Analysis of Superalloys: An Overview of Nascent Developments,” Journal of Materials Research and Technology, vol. 26, pp. 8624-8669, September-October 2023.

H. Zhu and H. Ou, “Constitutive Modelling of Hot Deformation Behaviour of Metallic Materials,” Materials Science and Engineering: A, vol. 832, article no. 142473, January 2022.

G. Ge, L. Zhang, J. Xin, J. Lin, M. Aindow, and L. Zhang, “Constitutive Modeling of High Temperature Flow Behavior in a Ti-45Al-8Nb-2Cr-2Mn-0.2Y Alloy,” Scientific Reports, vol. 8, article no. 5453, 2018.

N. Siripath, S. Suranuntchai, and S. Sucharitpwatskul, “Comparative Study on Material Models for BS 080M46 Medium Carbon Steel,” Engineering & Applied Science Research, vol. 51, no. 1, pp. 22-33, January-February 2024.

J. Zhang, H. Di, X. Wang, Y. Cao, J. Zhang, and T. Ma, “Constitutive Analysis of the Hot Deformation Behavior of Fe–23Mn–2Al–0.2C Twinning Induced Plasticity Steel in Consideration of Strain,” Materials & Design, vol. 44, pp. 354-364, February 2013.

Z. S. Motlagh, B. Tolaminejad, and A. Momeni, “Prediction of Hot Deformation Flow Curves of 1.4542 Stainless Steel,” Metals and Materials International, vol. 27, no. 8, pp. 2512-2529, August 2021.

N. Jantepa and S. Suranuntchai, “Investigation of Hot Deformation Behavior of SNCM8 Alloy Steel,” World Journal of Mechanics, vol. 11, no. 03, pp. 17-33, March 2021.

G. Wei, X. Peng, A. Hadadzadeh, Y. Mahmoodkhani, W. Xie, Y. Yang, et al., “Constitutive Modeling of Mg–9Li–3Al–2Sr–2Y at Elevated Temperatures,” Mechanics of Materials, vol. 89, pp. 241-253, October 2015.

A. Sanrutsadakorn, V. Uthaisangsuk, and S. Suranuntchai, “Determination of Initiation of Dynamic Recrystallization in AISI 4340 Steel,” Advanced Materials Research, vol. 893, pp. 381-386, February 2014.

I. Schindler, P. Opěla, P. Kawulok, J. Sojka, K. Konečná, S. Rusz, et al., “Hot Deformation Behaviour of Mn–Cr–Mo Low-Alloy Steel in Various Phase Regions,” Metals, vol. 10, no. 9, article no. 1255, September 2020.

R. B. Prajapati, D. B. Patel, and T. M. Patel, “A Review on Experimental Investigation of GMAW for AISI 1045 by Using Taguchi Method,” International Journal for Scientific Research & Development, vol. 1, no. 8, pp. 1679-1682, 2013.

P. Jedrasiak, H. Shercliff, S. Mishra, C. S. Daniel, and J. Q. da Fonseca, “Finite Element Modeling of Hot Compression Testing of Titanium Alloys,” Journal of Materials Engineering and Performance, vol. 31, no. 9, pp. 7160-7175, September 2022.

A. Sanrutsadakorn, V. Uthaisangsuk, S. Suranuntchai, and B. Thossatheppitak, “Constitutive Modeling of Flow Behaviour of AISI 4340 Steel Under Hot Working Conditions,” Applied Mechanics and Materials, vol. 249-250, pp. 863-869, December 2012.

N. Siripath, S. Suranuntchai, and S. Sucharitpwatskul, “Finite Element Modeling of Upper Ball Joint in a Two-Step Hot Forging Process,” Key Engineering Materials, vol. 934, pp. 95-102, November 2022.

A. Hajari, M. Morakabati, S. M. Abbasi, and H. Badri, “Constitutive Modeling for High-Temperature Flow Behavior of Ti-6242S Alloy,” Materials Science and Engineering: A, vol. 681, pp. 103-113, January 2017.

M. S. Ghazani and B. Eghbali, “Modeling the Flow Behavior of AISI 321 Austenitic Stainless Steel Using a Simple Combined Phenomenological Method,” Mechanics of Materials, vol. 137, article no. 103108, October 2019.

N. Haghdadi, A. Zarei-Hanzaki, and H. R. Abedi, “The Flow Behavior Modeling of Cast A356 Aluminum Alloy at Elevated Temperatures considering the Effect of Strain,” Materials Science and Engineering: A, vol. 535, pp. 252-257, February 2012.

L. Wang, F. Liu, Q. Zuo, and C. F. Chen, “Prediction of Flow Stress for N08028 Alloy under Hot Working Conditions,” Materials & Design, vol. 47, pp. 737-745, May 2013.

J. Porntadawit, V. Uthaisangsuk, and P. Choungthong, “Modeling of Flow Behavior of Ti–6Al–4V Alloy at Elevated Temperatures,” Materials Science and Engineering: A, vol. 599, pp. 212-222, April 2014.

K. B. Kumar, K. K. Saxena, S. R. Dey, V. Pancholi, and A. Bhattacharjee, “Peak Stress Studies of Hot Compressed TiHy 600 Alloy,” Materials Today: Proceedings, vol. 4, no. 8, pp. 7365-7374, 2017.

G. L. Wu, Y. J. Zhang, and S. W. Wu, “Characterization of Hot Deformation Behaviour of Nb-Ti Microalloyed High-Strength Steel,” Journal of the Southern African Institute of Mining and Metallurgy, vol. 119, no. 5, pp. 503-508, May 2019.

N. Jantepa and S. Suranuntchai, “Finite Element Simulation of Ball Joint under Hot Forging Process,” Journal of Physics: Conference Series, vol. 1510, article no. 012013, 2020.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Naiyanut Jantepa, Nattarawee Siripath, Surasak Suranuntchai

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)