On the Performance Analysis and Environmental Impact of Concrete with Coal Fly Ash and Bottom Ash

DOI:

https://doi.org/10.46604/ijeti.2023.10229Keywords:

carbon footprint, coal bottom ash, coal fly ash, concreteAbstract

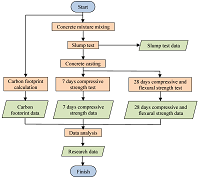

Coal is a commonly used fuel by coal power plants that produce coal fly ash and coal bottom ash (coal FABA) as byproducts. The latest regulation in Indonesia changes coal FABA classification to non-toxic waste, which opens up its utilization possibility. This paper analyses the coal FABA potential from Suralaya Coal Power Plant as concrete material and its environmental impact. To determine coal FABA potential, the methods used in this paper are slump test, compressive strength test, flexural strength test, and carbon footprint calculation. This paper shows that concrete mixture with coal FABA content has a lower slump value, lower compressive strength, and generally lower flexural strength. Furthermore, the carbon footprint calculation result shows that concrete mixture with coal FABA content has lower CO2 emissions than conventional concrete. Finally, the result shows that concrete with coal FABA could be used as non-structural concrete.

References

M. L. D. Jayaranjan, E. D. Van Hullebusch, and A. P. Annachhatre, “Reuse Options for Coal Fired Power Plant Bottom Ash and Fly Ash,” Reviews in Environmental Science and Bio/Technology, vol. 13, no. 4, pp. 467-486, December 2014.

S. Suprapto, “Blending Batubara Untuk Pembangkit Listrik Studi Kasus PLTU Suralaya Unit 1-4,” Jurnal Teknologi Mineral dan Batubara, vol. 5, no. 1, pp. 31-39, January 2009. (In Indonesia)

C. H. Huang, S. K. Lin, C. S. Chang, and H. J. Chen, “Mix Proportions and Mechanical Properties of Concrete Containing Very High-Volume of Class F Fly Ash,” Construction and Building Materials, vol. 46, pp. 71-78, September 2013.

H. A. Alaka and L. O. Oyedele, “High Volume Fly Ash Concrete: The Practical Impact of Using Superabundant Dose of High Range Water Reducer,” Journal of Building Engineering, vol. 8, pp. 81-90, December 2016.

P. Aggarwal, Y. Aggarwal, and S. M. Gupta, “Effect of Bottom Ash as Replacement of Fine Aggregates in Concrete,” Asian Journal of Civil Engineering (Building and Housing), vol. 8, no. 1, pp. 49-62, Febuary 2007.

M. Singh and R. Siddique, “Properties of Concrete Containing High Volumes of Coal Bottom Ash as Fine Aggregate,” Journal of Cleaner Production, vol. 91, pp. 269-278, March 2015.

M. Rafieizonooz, J. Mirza, M. R. Salim, M. W. Hussin, and E. Khankhaje, “Investigation of Coal Bottom Ash and Fly Ash in Concrete as Replacement for Sand and Cement,” Construction and Building Materials, vol. 116, pp. 15-24, July 2016.

A. U. Abubakar and K. S. Baharudin, “Potential Use of Malaysian Thermal Power Plants Coal Bottom Ash in Construction,” International Journal of Sustainable Construction Engineering and Technology, vol. 3, no. 2, pp. 25-37, November 2012.

P. K. De Maeijer, B. Craeye, R. Snellings, H. Kazemi-Kamyab, M. Loots, K. Janssens, et al, “Effect of Ultra-Fine Fly Ash on Concrete Performance and Durability,” Construction and Building Materials, vol. 263, no. 10, article no. 120493, December 2020.

G. Sancheti, K. L. Jain, and S. Bhargava, “Mechanical and Durability Performance of Concrete Made with Waste Marble and Fly Ash,” Jordan Journal of Civil Engineering, vol. 14, no. 3, pp. 305-318, May 2020.

R. Siddique, “Compressive Strength, Water Absorption, Sorptivity, Abrasion Resistance and Permeability of Self-Compacting Concrete Containing Coal Bottom Ash,” Construction and Building Materials, vol. 47, pp. 1444-1450, October 2013.

I. M. Nikbin, S. Rahimi, H. Allahyari, and M. Damadi, “A Comprehensive Analytical Study on the Mechanical Properties of Concrete Containing Waste Bottom Ash as Natural Aggregate Replacement,” Construction and Building Materials, vol. 121, pp. 746-759, September 2016.

K. Muthusamy, M. H. Rasid, G. A. Jokhio, A. M. A. Budiea, M. W. Hussin, and J. Mirza, “Coal Bottom Ash as Sand Replacement in Concrete: A Review,” Construction and Building Materials, vol. 236, article no. 117507, March 2020.

N. Ankur and N. Singh, “Performance of Cement Mortars and Concretes Containing Coal Bottom Ash: a Comprehensive Review,” Renewable and Sustainable Energy Reviews, vol. 149, article no. 111361, October 2021.

J. H. Park, Q. T. Bui, S. H. Jung, and I. H. Yang, “Selected Strength Properties of Coal Bottom Ash (CBA) Concrete Containing Fly Ash Under Different Curing and Drying Conditions,” Materials (Basel), vol. 14, no. 18, article no. 5381, September 2021.

R. Rodríguez-Álvaro, B. González-Fonteboa, S. Seara-Paz, and E. J. Rey-Bouzón, “Masonry Mortars, Precast Concrete and Masonry Units Using Coal Bottom Ash as a Partial Replacement for Conventional Aggregates,” Construction and Building Materials, vol. 283, article no. 122737, May 2021.

M. Rafieizonooz, M. R. Salim, M. H. Hussin, J. Mirza, S. M. Yunus, and E. Khankhaje, “Workability, Compressive Strength and Leachability of Coal Ash Concrete,” Chemical Engineering Transactions, vol. 56, pp. 439-444, 2017.

S. N. Sadon, S. Beddu, S. Naganathan, N. L. M. Kamal, and H. Hassan, “Coal Bottom Ash as Sustainable Material in Concrete–a Review,” Indian Journal of Science and Technology, vol. 10, no. 36, article no. 114595, September 2017.

Peraturan Pemerintah Republik Indonesia Nomor 101 Tahun 2014, PP no. 101, 2014. (In Indonesia)

Penyelenggaraan Perlindungan dan Pengelolaan Lingkungan Hidup, PP no. 22, 2021. (In Indonesia)

A. I Gan, S. Henry, A. Antoni, and D. Hardjito, “Optimasi Penggunaan Fly Ash dan Bottom Ash PLTU Suralaya dalam Pembuatan Paving Block Mutu Tinggi,” Jurnal Dimensi Pratama Teknik Sipil, vol. 7, no. 1, pp. 8-15, Febuary 2018. (In Indonesia)

C. Marthong and T. P. Agrawal, “Effect of Fly Ash Additive on Concrete Properties,” International Journal of Engineering Research and Applications (IJERA), vol. 2, no. 4, pp. 1986-1991, July-August 2012.

P. Sudjono and C. O. Yudhi, “Estimasi Emisi CO2 dari Pembangunan Berbagai Ukuran Rumah Sederhana,” Jurnal Teknik Lingkungan, vol. 17, no. 2, pp. 98-109, October 2011. (In Indonesia)

G. Hammond and C. Jones, “Inventory of Carbon & Energy (ICE), Version 1.6a,” Sustainable Energy Research Team (SERT), Department of Mechanical Engineering, University of Bath, UK, 2008.

K. R. O'Brien, J. Ménaché, and L. M. O'Moore, “Impact of Fly Ash Content and Fly Ash Transportation Distance on Embodied Greenhouse Gas Emissions and Water Consumption in Concrete,” The International Journal of Life Cycle Assessment, vol. 14, no. 7, pp. 621-629, July 2009.

T. Stengel, D. Heinz, and J. Reger, “Life Cycle Assessment of Geopolymer Concrete–What is the Environmental Benefit,” Proceeding of the 24th Biennial Conference, Concrete Institute of Australia, 2009.

C. Heidrich, I. Hinczak, and B. Ryan, “Supplementary cementitious materials (SCMs) Potential to Lower Australia’s Greenhouse Gas Emissions Profile,” Proceedings of ‘Concrete 05’, Melbourne, Australia, 2005, Concrete Institute of Australia, pp.67-74, 2005.

“Faktor Emisi GRK Sistem Ketenagalistrikan Tahun 2019, Kementerian Energi dan Sumber Daya Mineral Republik Indonesia,” https://gatrik.esdm.go.id/assets/uploads/download_index/files/96d7c-nilai-fe-grk-sistem-ketenagalistrikan-tahun-2019.pdf, 2019. (In Indonesia)

IPCC, 2006 Guidelines for National Greenhouse Gas Inventories, Hyama Japan: Institute for Global Environmental Strategies, 2006.

Pedoman Penyelenggaraan Inventarisasi GRK Nasional: Buku II Volume 1– Metodologi Penghitungan Tingkat Emisi Gas Rumah Kaca Kegiatan Pengadaan dan Penggunaan Energi, Kementerian Lingkungan Hidup, 2012. (In Indonesia)

Published

How to Cite

Issue

Section

License

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)