A Biogas Desulphurization System with Water Scrubbing

Keywords:

biogas, water scrubbing, hydrogen sulfide, pH, desulphurizationAbstract

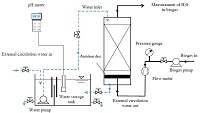

The biogas is renewable energy with very good potential. It is a gas produced by the bacteria transformation of the organic substance under the anaerobic condition. It is a flammable gas because it contains the hydrogen sulfide (H2S) in its composition. It will cause damage to metal equipment and the corrosion of the pipe. So before using the biogas, the desulphurization process should be carried on. The purpose of this study was to design a water scrubbing system for biogas and carry on the performance test of the desulphurization process in the hog farm. In the field test, the biogas flow rate is changed in the water scrubbing cylinder and under different external circulation water flow rate. The H2S concentration in the biogas is detected before and after water scrubbing, and the desulphurization efficiency of biogas was discussed, furthermore, the pH value of water in the water storage tank was measured. When the H2S adsorbed by water was at steady state, whether the pH value of external circulation water can meet the effluent standard was discussed. From the test results, it showed that the removal efficiency of H2S was 47.7% in 30 minutes of water scrubbing time under 120 ℓ of total water amount, 80 cm of water level in the water scrubbing cylinder, 20 ℓ/min of internal circulation water flow rate and 10 ℓ/min of external circulation water flow rate, and 25 ℓ/min of biogas flow rate. The pH value of water in the water storage tank was 6.22, which met the effluent standard of regulation for discharging directly. This system can reduce the H2S content in the biogas, and purify the quality of the biogas. The operation of this system is convenient and the fabrication cost is low, which is suitable for the small-scale hog farm to purify the biogas.

References

M. Kaltschmitt and W. Streicher, “Energie aus biomasse,” Regenerative Energien in Österreich, pp. 339-532, 2009.

S. Pipatmanomai, S. Kaewluan, and T. Vitidsant, “Economic assessment of biogas-to-electricity generation system with H2S removal by activated carbon in small pig farm,” Applied Energy, vol. 86, no. 5, pp. 669-674, May 2009.

C. C. Lien, C. H. Ting, and J. H. Mei. “Piglets comfort with hot water by biogas combustion under controllable ventilation,” Advances in Technology Innovation, vol. 3, no. 2, pp. 86-93, April 2018.

J. Nägele, H. J. Steinbrenner, G. Hermanns, V. Holstein, N. L. Haag, and H. Oechsner, “Innovative additives for chemical desulphurization in biogas processes: a comparative study on iron compound products,” Biochemical Engineering Journal, vol. 121, pp. 181-187, May 2017.

A. L. Kohl and R. Nielsen, Gas purification, 5th ed. Houston: Gulf Publishing Company, 1997.

G. Lastella, C. Testa, G. Cornacchia, M. Notornicola, F. Voltasio, and V. K. Sharma, “Anaerobic digestion of semi-solid organic waste: biogas production and its purification,” Energy Conversion and Management, vol. 43, no. 1, pp. 63-75, January 2002.

S. A. Marzouk, M. H. Al-Marzouqi, M. Teramoto, N. Abdullatif, and Z. M. Ismail, “Simultaneous removal of CO2 and H2S from pressurized CO2-H2S-CH4 gas mixture using hollow fiber membrane contactors,” Separation and purification technology, vol. 86, pp. 88-97, February 2012.

S. Rasi, J. Läntelä, A. Veijanen, and J. Rintala, “Landfill gas upgrading with countercurrent water wash,” Waste Management, vol. 28, no. 9, pp. 1528-1534, 2008.

M. Islamiyaha, T. Soehartantoa, R. Hantoroa, and A. Abdurrahman, “Water scrubbing for removal of CO2 (carbon dioxide) and H2S (hydrogen sulfide) in biogas from manure,” ISSN 2413-5453, 2: 126-131, 2015. DOI: http://dx.doi.org/10.18502/ken.v2i2.367.

R. Kapoor, P. M. V. Subbarao, Shah, V. K. Vijay, G. Shah, S. Sahota, and D. Singh “Factors affecting methane loss from a water scrubbing based biogas upgrading system,” Applied Energy, vol. 208, pp. 1379-1388, December 2017.

Water Quality Protection Division, Environmental Protection Administration, Executive Yuan, Taiwan, ROC. 2017, “The emission standard for chemical industry stipulated by the Environmental Protection Administration,” Article 2, Article 5, Amended Article 2-1, No. 1060101625 Order of Environmental Protection Administration, dated on December 25, 2017.

Published

How to Cite

Issue

Section

License

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. is accepted for publication. Authors can retain copyright of their article with no restrictions.

Since Jan. 01, 2019, AITI will publish new articles with Creative Commons Attribution Non-Commercial License, under The Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.