Numerical Study of Vortex Flow in a Classifier with Coaxial Tubes

DOI:

https://doi.org/10.46604/ijeti.2022.9568Keywords:

separation efficiency, tube classifier, vortex, velocity fieldAbstract

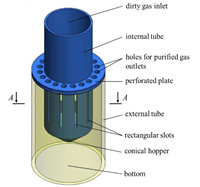

Centrifugal air classifiers are one of the most used separation devices in particle technology. The study aims to obtain a detailed description of the bulk material classification mechanism in the developed centrifugal classifier. The classifier design and the mechanism of the stable vortex structure formation in the inter-tube space of the device are described. Velocities within and between the vortices are studied to identify regions with inverse flows, which serve as transport channels for particles. The computational fluid dynamics modeling results indicate three channels with negative or near-zero axial velocities: between the vortices, near the outer wall of the internal tube, and the inner wall of the external tube. The selectivity of the device decreases when transport channels are disrupted due to flow mixing, which is caused by the height shifting of the vortex centers.

References

K. Riener, et al., “Influence of Particle Size Distribution and Morphology on the Properties of the Powder Feedstock as Well as of AlSi10Mg Parts Produced by Laser Powder Bed Fusion (LPBF),” Additive Manufacturing, vol. 34, Article no. 101286, August 2020.

E. Ortega-Rivas, Unit Operations of Particulate Solids: Theory and Practice, New York: CRC Press, 2017.

V. Zinurov, et al., “Design of High-Efficiency Device for Gas Cleaning from Fine Solid Particles,” 6th International Conference on Industrial Engineering, pp. 378-385, May 2021.

I. N. Madyshev, et al., “Pressure Drop and Particle Collection Efficiency of Multivortex Separator,” IOP Conference Series: Earth and Environmental Science, vol. 988, no. 4, Article no. 042069, February 2022.

H. Rumpf, Particle Technology, London: Chapman and Hall, 1990.

V. E. Zinurov, et al., “Classification of Bulk Material from the Gas Flow in a Device with Coaxially Arranged Pipes,” E3S Web of Conferences, vol. 193, Article no. 01056, October 2020.

V. E. Zinurov, et al., “The Gas Flow Dynamics in a Separator with Coaxially Arranged Pipes,” MATEC Web of Conferences, vol. 329, Article no. 03035, November 2020.

T. Yoshida, et al., “Meta-Model of Vertical Air Classification: A Unified Understanding of Different Separation Curve Models,” Powder Technology, vol. 383, p. 522-535, May 2021.

P. Fu, et al., “Fine Particle Sorting and Classification in the Cyclonic Centrifugal Field,” Separation and Purification Technology, vol. 158, pp. 357-366, January 2016.

H. Li, et al., “Operational Performance Characteristics of an Axial Double Baffles Three Channels Classifier for Coarse Pulverized Coal,” Powder Technology, vol. 400, Article no. 117250, March 2022.

Z. Sun, et al., “CFD Simulation and Performance Optimization of a New Horizontal Turbo Air Classifier,” Advanced Powder Technology, vol. 32, no. 4, pp. 977-986, April 2021.

Z. Sun, et al., “CFD Simulation and Optimization of the Flow Field in Horizontal Turbo Air Classifiers,” Advanced Powder Technology, vol. 28, no. 6, pp. 1474-1485, June 2017.

Z. Sun, et al., “Effects of Fine Particle Outlet on Performance and Flow Field of a Centrifugal Air Classifier,” Chemical Engineering Research and Design, vol. 117, pp. 139-148, January 2017.

L. Gao, et al., “Study on the Cut Size of a Turbo Air Classifier,” Powder Technology, vol. 237, pp. 520-528, March 2013.

R. Liu, et al., “Effects of Axial Inclined Guide Vanes on a Turbo Air Classifier,” Powder Technology, vol. 280, pp. 1-9, August 2015.

Y. Yu, et al., “A New Volute Design Method for the Turbo Air Classifier,” Powder Technology, vol. 348, pp. 65-69, April 2019.

Q. Huang, et al., “Turbo Air Classifier Guide Vane Improvement and Inner Flow Field Numerical Simulation,” Powder Technology, vol. 226, pp. 10-15, August 2012.

Z. Sun, et al., “Structural Optimization of Vortex Finder for a Centrifugal Air Classifier,” Chemical Engineering Research and Design, vol. 166, pp. 220-226, February 2021.

M. Betz, et al., “Effects of Flow Baffles on Flow Profile, Pressure Drop and Classification Performance in Classifiers,” Processes, vol. 9, no. 7, Article no. 1213, July 2021.

H. A. Petit, et al., “Modelling and Optimization of an Inclined Plane Classifier Using CFD-DPM and the Taguchi Method,” Applied Mathematical Modelling, vol. 77, pp. 617-634, January 2020.

M. Barimani, et al., “Particulate Concentration Distribution in Centrifugal Air Classifiers,” Minerals Engineering, vol. 126, pp. 44-51, September 2018.

O. Altun, et al., “Selection and Mathematical Modelling of High Efficiency Air Classifiers,” Powder Technology, vol. 264, pp. 1-8, September 2014.

T. Yamamoto, et al., “Effect of Inner Structure of Centrifugal Separator on Particle Classification Performance,” Powder Technology, vol. 192, no. 3, pp. 268-272, June 2009.

L. Feng, et al., “Classification Performance of Model Coal Mill Classifiers with Swirling and Non-Swirling Inlets,” Chinese Journal of Chemical Engineering, vol. 28, no. 3, pp. 777-784, March 2020.

Z. Sun, et al., “Experimental and CFD Study on a Cyclonic Classifier with New Flow Pattern,” Advanced Powder Technology, vol. 30, no. 10, pp. 2276-2284, October 2019.

R. Guizani, et al., “Effects of the Geometry of Fine Powder Outlet on Pressure Drop and Separation Performances for Dynamic Separators,” Powder Technology, vol. 314, pp. 599-607, June 2017.

K. Elsayed, et al., “Optimization of the Cyclone Separator Geometry for Minimum Pressure Drop Using Mathematical Models and CFD Simulations,” Chemical Engineering Science, vol. 65, no. 22, pp. 6048-6058, November 2010.

X. Mou, et al., “CFD-Based Structural Optimization of Rotor Cage for High-Efficiency Rotor Classifier,” Processes, vol. 9, no. 7, Article no. 1148, June 2021.

Z. Sun, et al., “A New Static Cyclonic Classifier: Flow Characteristics, Performance Evaluation and Industrial Applications,” Chemical Engineering Research and Design, vol. 145, pp. 141-149, May 2019.

Published

How to Cite

Issue

Section

License

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)