Temperature Compensation Model for Monitoring Sensor in Steel Industry Load Management

DOI:

https://doi.org/10.46604/ijeti.2024.13621Keywords:

power systems, temperature compensation, SVR, improved whale optimization algorithmAbstract

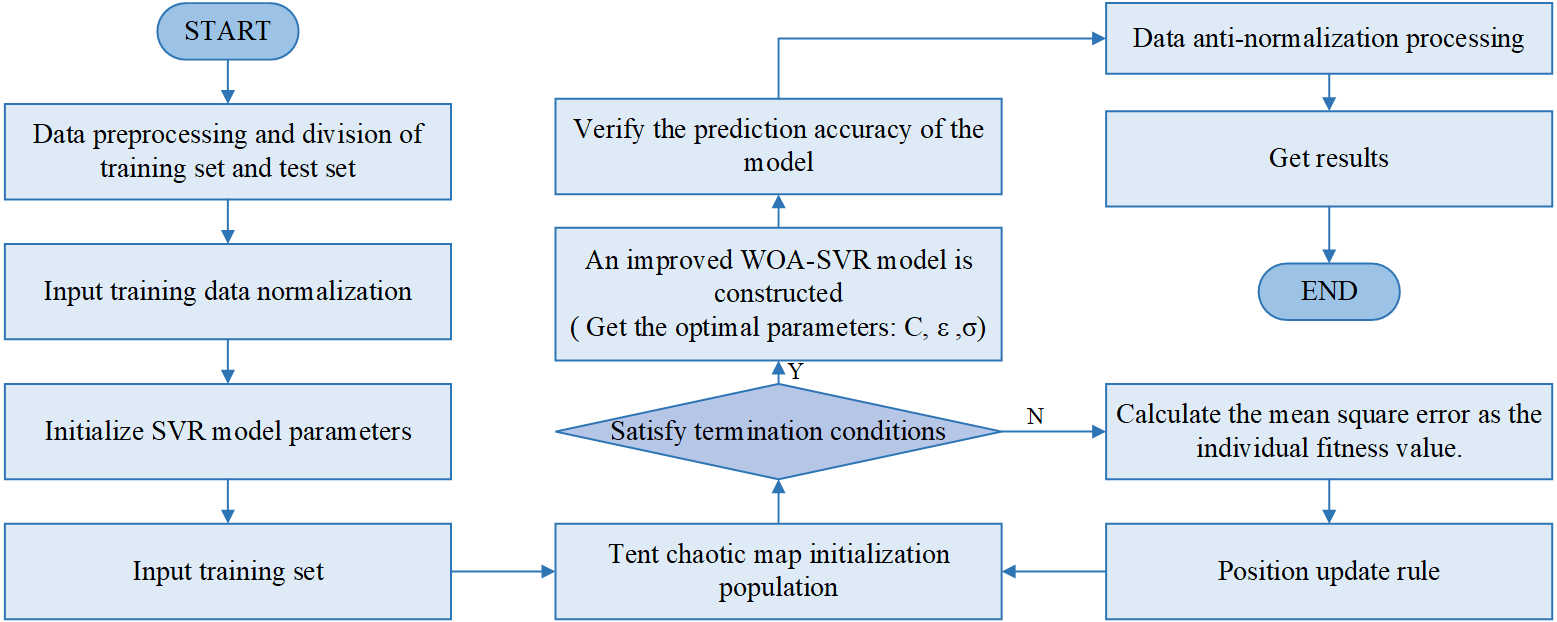

The iron ore industry faces increasing electricity demand due to industrialization, making effective management of electricity demand crucial. This study proposes a temperature compensation model using Support Vector Regression (SVR), aiming to enhance the accuracy of sensors in monitoring electricity demand. An experiment is conducted to assess the impact of temperature on sensor measurements, and a modified Whale Optimization Algorithm is employed to correct the sensor outputs. The proposed model is compared with both PSO-SVR and unimproved WOA-SVR. Results show that the proposed model significantly improves accuracy, achieving a determination coefficient of 0.7882 and a relative standard deviation of the error square sum of 4.6412%. The results of this study not only enhance power demand management in iron mining but also hold potential applications across various industries.

References

Y. D. Wang, D. Wang, and X. P. Shi, “Sustainable Development Pathways of China's Wind Power Industry Under Uncertainties: Perspective from Economic Benefits and Technical Potential,” Energy Policy, vol. 182, article no. 113737, November 2023.

U. K. Vates, B. P. Sharma, N. J. Kanu, E. Gupta, and G. K. Singh, “Modeling and Optimization of IOT Factors to Enhance Agile Manufacturing Strategy-Based Production System Using SCM and RSM,” Smart Science, vol 10, no. 2, pp. 158-173, 2022.

E. Gupta, N. J. Kanu, M. S. Agrawal, A. A. Kamble, A. N. Shaikh, U. K. Vates, et al., “An Insight into Numerical Investigation of Bioreactor for Possible Oxygen Emission on Mars,” Materials Today: Proceedings, vol. 47, no. 14, pp. 4149-4154, 2021.

A. D. Halwe, S. J. Deshmukh, N. J. Kanu, and J. S. Gawande, “Optimization of Combustion Characteristics of Novel Hydrodynamic Cavitation Based Waste Cooking Oil Biodiesel Fueled CI Engine,” SN Applied Sciences, vol. 5, no.2, article no. 65, February 2023.

C. L. Wang, S. D. C. Walsh, Z. H. Weng, M. W. Haynes, D. Summerfield, and A. Feitz, “Green Steel: Synergies between the Australian Iron Ore Industry and the Production of Green Hydrogen,” International Journal of Hydrogen Energy, vol. 48, no. 83, pp. 32277-32293, October 2023.

U. K. Vates, N. J. Kanu, E. Gupta, G. K. Singh, B. P. Sharma, and V. Pandey, “Optimization of Electro Discharge Critical Process Parameters in Tungsten Carbide Drilling Using L9 Taguchi Approach,” Materials Today: Proceedings, vol. 47, no. 11, pp. 3227-3234, 2021.

S. Chavan, N. J. Kanu, S. Shendokar, B. Narkhede, M. K. Sinha, E. Gupta, et al., “An Insight into Nylon 6, 6 Nanofibers Interleaved E-glass Fiber Reinforced Epoxy Composites,” Journal of The Institution of Engineers (India): Series C, vol. 104, no. 1, pp. 15-44, February 2023.

B. K. Gonfa, D. Sinha, U. K. Vates, I. A. Badruddin, M. Hussien, S. Kamangar, et al., “Investigation of Mechanical and Tribological Behaviors of Aluminum Based Hybrid Metal Matrix Composite and Multi-Objective Optimization,” Materials, vol. 15, no. 16, article no. 5607, August 2022.

X. Li, S. C. Ke, Y. Li, W. Jin, X. H. Fu, G. W. Fu, et al., “Temperature Compensation Based on BP Neural Network with Small Sample Data for Chloride Ions Optical Fiber Probe,” Optics & Laser Technology, vol. 176, article no. 110973, September 2024.

Y. Wang, X. L. Sun, T. T. Huang, L. Y. Ye, and K. C. Song, “Cold Starting Temperature Drift Modeling and Compensation of Micro-Accelerometer Based on High-Order Fourier Transform,” Micromachines, vol. 13, no. 3, article no. 413, March 2022.

W. J. Sheng, H. T. Lou, J. F. Pan, J. X. Wen, and G.D. Peng, “Online Temperature Drift Compensation of Fabry-Perot Filter Based on Machine Learning and Linear Fitting,” Sensors and Actuators A: Physical, vol.363, article no. 114774, December 2023.

L. Gan, J. B. Wang, and, Y. T. Zhou, “A Sub-Millinewton Resolution Biaxial Force Sensor with Temperature Self-Compensation for Vascular Intervention,” Sensors and Actuators A: Physical, vol. 364, article no. 114833, December 2023.

H. Zhang, W. P. Chen, L. Yin, and Q. Fu, “Design of MEMS Gyroscope Interface ASIC with On-chip Temperature Compensation,” Measurement, vol. 220, article no. 113331, October 2023.

S. Tian, M. Xiong, M. Chen, Y. Cheng, S. J. Deng, H. Q. Liu, et al., “Highly Sensitive Cascaded Fiber SPR Sensor With Temperature Compensation,” Optics Communications, vol. 233, article no. 129277, April 2023.

S. Zhao, C. F. Guo, C. N. ke, Y. L. Zhou, and X. W. Shu, “Temperature Drift Compensation of Fiber Strapdown Inertial Navigation System Based on GSA-SVR,” Measurement, vol. 195, article no. 111117, May 2022.

M. J. Ouyang, J. L. Gao, A. Li, X. G. Zhang, C. Shen, and H. L. Cao, “Micromechanical Gyroscope Temperature Compensation Based on Combined LSTM-SVM-DBN Algorithm,” Sensors and Actuators A: Physical, vol. 369, article no.115128, April 2024.

P. Y. Chen, Z. Y. Mao, C. Y. Wang, C. Y. Lu, and J. Q. Li, “A Novel RBFNN-UKF-Based SOC Estimator for Automatic Underwater Vehicles Considering a Temperature Compensation Strategy,” Journal of Energy Storage, vol. 72, Part B, article no. 108373, November 2023.

F. X. Yu, C. N. Li, and Y. H. Shao, “DNTC: An Unsupervised Deep Networks for Temperature Compensation in Non-Stationary Data,” Engineering Applications of Artificial Intelligence, vol. 127, Part B, article no. 107319, January 2024.

X. L. Zhao, Y. Chen, G. H. Wei, L. L. Pang, and C. X. Xu, “A Comprehensive Compensation Method for Piezoresistive Pressure Sensor Based on Surface Fitting and Improved Grey Wolf Algorithm,” Measurement, vol. 207, article no. 112387, February 2023.

L. J. Tian, Y. X. Niu, C. W. Huang, H. Y. Li, Y. Pang, and Y. Q. Yang, “A Novel Temperature-Compensation Method Based on Correlation Analysis for Multi-FOG INS,” Chinese Journal of Aeronautics, vol. 36, no. 6, pp. 279-287, June 2023.

S. Liu, H. Z. Yang, Z. Q. Mei, X. Y. Xu, and Q. E. He, “Ultra-Wideband High Accuracy Distance Measurement Based on Hybrid Compensation of Temperature and Distance Error,” Measurement, vol. 206, article no. 112276, January 2023.

E. D. Bobobee, S. L. Wang, P. Takyi-Aninakwa, C. Y. Zou, E. Appiah, and N. Hai, “Improved Particle Swarm Optimization–Long Short-Term Memory Model with Temperature Compensation Ability for the Accurate State of Charge Estimation of Lithium-Ion Batteries,” Journal of Energy Storage, vol. 84, Part A, article no. 110871, April 2024.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Liyuan Sun, Zeming Yang, Nan Pan, Shilong Chen, Yaoshen He, Junwei Yang

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)