Preparation and Characterization of Carrot Nanocellulose and Ethylene/Vinyl Acetate Copolymer-Based Green Composites

DOI:

https://doi.org/10.46604/ijeti.2023.12375Keywords:

carrot, nanocellulose, ethylene/vinyl acetate copolymer, physical foamingAbstract

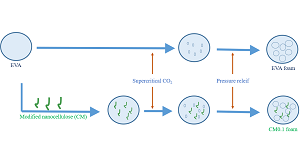

This study aims to investigate the effect of nanocellulose on the properties and physical foaming of ethylene/vinyl acetate (EVA) copolymer. The nanocellulose is prepared from waste carrot residue using the 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) oxidation method (CT) and is further modified through suspension polymerization of methyl methacrylate (MMA) monomer (CM). The obtained nanocellulose samples (CT or CM) are added to EVA to create a series of nanocomposites. Moreover, the EVA and CM/EVA composite were further foamed using supercritical carbon dioxide physical foaming. TEM results show that the average diameters of CT and CM are 24.35 ± 3.15 nm and 30.45 ± 1.86 nm, respectively. The analysis of mechanical properties demonstrated that the tensile strength of pure EVA increased from 10.02 MPa to 13.01 MPa with the addition of only 0.2 wt% of CM. Furthermore, the addition of CM to EVA enhanced the melt strength of the polymer, leading to improvements in the physical foaming properties of the material. The results demonstrate that the pore size of the CM/EVA foam material is smaller than that of pure EVA foam. Additionally, the cell density of the CM/EVA foam material can reach 3.23 × 1011 cells/cm3.

References

I. M. T. Usman, Y. C. Ho, L. Baloo, M. K. Lam, and W. Sujarwo, “A Comprehensive Review on the Advances of Bioproducts from Biomass towards Meeting Net Zero Carbon Emissions (NZCE),” Bioresource Technology, vol. 366, article no. 128167, December 2022.

P. S. Sadalage and K. D. Pawar, “Production of Microcrystalline Cellulose and Bacterial Nanocellulose through Biological Valorization of Lignocellulosic Biomass Wastes,” Journal of Cleaner Production, vol. 327, article no. 129462, December 2021.

G. Siqueira, K. Oksman, S. K. Tadokoro, and A. P. Mathew, “Re-Dispersible Carrot Nanofibers with High Mechanical Properties and Reinforcing Capacity for Use in Composite Materials,” Composites Science and Technology, vol. 123, pp. 49-56, February 2016.

A. Horta-Velázquez and E. Morales-Narváez, “Nanocellulose in Wearable Sensors,” Green Analytical Chemistry, vol. 1, article no. 100009, April 2022.

S. Mondal, “Preparation, Properties and Applications of Nanocellulosic Materials,” Carbohydrate Polymers, vol. 163, pp. 301-316, May 2017.

T. Saito and A. Isogai, “Introduction of Aldehyde Groups on Surfaces of Native Cellulose Fibers by TEMPO-Mediated Oxidation,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, vol. 289, no. 1-3, pp. 219-225, October 2006.

A. Isogai, T. Hänninen, S. Fujisawa, and T. Saito, “Catalytic Oxidation of Cellulose with Nitroxyl Radicals under Aqueous Conditions,” Progress in Polymer Science, vol. 86, pp. 122-148, November 2018.

S. Hu, Y. Zhi, S. Shan, and Y. Ni, “Research Progress of Smart Response Composite Hydrogels Based on Nanocellulose,” Carbohydrate Polymers, vol. 275, article no. 118741, January 2022.

M. K. Sinha, B. R. Das, D. Bharathi, N. E. Prasad, B. Kishore, P. Raj, et al., “Electrospun Nanofibrous Materials for Biomedical Textiles,” Materials Today: Proceedings, vol. 21, part 4, pp. 1818-1826, 2020.

Y. Jia and J. Zhang, “Thermal Conductivity of Ethylene-Vinyl Acetate Copolymers with Different Vinyl Acetate Contents Dependent on Temperature and Crystallinity,” Thermochimica Acta, vol. 708, article no. 179141, February 2022.

A. R. Carmona and H. A. C. Lopera, “A New Composite Made from Luffa Cylindrica and Ethylene Vinyl Acetate (EVA): Mechanical and Structural Characterization for Its Use as Mouthguard (MG),” Journal of the Mechanical Behavior of Biomedical Materials, vol. 126, article no. 105064, February 2022.

K. Park, K. Sadeghi, P. K. Panda, J. Seo, and J. Seo, “Ethylene Vinyl Acetate/Low-Density Polyethylene/Oyster Shell Powder Composite Films: Preparation, Characterization, and Antimicrobial Properties for Biomedical Applications,” Journal of the Taiwan Institute of Chemical Engineers, vol. 134, article no. 104301, May 2022.

P. W. Anggoro, A. A. Anthony, M. Tauviqirrahman, Jamari, A. P. Bayuseno, and A. Han, “Machining Parameter Optimization of EVA Foam Orthotic Shoe Insoles,” International Journal of Engineering and Technology Innovation, vol. 10, no. 3, pp. 179-190, July 2020.

C. Z. P. Junior, R. S. Peruchi, F. de Carvalho Fim, W. D. O. S. Soares, and L. B. da Silva, “Performance of Ethylene Vinyl Acetate Waste (EVA-w) When Incorporated into Expanded EVA Foam for Footwear,” Journal of Cleaner Production, vol. 317, article no. 128352, October 2021.

N. Li, D. Fan, Z. Shi, Y. Xie, M. Li, and T. Tang, “Effect of Ion-Crosslinking on Supercritical CO2 Foaming Behavior and Foam Properties of EVA/ZnO Composites,” Composites Communications, vol. 25, article no. 100760, June 2021.

A. Briand, A. Leybros, O. Doucet, M. Vite, A. Gasmi, J. C. Ruiz, et al., “Deformation-Induced Delamination of Photovoltaic Modules by Foaming Ethylene-Vinyl Acetate with Supercritical CO2,” Journal of CO2 Utilization, vol. 59, article no. 101933, May 2022.

Q. Ren, M. Wu, L. Wang, W. Zheng, Y. Hikima, T. Semba, et al., “Cellulose Nanofiber Reinforced Poly (Lactic Acid) with Enhanced Rheology, Crystallization and Foaming Ability,” Carbohydrate Polymers, vol. 286, article no. 119320, June 2022.

Y. F. Shih, Z. Z. Lai, and V. K. Kotharangannagari, “Preparation and Characterization of Carrot Nanofiber and Their Reinforced Nanocomposite Films,” Key Engineering Materials, vol. 845, pp 15-20, May 2020.

Y. F. Shih, M. Y. Chou, H. Y. Lian, L. R. Hsu, and S. M. Chen-Wei, “Highly Transparent and Impact-Resistant PMMA Nanocomposites Reinforced by Cellulose Nanofibers of Pineapple Leaves Modified by Eco-Friendly Methods,” eXPRESS Polymer Letters, vol. 12, no. 9, pp. 844-854, September 2018.

Y. F. Shih, V. K. Kotharangannagari, and T. C. Tsou, “Development of Eco-Friendly Modified Cellulose Nanofiber Reinforced Polystyrene Nanocomposites: Thermal, Mechanical, and Optical Properties,” Journal of Polymer Research, vol. 27, no. 7, article no.181, July 2020.

H. N. Day, S. J. Hsiao, C. C. Tsao, W. C. Liang, S. J. Liou, and C. L. Wu, Manufacturing Method for Foaming Shoe Materials, T.W. Patent, TWI519401B, February 01, 2016.

K. H. Ho, M. van Meurs, X. Lu, and S. K. Lau, “Interfacial Stabilizing and Reinforcing Effects of Silsesquioxane-Based Hybrid Janus Molecules in Extrusion Supercritical CO2 Foaming of Polypropylene,” Materials & Design, vol. 224, article no. 111345, December 2022.

M. A. Adekoya, S. Liu, S. S. Oluyamo, O. T. Oyeleye, and R. T. Ogundare, “Influence of Size Classifications on the Crystallinity Index of Albizia gummifera Cellulose,” Heliyon, vol. 8, no. 12, article no. e12019, December 2022.

D. Lin, Y. Li, Y. Huang, W. Qin, D. A. Loy, H. Chen, et al., “Properties of Polyvinyl Alcohol Films Reinforced by Citric Acid Modified Cellulose Nanocrystals and Silica Aerogels,” Carbohydrate Polymers, vol. 298, article no. 120116, December 2022.

Y. F. Shih, M. Y. Chou, W. C. Chang, H. Y. Lian, and C. M. Chen, “Completely Biodegradable Composites Reinforced by the Cellulose Nanofibers of Pineapple Leaves Modified by Eco-Friendly Methods,” Journal of Polymer Research, vol. 24, no. 11, article no. 209, November 2017.

W. Zhai, J. Yu, and J. He, “Ultrasonic Irradiation Enhanced Cell Nucleation: An Effective Approach to Microcellular Foams of Both High Cell Density and Expansion Ratio,” Polymer, vol. 49, no. 10, pp. 2430-2434, May 2008.

P. Huang, Y. Su, F. Wu, P. C. Lee, H. Luo, X. Lan, et al., “Extruded Polypropylene Foams with Radially Gradient Porous Structures and Selective Filtration Property via Supercritical CO2 Foaming,” Journal of CO2 Utilization, vol. 60, article no. 101995, June 2022.

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yu-Cian Ke, Ying-Chieh Chao, Chun-Wei Chang, Yeng-Fong Shih

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)