Analysis of Atomization Performance of Linear Laval Nozzle under Varied Water Pressures Based on VOF and DPM Models

DOI:

https://doi.org/10.46604/ijeti.2024.13615Keywords:

linear laval nozzle, VOF, DPM, water pressure, atomizing performanceAbstract

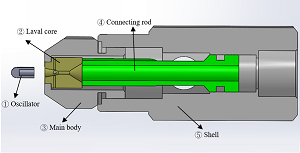

Particulate matter from coal and stone operations is a primary air pollution source. The traditional nozzle requires high-pressure conditions, and the atomization droplets are large and uneven. This paper aims to study a linear Laval nozzle and investigate the impact of water pressure on atomization performance. The volume of fluid (VOF) model and discrete phase model (DPM) of Fluent are used to simulate the internal and external fields of the nozzle and analyze the velocity, droplet size, and atomization angle. The results show that the optimized water pressure parameters are 0.1 MPa with an air pressure of 0.5 MPa. Droplets in the middle are smaller, while those on the sides are larger. Compared to traditional nozzles, the water pressure is reduced by over 90%, and the Sauter mean diameter (SMD) decreases by over 50%. Moreover, the theoretical spray angle increases by approximately 150%.

References

C. Yang, B. Chen, W. Jiang, D. Gao, and G. Jin, “Analysis and Experiment on Atomizing Characteristics of Supersonic Nozzle Based on Laval Effect,” Transactions of the Chinese Society of Agricultural Engineering, vol. 32, no. 19, pp. 57-64, October 2016.

S. Tang, M. D. Ibrahim, A. R. H. Rigit, W. Zhang, and C. Wei, “A Systematic Review of Dust Suppression Methods by Experiment Based on Intelligent Technology in the Coal Mines,” Journal of Electrical Systems, vol. 20, no. 3, pp. 882-893, 2024.

F. Anlimah, V. Gopaldasani, C. MacPhail, and B. Davies, “A Systematic Review of the Effectiveness of Dust Control Measures Adopted to Reduce Workplace Exposure,” Environ Sci Pollut Res, vol. 30, no. 19, pp. 54407-54428, April 2023.

Z. Liu, W. Nie, H. Peng, S. Yang, D. Chen, and Q. Liu, “The Effects of the Spraying Pressure and Nozzle Orifice Diameter on the Atomizing Rules and Dust Suppression Performances of an External Spraying System in a Fully-Mechanized Excavation Face,” Powder Technology, vol. 350, pp. 62-80, May 2019.

C. Xu, W. Nie, Z. Liu, H. Peng, S. Yang, and Q. Liu, “Multi-Factor Numerical Simulation Study on Spray Dust Suppression Device in Coal Mining Process,” Energy, vol. 182, pp. 544–558, Sep. 2019.

C. Xu, W. Nie, S. Yang, H. Peng, Z. Liu, Q. Ma, et al., “Numerical Simulation of the Multi-Index Orthogonal Experiments on the Spray Dust-Settling Devices,” Powder Technology, vol. 371, pp. 217-230, June 2020.

S. Arya, J. Sottile, and T. Novak, “Numerical Modeling of a Flooded-Bed Dust Scrubber Integrated into a Longwall Shearer,” Mining, Metallurgy & Exploration, vol. 37, no. 4, pp. 1105-1119, August 2020.

Y. Shi, P. Wang, R. Liu, X. Tan, and W. Zhang, “Numerical Simulation and Engineering Application of Coalbed Water Injection,” Mathematical Problems in Engineering, vol. 2019, article no. 6309160, 2019.

P. Wang, H. Han, R. Liu, R. Gao, and G. Wu, “Effect of Outlet Diameter on Atomization Characteristics and Dust Reduction Performance of X-Swirl Pressure Nozzle,” Process Safety and Environmental Protection, vol. 137, pp. 340-351, May 2020.

T. Zhang, D. Jing, S. Ge, J. Wang, X. Chen, and S. Ren, “Dust Removal Characteristics of a Supersonic Antigravity Siphon Atomization Nozzle,” Advances in Mechanical Engineering, vol. 12, no. 12, article no. 1687814020977689, 2020.

T. Zhang, D. Jing, S. Ge, J. Wang, and X. Chen, “Supersonic Antigravity Aerodynamic Atomization Dusting Nozzle Based on the Laval Nozzle and Probe Jet,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 42, no. 6, article no. 335, June 2020.

O. Dumitrescu, B. Gherman, and T. Tipa, “Development of a Laval Nozzle for a Cold Gas Propulsion System,” IOP Conference Series: Materials Science and Engineering, vol. 400, no. 4, article no. 042016, 2018.

Y. Liu, J. Zhang, J. Wei, and X. Liu, “Optimum Structure of a Laval Nozzle for an Abrasive Air Jet Based on Nozzle Pressure Ratio,” Powder Technology, vol. 364, pp. 343-362, March 2020.

G. Lai and W. Sheng, “Supersonic Reacting Jet Flows from a Three-Dimensional Divergent Conical Nozzle,” SIAM Journal on Mathematical Analysis, vol. 55, no. 5, pp. 5260-5317, 2023.

O. Durif, “Design of de Laval Nozzles for Gas-Phase Molecular Studies in Uniform Supersonic Flow,” Physics of Fluids, vol. 34, no. 1, article no. 013605, January 2022.

O. O. Mil’man, A. S. Goldin, B. A. Shifrin, V. B. Perov, L. N. Serezhkin, A. V. Ptakhin, et al., “Experimental Investigation into Performance of Laval Nozzles for Reaction Turbines,” Thermal Engineering, vol. 70, no. 12, pp. 1083-1101, December 2023.

Q. Xu and J. Xie, “Numerical Simulation of the Effect of Different Numbers of Inlet Nozzles on Vortex Tubes,” Processes, vol. 9, no. 9, article no. 1531, September 2021.

Y. Xu, Q. Li, B. Li, and Z. Guan, “Numerical Simulation Study of Hydraulic Fracturing Nozzle Erosion in Deep Well,” Frontiers in Physics, vol. 10, article no. 947094, 2022.

H. Ou, L. Su, Y. Shi, and S. Ruan, “Investigation on High-Viscosity Chemical Waste Liquid Atomizer Based on VOF-DPM,” Energies, vol. 16, no. 7, article no. 3109, April 2023.

I. A. Fetuga, O. T. Olakoyejo, S. M. Abolarin, A. O. Adelaja, S. O. Ologunoba, O. Oluwatusin, et al., “Eulerian–Lagrangian Fluid Dynamics Study on the Effects of Inlet Radial Angle on the Performance and Flow Pattern of Multi-Inlet Cyclone Separator,” Alexandria Engineering Journal, vol. 78, pp. 453-468, September 2023.

Q. Zeng, S. Zhu, Z. Li, and X. Guo, “Self-Adaptive Triangular Mesh Generation Framework for Free-Form Single-Layer Reticulated Shells Based on Virtual Interaction Forces,” Automation in Construction, vol. 148, article no. 104750, April 2023.

T. Zhao, C. Chen, X. Liu, and J. Hao, “Effect of Gas Mach Number on the Flow Field of Close-Coupled Gas Atomization, Particle Size and Cooling Rate of As-Atomized Powder: Simulation and Experiment,” Advanced Powder Technology, vol. 34, no. 5, article no. 104007, May 2023.

Y. Wang, Z. Jiang, F. Zhang, Y. Lu, and Y. Bao, “Study on Dust Diffusion Characteristics of Continuous Dust Sources and Spray Dust Control Technology in Fully Mechanized Working Face,” Powder Technology, vol. 396, part B, pp. 718-730, January 2022.

L. Li, A. Chen, T. Deng, J. Zeng, F. Xu, S. Yan, et al., “A Simple Optical Aerosol Sensing Method of Sauter Mean Diameter for Particulate Matter Monitoring,” Biosensors, vol. 12, no. 7, article no. 436, July 2022.

Z. Feng, C. Tang, Y. Yin, P. Zhang, and Z. Huang, “Time-Resolved Droplet Size and Velocity Distributions in a Dilute Region of a High-Pressure Pulsed Diesel Spray,” International Journal of Heat and Mass Transfer, vol. 133, pp. 745-755, April 2019.

N. S. Atiqah, A. I. M. Shaiful, M. R. Rahim, and N. A. Shuaib, “Bio-Kerosene from Palm Based Fuel: Study of Spray Droplet Size,” AIP Conference Proceedings, vol. 2339, no. 1, article no. 020226, May 2021.

B. Siavash Amoli, S. S. Mousavi Ajarostaghi, K. Sedighi, and M. Aghajani Delavar, “Evaporative Pre-Cooling of a Condenser Airflow: Investigation of Nozzle Cone Angle, Spray Inclination Angle and Nozzle Location,” Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, vol. 44, no. 3, pp. 8040-8059, 2022.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Shanshan Tang, Mohd Danial Ibrahim, Andrew Ragai Henry Rigit, Wei Zhang, Chaokun Wei

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)