Feasibility of 3D Printing on Environmentally Friendly Cementless Materials with Low Thermal Conductivity

DOI:

https://doi.org/10.46604/ijeti.2024.13853Keywords:

3D printing technology, co-fired fly ash, thermal conductivity, circular economyAbstract

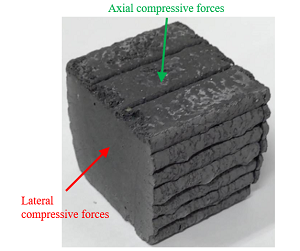

This study investigates ultra-fine fly ash (UFA) and co-fired fly ash (CFA) to produce binary cementless binders without alkali activators and determines the effects of molding temperatures (17 ℃, 50 ℃, 60 ℃, 70 ℃, 80 ℃, and 90 ℃) on thermal conductivity and microstructures. The pastes are subjected to flow and expansion tests to verify the mixing state of the two industrial by-products for a fixed water-to-binder ratio of 0.4. Compressive strength, water absorption, density, thermal conductivity, and scanning electron microscope analyses determine material properties and the optimal molding temperature. Results reveal that higher hardening temperatures lead to higher water absorption and lower density. The 50 ℃ specimen exhibits the lowest thermal conductivity of 0.1796 W/m·K at 56 days. The printed specimens with UFA and CFA at a 1:1 ratio achieve a 28-day compressive strength of 9 MPa and a thermal conductivity of 0.2064 W/m·K.

References

L. Poudyal and K. Adhikari, “Environmental Sustainability in Cement Industry: An Integrated Approach for Green and Economical Cement Production,” Resources, Environment and Sustainability, vol. 4, article no. 100024, 2021.

X. Zhang, C. Bai, Y. Qiao, X. Wang, D. Jia, H. Li, et al., “Porous Geopolymer Composites: A Review,” Composites Part A: Applied Science and Manufacturing, vol. 150, article no. 106629, 2021.

T. M. Do, G. O. Kang, and Y. S. Kim, “Development of a New Cementless Binder for Controlled Low Strength Material (CLSM) Using Entirely By-Products,” Construction and Building Materials, vol. 206, pp. 576-589, 2019.

W. T. Lin, K. L. Lin, K. Korniejenko, L. Fiala, A. Cheng, and J. Chen, “Composite Properties of Non-Cement Blended Fiber Composites Without Alkali Activator,” Materials, vol. 13, no. 6, article no. 1443, 2020.

W. Zhang, H. Choi, T. Sagawa, and Y. Hama, “Compressive Strength Development and Durability of an Environmental Load-Reduction Material Manufactured Using Circulating Fluidized Bed Ash and Blast-Furnace Slag,” Construction and Building Materials, vol. 146, pp. 102-113, 2017.

W. S. Yum, J. Yu, D. Jeon, H. Song, S. Sim, D. H. Kim, et al., “Mechanical and Durability Properties of Cementless Concretes Made Using Three Types of CaO-Activated GGBFS Binders,” Materials, vol. 15, no. 1, article no. 271, 2022.

W. T. Lin, “Reactive Ultra-Fine Fly Ash as an Additive for Cement-Based Materials,” Materials Today Communications, vol. 25, article no. 101466, 2020.

W. T. Lin, K. L. Lin, K. Korniejenko, and L. Fiala, “Comparative Analysis Between Fly Ash Geopolymer and Reactive Ultra-Fine Fly Ash Geopolymer,” International Journal of Engineering and Technology Innovation, vol. 11, no. 3, pp. 161-170, 2021.

H. Zhao, Y. Wang, X. Liu, X. Wang, Z. Chen, Z. Lei, et al., “Review on Solid Wastes Incorporated Cementitious Material Using 3D Concrete Printing Technology,” Case Studies in Construction Materials, vol. 21, article no. e03676, 2024.

A. Hasani and S. Dorafshan, “Transforming Construction? Evaluation of the State of Structural 3D Concrete Printing in Research and Practice,” Construction and Building Materials, vol. 438, article no. 137027, 2024.

A. Yousaf, A. Al Rashid, and M. Koç, “3D Printing of Alkali-Activated Geopolymers for Sustainable and Circular Economy Advancements,” Circular Economy, vol. 3, no. 3, article no. 100101, 2024.

R. T. Fongang, J. Pemndje, P. N. Lemougna, U. C. Melo, C. P. Nanseu, B. Nait-Ali, et al., “Cleaner Production of the Lightweight Insulating Composites: Microstructure, Pore Network and Thermal Conductivity,” Energy and Buildings, vol. 107, pp. 113-122, 2015.

M. Łach, K. Plawecka, A. Bak, K. Lichocka, K. Korniejenko, A. Cheng, et al., “Determination of the Influence of Hydraulic Additives on the Foaming Process and Stability of the Produced Geopolymer Foams,” Materials, vol. 14, no. 17, article no. 5090, 2021.

W. T. Lin, “Development of Cementless Binder for Low Thermal Conductivity Materials: Reactive Ultra-Fine Fly Ash Mixed with Co-Fired Fly Ash,” Case Studies in Construction Materials, vol. 16, article no. e00899, 2022.

P. K. De Maeijer, B. Craeye, R. Snellings, H. Kazemi-Kamyab, M. Loots, K. Janssens, et al., “Effect of Ultra-Fine Fly Ash on Concrete Performance and Durability,” Construction and Building Materials, vol. 263, article no. 120493, 2020.

C. R. Shearer, J. L. Provis, S. A. Bernal, and K. E. Kurtis, “Alkali-Activation Potential of Biomass-Coal Co-Fired Fly Ash,” Cement and Concrete Composites, vol. 73, pp. 62-74, 2016.

V. Corinaldesi, A. Mazzoli, and R. Siddique, “Characterization of Lightweight Mortars Containing Wood Processing By-Products Waste,” Construction and Building Materials, vol. 123, pp. 281-289, 2016.

J. Dang, X. Tang, J. Xiao, and A. Han, “Influence of Alkaline Activator and Precursor on the Foam Characterization and Alkali-Activated Foamed Concrete Properties,” Cement and Concrete Composites, vol. 145, article no. 105341, 2024.

E. P. Kearsley and P. J. Wainwright, “Porosity and Permeability of Foamed Concrete,” Cement and Concrete Research, vol. 31, no. 5, pp. 805-812, 2001.

S. Shakouri, Ö. Bayer, and S. T. Erdoğan, “Development of Silica Fume-Based Geopolymer Foams,” Construction and Building Materials, vol. 260, article no. 120442, 2020.

T. Li, F. Huang, J. Zhu, J. Tang, and J. Liu, “Effect of Foaming Gas and Cement Type on the Thermal Conductivity of Foamed Concrete,” Construction and Building Materials, vol. 231, article no. 117197, 2020.

W. She, Y. Chen, Y. Zhang, and M. R. Jones, “Characterization and Simulation of Microstructure and Thermal Properties of Foamed Concrete,” Construction and Building Materials, vol. 47, pp. 1278-1291, 2013.

S. Feng, Y. Gao, H. Xiao, and C. Xue, “Influence of Fibers and Bubble Structure on Thermal Conductivity and Mechanical Performances of Foam Concrete,” Construction and Building Materials, vol. 445, article no. 137956, 2024.

H. Yuan, Z. Ge, R. Sun, X. Xu, Y. Lu, Y. Ling, et al., “Drying Shrinkage, Durability and Microstructure of Foamed Concrete Containing High Volume Lime Mud-Fly Ash,” Construction and Building Materials, vol. 327, article no. 126990, 2022.

D. Chen, M. Chen, Y. Zhang, X. Yang, J. Zhang, Y. Zhao, et al., “Development of an Environmental Foamed Concrete Incorporating Recycled Cement Concrete Powder with Carbonation,” Construction and Building Materials, vol. 422, article no. 135833, 2024.

Y. Wu, J. Y. Wang, P. J. M. Monteiro, and M. H. Zhang, “Development of Ultra-Lightweight Cement Composites with Low Thermal Conductivity and High Specific Strength for Energy Efficient Buildings,” Construction and Building Materials, vol. 87, pp. 100-112, 2015.

J. Wang, M. Feng, T. Ma, Y. Zhang, and Y. Wang, “The Effects of Desulfurized Gypsum on the Mechanical Properties of Dredged Clay with High Initial Water Content Stabilized by Ternary Geopolymer,” Case Studies in Construction Materials, vol. 20, article no. e02907, 2024.

K. Korniejenko, K. Pławecka, P. Bazan, B. Figiela, B. Kozub, K. Mróz, et al., “Green Building Materials for Circular Economy - Geopolymer Foams,” Proceedings of Engineering and Technology Innovation, vol. 25, pp. 26-34, 2023.

M. Łach, J. Mikuła, W. T. Lin, P. Bazan, B. Figiela, and K. Korniejenko, “Development and Characterization of Thermal Insulation Geopolymer Foams Based on Fly Ash,” Proceedings of Engineering and Technology Innovation, vol. 16, pp. 23-29, 2020.

M. Łach, A. Bąk, K. Pławecka, and M. Hebdowska-Krupa, “Possibility of Using a Geopolymer Containing Phase Change Materials as a Sprayed Insulating Coating - Preliminary Results,” Emerging Science Innovation, vol. 2, pp. 01-08, 2024.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Wei-Ting Lin, Dariusz Mierzwiński, Marek Hebda, Andina Sprince, Gábor Mucsi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)