Analysis of Strength Parameters of Polymer–Glass Composites Modified with Rubber Recyclate Through Bending Tests

DOI:

https://doi.org/10.46604/ijeti.2024.13319Keywords:

epoxy–glass composites, rubber recyclate, statistical analysis, bending testAbstract

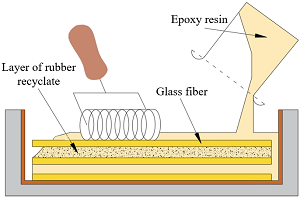

The study aims to analyze the strength properties obtained from three-point bending tests of epoxy-glass composite samples modified by adding rubber recyclate. A pure epoxy-glass composite is used as a comparative variant. The tested materials, which varies in the percentage of rubber recyclate and distribution, are cut through waterjet cutting to minimize the influence of temperature. The results undergo statistical analysis, and the microstructures are examined using scanning electron microscopy. The decreasing bending strength of the composites is observed, as the content of rubber recyclate in the material increased. However, adding rubber recyclate directly into the resin subtly decreases in bending strength compared to adding in the layers between the glass mat layers. Composites with rubber recyclate exhibits lower deflection under load compared to pure composites. The most favorable bending test parameters are obtained for the material containing 5% rubber recyclate distributed in three layers.

References

B. Abdel-Magid, S. Ziaee, K. Gass, and M. Schneider, “The Combined Effects of Load, Moisture and Temperature on the Properties of E-Glass/Epoxy Composites,” Composite Structures, vol. 71, no. 3-4, pp. 320-326, December 2005.

T. Ely and M. Kumosa, “The Stress Corrosion Experiments on an E-Glass/Epoxy Unidirectional Composite,” Journal of Composite Materials, vol. 34, no. 10, pp. 841-878, May 2000.

E. de Bilbao, D. Soulat, G. Hivet, J. Launay, and A. Gasser, “Bending Test of Composite Reinforcements,” International Journal of Material Forming, vol. 1, no. 1 (supplement), pp. 835-838, April 2008.

M. Bocian and K. Jamroziak, “Osłony Balistyczne Z Materiałów Kompozytowych Na Osnowie Polimerowej,” Czasopismo Techniczne. Mechanika, vol. 103, no. 6-M, pp. 53-56, 2006. (In Polski)

M. Barcikowski and K. Rybkowska, “Mode II Fracture Characterization of Toughened Epoxy Resin Composites,” International Journal of Fracture, vol. 234, no. 1-2, pp. 223-233, April 2022.

A. Khodadadi, G. Liaghat, A. R. Bahramian, H. Ahmadi, Y. Anani, S. Asemani, et al., “High Velocity Impact Behavior of Kevlar/Rubber and Kevlar/Epoxy Composites: A Comparative Study,” Composite Structures, vol. 216, pp. 159-167, May 2019.

H. Adin and M. Ş. Adin, “Effect of Particles on Tensile and Bending Properties of Jute Epoxy Composites,” Materials Testing, vol. 64, no. 3, pp. 401-411, 2022.

H. Chandekar, V. Chaudhari, and S. Waigaonkar, “A Review of Jute Fiber Reinforced Polymer Composites,” Materials Today: Proceedings, vol. 26, part. 2, pp. 2079-2082, 2020.

X. Wang, X. L. Shi, Q. K. Meng, Y. C. Hu, and L. H. Wang, “Bending Behaviors of Three Grid Sandwich Structures with Wood Facing and Jute Fabrics/Epoxy Composites Cores,” Composite Structures, vol. 252, article no. 112666, November 2020.

J. Tarrio-Saavedra, J. López-Beceiro, S. Naya, and R. Artiaga, “Effect of Silica Content on Thermal Stability of Fumed Silica/Epoxy Composites,” Polymer Degradation and Stability, vol. 93, no. 12, pp. 2133-2137, December 2008.

A. A. Nayeeif, Z. K. Hamdan, Z. W. Metteb, F. A. Abdulla, and N. A. Jebur, “Natural Filler Based Composite Materials,” Archives of Materials Science and Engineering, vol. 116, no. 1, pp. 5-13, July 2022.

N. S. N. Arman, R. S. Chen, and S. Ahmad, “Review of State-of-the-Art Studies on the Water Absorption Capacity of Agricultural Fiber-Reinforced Polymer Composites for Sustainable Construction,” Construction and Building Materials, vol. 302, article no. 124174, October 2021.

K. K. Veedu, S. Mohan, S. B. Somappa, and N. K. Gopalan, “Eco-Friendly Anticorrosive Epoxy Coating from Ixora Leaf Extract: A Promising Solution for Steel Protection in Marine Environment,” Journal of Cleaner Production, vol. 340, article no. 130750, March 2022.

B. S. Butola, A. Majumdar, A. Jain, and G. Kaur, “Multilayered Flexible Uni-Polymer and Hybrid Composites for Ballistic Applications,” Fibers and Polymers, vol. 18, no. 4, pp. 786-794, April 2017.

S. E. Moussavi-Torshizi, S. Dariushi, M. Sadighi, and P. Safarpour, “A Study on Tensile Properties of a Novel Fiber/Metal Laminates,” Materials Science and Engineering: A, vol. 527, no. 18-19, pp. 4920-4925, July 2010.

M. Shah, P. Mondal, A. K. Nayak, and A. Bordoloi, “Advanced Titania Composites for Efficient CO2 Reforming with Methane: Statistical Method vs. Experiment,” Journal of CO2 Utilization, vol. 39, article no. 101160, July 2020.

S. C. Shi, T. H. Chen, and P. K. Mandal, “Enhancing the Mechanical and Tribological Properties of Cellulose Nanocomposites with Aluminum Nanoadditives,” Polymers, vol. 12, no. 6, article no. 1246, June 2020.

V. A. Chatterjee, S. K. Verma, D. Bhattacharjee, I. Biswas, and S. Neogi, “Enhancement of Energy Absorption by Incorporation of Shear Thickening Fluids in 3D-Mat Sandwich Composite Panels upon Ballistic Impact,” Composite Structures, vol. 225, article no. 111148, October 2019.

A. Bala and S. Gupta, “Thermal Resistivity, Sound Absorption and Vibration Damping of Concrete Composite Doped with Waste Tire Rubber: A Review,” Construction and Building Materials, vol. 299, article no. 123939, September 2021.

F. C. Cabrera, “Eco-Friendly Polymer Composites: A Review of Suitable Methods for Waste Management,” Polymer Composites, vol. 42, no. 6, pp. 2653-2677, June 2021.

N. Candau, N. León Albiter, and M. Maspoch Rulduà, “High Added Value Rubber Composites and Thermoplastic Elastomers as Strategies to Recycle Wastes Rubber,” 11th EEIGM International Conference on Advanced Materials Research, p. 1, June 2022.

A. Fazli and D. Rodrigue, “Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers,” Materials, vol. 13, no. 3, article no. 782, February 2020.

M. Choudhary, T. Singh, M. Dwivedi, and A. Patnaik, “Waste Marble Dust-Filled Glass Fiber-Reinforced Polymer Composite Part I: Physical, Thermomechanical, and Erosive Wear Properties,” Polymer Composites, vol. 40, no. 10, pp. 4113-4124, October 2019.

M. Rani, P. Choudhary, V. Krishnan, and S. Zafar, “A Review on Recycling and Reuse Methods for Carbon Fiber/Glass Fiber Composites Waste from Wind Turbine Blades,” Composites Part B: Engineering, vol. 215, article no. 108768, June 2021.

A. Abdelmonem, M. S. El-Feky, E. S. A. R. Nasr, and M. Kohail, “Performance of High Strength Concrete Containing Recycled Rubber,” Construction and Building Materials, vol. 227, article no. 116660, December 2019.

M. Al-Shablle, M. Al-Waily, and E. K. Njim, “Analytical Evaluation of the Influence of Adding Rubber Layers on Free Vibration of Sandwich Structure with Presence of Nano-Reinforced Composite Skins,” Archives of Materials Science and Engineering, vol. 116, no. 2, pp. 57-70, August 2022.

B. Marques, J. Antonio, J. Almeida, A. Tadeu, J. de Brito, S. Dias, et al., “Vibro-Acoustic Behaviour of Polymer-Based Composite Materials Produced with Rice Husk and Recycled Rubber Granules,” Construction and Building Materials, vol. 264, article no, 120221, December 2020.

A. Charchalis, M. Kneć, D. Żuk, and N. Abramczyk, “Use of 3D Optical Techniques in the Analysis of the Effect of Adding Rubber Recyclate to the Matrix on Selected Strength Parameters of Epoxy–Glass Composites,” Acta Mechanica et Automatica, vol. 17, no. 3, pp. 333-346, 2023.

N. Abramczyk, D. Żuk, K. Panasiuk, and T. Dyl, “Influence of the Type of Layered Distribution of Rubber Recyclate as an Additive Modifying the Mechanical Properties of Epoxy-Glass Composites,” Archives of Materials Science and Engineering, vol. 118, no. 2, pp. 61-66, December 2022.

D. Żuk, N. Abramczyk, and A. Charchalis, “Analysis of the Impact of Rubber Recyclate Addition to the Matrix on the Strength Properties of Epoxy–Glass Composites,” Polymers, vol. 15, no. 16, article no. 3374, August 2023.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Daria Żuk

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)