Numerical and Experimental Study on the Grinding Performance of Ti-Based Super-Alloy

DOI:

https://doi.org/10.46604/ijeti.2021.7199Keywords:

grinding, titanium alloy, grinding force, grinding temperature, finite element simulationAbstract

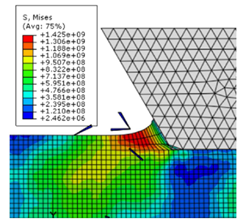

The experiments of the surface grinding of Ti-6Al-4V grade 5 alloy (Ti-64) with a resin-bonded cubic Boron Nitride (cBN) grinding wheel are performed in this research to estimate the influence of cutting parameters named workpiece infeed speed, Depth of Cut (DOC), cooling condition on the grinding force, force ratio, and specific energy. A finite element simulation model of single-grain grinding of Ti-64 is also implemented in order to predict the values of grinding forces and temperature. The experimental results show that an increase of workpiece infeed speed creates higher intensified cutting forces than the DOC. The grinding experiments under wet conditions present slightly lower tangential forces, force ratio, and specific energy than those in dry grinding. The simulation outcomes exhibit that the relative deviation of simulated and experimental forces is in the range of 1-15%. The increase in feed rate considerably reduces grinding temperature, while enhancement of DOC elevates the heat generation in the cutting zone.

References

M. Mukhopadhyay and P. K. Kundu, “Performance Evaluation of Conventional Abrasive Wheels for Grinding Ti-6Al-4V,” IOP Conference Series: Materials Science and Engineering, July 2018, pp. 1-6.

S. Shen, B. Li, and W. Guo, “Surface Integrity in Grinding of C-250 Maraging Steel with Resin-Bonded and Electroplated CBN Grinding Wheels,” International Journal of Advanced Manufacturing Technology, vol. 103, no. 1-4, pp. 1079-1094, March 2019.

Z. Chen, H. Qi, B. Zhao, Y. Zhou, L. Shi, H. N. Li, and W. Ding, “On the Tribology and Grinding Performance of Graphene-Modifed Porous Composite-bonded CBN Wheel,” Ceramics International, vol. 47, no. 3, pp. 3259-3266, February 2021.

Q. Li, K. Ding, W. Lei, J. Chen, Q. He, and Z. Chen, “Investigation on Induction Brazing of Profiled cBN Wheel for Grinding of Ti-6Al-4V,” Chinese Journal of Aeronautics, vol. 34, no. 4, pp. 132-139, July 2020.

A. Naskar, A. Choudhary, and S. Paul, “Wear Mechanism in High-Speed Superabrasive Grinding of Titanium Alloy and Its Effect on Surface Integrity,” Wear, vol. 462-463, pp. 1-13, December 2020.

B. Zhao, W. Ding, Y. Zhou, H. Su, and J. Xu, “Effect of Grain Wear on Material Removal Behaviour during Grinding of Ti-6Al-4V Titanium Alloy with Single Aggregated cBN Grain,” Ceramics International, vol. 45, no. 12, pp. 14842-14850, August 2019.

P. Yadav and D. B. Lee, “Oxidation of Titanium and Ti/ (TiB+TiC) Composite,” Advances in Technology Innovation, vol. 2, no. 4, pp. 130-132, October 2017.

Z. Li, W. Ding, C. Liu, and H. Su, “Prediction of Grinding Temperature of PTMCs Based on the Varied Coefficients of Friction in Conventional-Speed and High-Speed Surface Grinding,” International Journal of Advanced Manufacturing Technology, vol. 90, no. 5-8, pp. 2335-2344, May 2017.

D. Handa, S. Kumar, S. B. T. Surendran, and V. S. Sooraj, “Simulation of Intermittent Grinding for Ti-6Al-4V with Segmented Wheel,” Materials Today: Proceedings, in press.

K. Song, G. Xiao, S. Chen, and S. Li, “Analysis of Thermal-Mechanical Causes of Abrasive Belt Grinding for Titanium Alloy,” The International Journal of Advanced Manufacturing Technology, in press.

H. Yun, L. Shuai, X. Guijian, H. Yi, W. Wenxi, and D. Wentao, “Prediction of Surface Residual Stress on Titanium Alloy Generated by Belt Grinding Using Molecular System Dynamics,” Procedia CIRP, vol. 87, pp. 480-484, 2020.

C. Liu, W. Ding, T. Yu, and C. Yang, “Materials Removal Mechanism in High-Speed Grinding of Particulate Reinforced Titanium Matrix Composites,” Precision Engineering, vol. 51, pp. 68-77, January 2018.

V. Malik, N. K. Sanjeev, and P. Bajakke, “Review on Modelling of Friction Stir Welding Using Finite Element Approach and Significance of Formulations in Simulation,” International Journal of Manufacturing Research, vol. 15, no. 2, pp. 107-135, March 2020.

S. Malkin and C. Guo, Grinding Technology: Theory and Applications of Machining with Abrasives, 2nd ed. New York: Industrial Press, 2008.

H. Zhou, W. Ding, and C. Liu, “Material Removal Mechanism of PTMCs in High-Speed Grinding When Considering Consecutive Action of Two Abrasive Grains,” International Journal of Advanced Manufacturing Technology, vol. 100, no. 1-4, pp. 153-165, January 2019.

D. Fu, W. Ding, Q. Miao, and J. Xu, “Simulation Research on the Grinding Forces and Stresses Distribution in Single-Grain Surface Grinding of Ti-6Al-4V Alloy When Considering the Actual Cutting-Depth Variation,” International Journal of Advanced Manufacturing Technology, vol. 91, no. 9, pp. 3591-3602, August 2017.

S. Paul, A. K. Singh, and A. Ghosh, “Grinding of Ti-6Al-4V Under Small Quantity Cooling Lubrication Environment Using Alumina and MWCNT Nanofluids,” Materials and Manufacturing Processes, vol. 32, no. 6, pp. 608-615, November 2016.

Z. Li, W. Ding, C. Liu, and H. Zhou, “Grinding Performance of TiCp/Ti-6Al-4V Composites with CBN Wheels, Part I: Experimental Investigation and Surface Features,” Procedia CIRP, vol. 77, pp. 525-528, January 2018.

R. L. Virdi, S. S. Chatha, and H. Singh, “Performance Evaluation of Inconel 718 Under Vegetable Oils Based Nanofluids Using Minimum Quantity Lubrication Grinding,” Materials Today: Proceedings, vol. 33, no. 3, pp. 1538-1545, April 2020.

G. Guo, Z. Liu, X. Zheng, and M. Chen, “Investigation on Surface Grinding of Ti-6Al-4V Using Minimum Quantity Lubrication,” Advanced Materials Research, vol. 500, pp. 308-313, April 2012.

W. Kacalak, D. Lipiński, B. Bałasz, Ł. Rypina, K. Tandecka, and F. Szafraniec, “Performance Evaluation of the Grinding Wheel with Aggregates of Grains in Grinding of Ti-6Al-4V Titanium Alloy,” International Journal of Advanced Manufacturing Technology, vol. 94, no. 1-4, pp. 301-314, January 2018.

A. Kundu, M. Mukhopadhyay, S. Mahata, A. Banerjee, B. Mandal, and S. Das, “Grinding Titanium Grade 1 Alloy with an Alumina Wheel Using Soap Water,” Procedia Manufacturing, vol. 20, pp. 338-343, 2018.

N. Qian, W. Ding, and Y. Zhu, “Comparative Investigation on Grindability of K4125 and Inconel 718 Nickel-Based Superalloys,” International Journal of Advanced Manufacturing Technology, vol. 97, no. 5-8, pp. 1649-1661, April 2018.

Y. Zhang, B. Li, J. Yang, and S. Liang, “Modeling and Optimization of Alloy Steel 20CrMnTi Grinding Process Parameters Based on Experiment Investigation,” International Journal of Advanced Manufacturing Technology, vol. 95, no. 5, pp. 1859-1873, March 2018.

X. Wang, T. Yu, X. Sun, Y. Shi, and W. Wang, “Study of 3D Grinding Temperature Field Based on Finite Difference Method: Considering Machining Parameters and Energy Partition,” International Journal of Advanced Manufacturing Technology, vol. 84, no. 5-8, pp. 915-927, May 2016.

Published

How to Cite

Issue

Section

License

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)