Mechanical Properties of Dynamically Vulcanized Thermoplastic Polyurethane (TPU)/Polybutadiene Rubber (BR) Blends

Keywords:

dynamic vulcanization, blend, TPU, BRAbstract

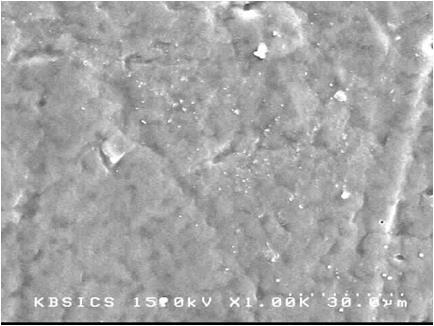

To obtain thermoplastic polyurethane (TPU) with low hardness, dynamically vulcanized TPU/polybutadiene rubber(BR)(70/30) blends were prepared. The effect of dicumyl peroxide (DCP) content and stabilizers on the tensile strength and elongation at break of the dynamically vulcanized blends was examined. The tensile strength and elongation at break of the dynamically vulcanized blends decrease with increasing content of DCP. The addition of optimal content of stabilizer leads to the improvement of tensile strength and elongation at break of the blends. Also, the effect of sulfur cure systems and accelerators on the tensile strength and elongation of the blends was investigated. The tensile strength and elongation at break of all the dynamically vulcanized TPU/BR (70/30) blends using 1-step processing are not higher than those of simple TPU/BR (70/30) blends. However, the tensile strength and elongation of the dynamically vulcanized blends prepared at 8 min (mixing time) using 2-step processing are higher than those of the simple blends.References

E. G. Bajsic,I.Smit, and M. Leskovac, “Blends of thermoplastic polyurethane and polypropylene. I. Mechanical and phase behavior,” Journal of Applied Polymer Science, vol. 104, pp. 3980-3985, 2007.

S. Pichaiyut, C. Nakason, C. Kummerlowe, and N. Vennemann, “Thermoplastic elastomer based on epoxidized natural rubber/thermoplastic polyurethane blends: influence of blending technique,” Polymers Advanced Technologies, vol. 23, pp. 1011-1019, 2012.

F. S. Liao, A. C. Su, and T. C. J. Hsu, “Damping behaviour of dynamically cured butyl rubber/polypropylene blends,” Polymer, vol. 35, pp. 2579-2586, 1994.

P. Martin, C. Maquet, R. Legras, C. Bailly, L. Leemans, M. van Gurp, and M. van Duin, “Conjugated effects of the compatibilization and the dynamic vulcanization on the phase inversion behavior in poly(butylene terephthalate)/epoxide containing rubber reactive polymer blends,” Polymer, vol. 45, pp. 5111-5125, 2004.

Z. J. Wang, X. F. Zhang, and Y. X. Zhang, “Impact properties of dynamically vulcanized nylon/styrene-acrylonitrile copolymer/nitrile rubber blends,” Polymer Testing, vol. 21, pp. 577-582, 2002.

C. Nakason, P. Wannvilai, and A. Kaesaman, “Effect of vulcanization system on properties of thermoplastic vulcanizates based on epoxidized natural rubber/polypropylene blends,” Polymer Testing, vol. 25, pp. 34-41, 2006.

J. T. Yeh and S. C. Lin, “Optimized processing conditions for the preparation of dynamically vulcanized EPDM/PP thermoplastic elastomers containing PP resins of various melt indexes,” Journal of Applied Polymer Science, vol. 114, pp. 2806-2815, 2009.

M. D. Ellul, A. H. Tsou, and W. Hu,”Crosslink densities and phase morphologies in thermoplastic vulcanizates,” Polymer, vol. 45, pp. 3351-3358, 2004.

G. Martin, C. Barres, P. Sonntag, N. Garois, and P. Cassagnau, “Morphology development in thermoplastic vulcanizates (TPV): Dispersion mechanisms of a pre-crosslinked EPDM phase,” European Polymer Journal, vol. 45, pp. 3257-3268, 2009.

C. Nakason, K. Nuansomsri, A. Kaesaman, and S. Kiatkamjornwong, “Dynamic vulcanization of natural rubber/high-density polyethylene blends: effect of compatibilization, blend ratio and curing system,” Polymer Testing, vol. 25, pp. 782-796, 2006.

M. Hernandez, J. Gonzalez, C. Albano, M. Ichazo, and D. Lovera, “Effects of composition and dynamic vulcanization on the rheological properties of PP/NBR blends,” Polymer Bulletin, vol. 50, pp. 205-212, 2003.

P. Potschke, K. Wallheinke, H. Fritsche, and H. Stutz, “Morphology and properties of blends with different thermoplastic

polyurethanes and polyolefines,” Journal of Applied Polymer Science, vol. 64, pp. 749-762, 1997.

E.G. Bajsic,A. Pustak,I.Smit, and M. Leskovac, “Blends of thermoplastic polyurethane and polypropylene. II. Thermal and morphological behavior,” Journal of Applied Polymer Science, vol. 117, pp. 1378-1384, 2010.

Y. Di, M. Kang, Y. Zhao, S. Yan, and X. Wang, “Morphology and mechanical properties of blends of thermoplastic polyurethane and polyolefins,” Journal of Applied Polymer Science, vol. 99, pp. 875-883, 2006.

G. T. Lim, M. H. Ju, D. H. Kim, K. C. Song, and S. U. Kim, “Morphology and properties of PP/PU blends prepared by compositional quenching,” Elastomers and Composites, vol. 36, pp. 177-187, 2001.

H. Y. Mi, M. R. Salick, X. Jing, B. R. Jacques, W. C. Crone, X. F. Peng, and L. S. Turng, “Characterization of thermoplastic polyurethane/polylactic acid (TPU/PLA) tissue engineering scaffolds fabricated by microcellular injection molding,” Materials Science and Engineering C, vol. 33, pp. 4767-4776, 2013.

J. Huang, X. Lu, G. Zhang, and J. Qu, “Study on the rheological, thermal and mechanical properties of thermoplastic polyurethane/poly (butylene terephthalate) blends,” Polymer Testing, vol. 36, pp. 69-74, 2014.

F.Yu and H.X.Huang, “Simultaneously toughening and reinforcing poly(lactic acid)/thermoplastic polyurethane blend via enhancing interfacial adhesion by hydrophobic silica nanoparticles,” Polymer Testing, vol. 45, pp. 107-113, 2015.

E. Oliaei and B. Kaffashi, “Investigation on the properties of poly(L-lactide)/thermoplastic poly(ester urethane)/halloysite nanotube composites prepared based on prediction of halloysite nanotube location by measuring free surface energies,” Polymer, vol. 104, pp. 104-114, 2016.

X. Jing, H. Y. Mi, H. X. Huang, and L. S. Turng, “Shape memory thermoplastic polyurethane (TPU)/poly(ε-caprolactone) (PCL)blends as self-knotting sutures,” Journal of the Mechanical Behavior of Biomedical Materials, vol. 64, pp. 94-103, 2016.

E. Kalkornsurapranee, C. Nakason, C. Kummerlowe, and N. Vennemann, “Development and preparation of high-performance thermoplastic vulcanizates based on blends of natural rubber and thermoplastic polyurethanes,” Journal of Applied Polymer Science, vol. 128, pp. 2358-2367, 2013.

B. Jurkowski, Y. A. Olkhov, B. Jurkowska, and H. Menge, “Comparative TMA and NMR investigation of a structure of carbon-black-free cured butadiene rubber,” Polymer Testing, vol. 21, pp. 597-606, 2002.

I. Suryaa and H. Ismail, “The effect of the addition of alkanolamide on properties of carbon black-filled natural rubber (SMR-L) compounds cured using various curing systems,” Polymer Testing, vol. 50, pp. 276-282, 2016.

Published

How to Cite

Issue

Section

License

Copyright (c) 2016 International Journal of Engineering and Technology Innovation

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)