A Systematic Review of Coal Mine Dust Suppression Methods Based on Numerical Simulations and Experimental Investigations

DOI:

https://doi.org/10.46604/ijeti.2024.14818Keywords:

coal mine, dust suppression, structural improvement, chemical modification, operating environmentAbstract

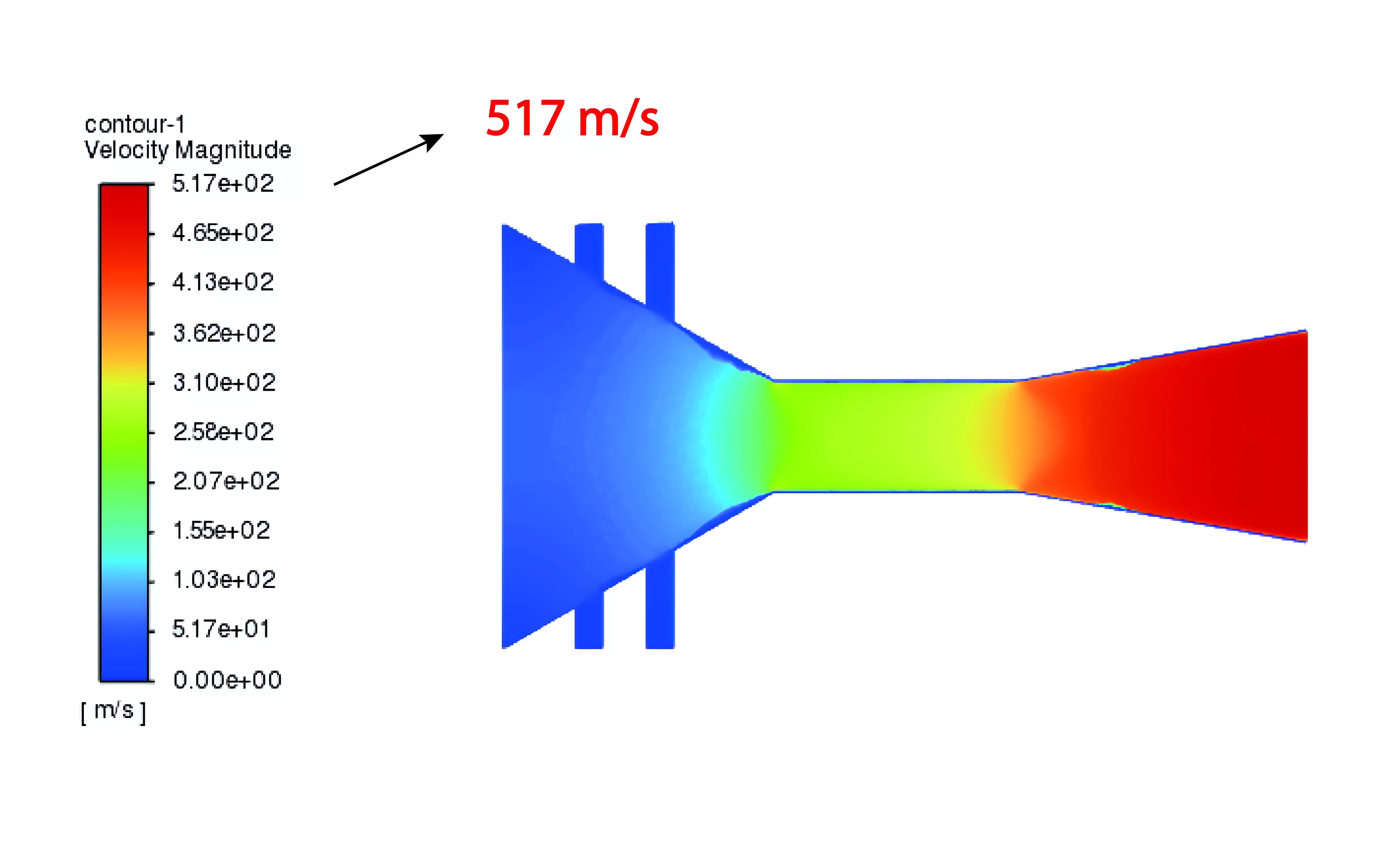

Large quantities of dust are generated during coal mining and transportation, posing a threat to workers’ health. Therefore, this article conducts a systematic review of the literature on coal mine dedusting. This study examines coal mine dust suppression methods by integrating numerical simulations and experiments, focusing on four aspects: the structural improvement of the dust remover, chemical modification, the optimization of the operating environment, and the ventilation system. The structural improvement of a dust remover primarily involves optimizing the nozzle’s structure and size, particularly the Laval structure. The findings indicate that alterations in the surface structure of the Laval nozzle’s contraction section have minimal effect on the airflow velocity. Chemical modification of the dust remover can enhance the wetting properties of coal dust and includes non-phytochemical and phytochemical modification. Molecular Dynamics (MD) simulations are frequently employed in chemical modification. The optimization of the operating environment for dust removers focuses predominantly on spray pressure optimization.

References

W. Jiang, X. Xu, Z. Wen, and L. Wei, “Applying the Similarity Theory to Model Dust Dispersion during Coal-mine Tunneling,” Process Safety and Environmental Protection, vol. 148, pp. 415-427, 2021.

S. Tang, M. D. Ibrahim, A. R. H. Rigit, W. Zhang, and C. Wei, “Analysis of Atomization Performance of Linear Laval Nozzle under Varied Water Pressures Based on VOF and DPM Models,” International Journal of Engineering and Technology Innovation, vol. 14, no. 4, pp. 335-354, 2024.

S. Tang, M. D. Ibrahim, A. R. H. Rigit, W. Zhang, and C. Wei, “Experimental Analysis of the Effect of Water Pressure on the Atomization Performance of a Linear Laval Nozzle and Comparison with Numerical Analysis,” Revista Matéria, vol. 29, no. 4, article no. e20240460, 2024.

T. Zhang, X. Mu, S. Ge, S. Li, S. Ren, S. Zhao, et al., “Supersonic Coaxial Aerodynamic Atomization Dust Removal Technology,” Powder Technology, vol. 444, article no. 120076, 2024.

S. Tang, M. D. Ibrahim, A. R. H. Rigit, W. Zhang, and C. Wei, “A Systematic Review of Dust Suppression Methods by Experiment Based on Intelligent Technology in the Coal Mines,” Journal of Electrical Systems, vol. 20, no. 3, pp. 882-893, 2024.

B. Ren, G. Zhou, M. Song, B. Jiang, Y. Zheng, T. Fan, et al., “Preparation of Crust Type Dust Suppression Gel Based on Plant Extraction Technology for Ginkgo Biloba Leaves: Characterization, Properties, and Function Mechanism,” Processes, vol. 12, no. 1, article no. 224, 2024.

S. Ren, D. Jing, S. Ge, Y. Chen, and P. Chang, “Investigate the Optimum Design of Atomizing Nozzles for Coal Dust Suppression by Using Multifactor Level Response Surface Methodology,” Process Safety and Environmental Protection, vol. 190, Part A, pp. 245-261, 2024.

W. Nie, J. Li, H. Peng, C. Xu, S. Zhang, X. Cha, et al., “Study of Spray Atomization Law and Dust Suppression Effect of a Wet Dust Catcher on a Hydraulic Support,” Energy, vol. 305, article no. 132296, 2024.

H. Zheng, B. Jiang, H. Wang, and Y. Zheng, “Experimental and Numerical Simulation Study on Forced Ventilation and Dust Removal of Coal Mine Heading Surface,” International Journal of Coal Science & Technology, vol. 11, no. 1, article no. 13, 2024.

H. Peng, W. Nie, P. Cai, Q. Liu, Z. Liu, and S. Yang, “Development of a Novel Wind-assisted Centralized Spraying Dedusting Device for Dust Suppression in a Fully Mechanized Mining Face,” Environmental Science and Pollution Research, vol. 26, no. 4, pp. 3292-3307, 2019.

H. Peng, W. Nie, X. Zhang, C. Xu, X. Meng, W. Cheng, et al., “Research on the Blowing-Spraying Synergistic Dust Removal Technology for Clean Environment in Large-scale Mechanization Coal Mine,” Fuel, vol. 324, Part B, article no. 124508, 2022.

H. Peng, W. Nie, H. Yu, W. Cheng, P. Bai, Q. Liu, et al., “Research on Mine Dust Suppression by Spraying: Development of an Air-assisted PM10 Control Device based on CFD Technology,” Advanced Powder Technology, vol. 30, no. 11, pp. 2588-2599, 2019.

H. Peng, W. Cheng, Y. Guo, C. Xu, C. Guo, Q. Ma, et al., “Study on the Spray Field Distribution of the Roadway Full-Section Water Curtain Device and its Effect on the Settlement of PM2.5,” Process Safety and Environmental Protection, vol. 143, pp. 101-113, 2020.

T. Zhang, D. Jing, S. Ge, J. Wang, and X. Chen, “Supersonic Antigravity Aerodynamic Atomization Dusting Nozzle based on the Laval Nozzle and Probe Jet,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 42, no. 6, article no. 335, 2020.

W. Yin, G. Zhou, and D. Gao, “Simulation Analysis and Engineering Application of Distribution Characteristics about Multi-stage Atomization Field for Cutting Dust in Fully Mechanized Mining Face,” Advanced Powder Technology, vol. 30, no. 11, pp. 2600-2615, 2019.

Q. Ma, W. Nie, S. Yang, C. Xu, H. Peng, Z. Liu, et al., “Effect of Spraying on Coal Dust Diffusion in a Coal Mine based on a Numerical Simulation,” Environmental Pollution, vol. 264, article no. 114717, 2020.

G. Zhai, W. Zhang, Y. Li, X. Lu, and W. Hu, “Experimental Research and Numerical Simulation of Ejector Precipitator in a Fully Mechanized Mining Face,” Arabian Journal for Science Engineering, vol. 45, no. 11, pp. 9815-9833, 2020.

W. Nie, X. Cha, Q. Bao, H. Peng, C. Xu, S. Zhang, et al., “Study on Dust Pollution Suppression of Mine Wind-Assisted Spray Device based on Orthogonal Test and CFD Simulation,” Energy, vol. 263, Part B, article no. 125590, 2023.

T. Zhang, D. Jing, S. Ge, J. Wang, X. Chen, and S. Ren, “Dust Removal Characteristics of a Supersonic Antigravity Siphon Atomization Nozzle,” Advances in Mechanical Engineering, vol. 12, no. 12, 2020.

T. Zhang, D. Jing, S. Ge, J. Wang, X. Meng, and S. S. Ren, “Numerical Simulation of the Dimensional Transformation of Atomization in a Supersonic Aerodynamic Atomization Dust-removing Nozzle based on Transonic Speed Compressible Flow,” International Journal of Coal Science and Technology, vol. 7, no. 3, pp. 597-610, 2020.

Z. Xi, M. Jiang, C. Sun, and X. Tu, “Controlling the Coal Dust at Transshipment Point: A Study of the Foam-sol Foaming Device,” International Journal of Mining Science and Technology, vol. 24, no. 5, pp. 625-630, 2014.

Q. Bao, W. Nie, C. Liu, H. Zhang, H. Wang, H. Jin, et al., “The Preparation of a Novel Hydrogel based on Crosslinked Polymers for Suppressing Coal Dusts,” Journal of Cleaner Production, vol. 249, article no. 119343, 2020.

M. Yuan, W. Nie, W. Zhou, J. Yan, Q. Bao, C. Guo, et al., “Determining the Effect of the Non-ionic Surfactant AEO9 on Lignite Adsorption and Wetting via Molecular Dynamics (MD) Simulation and Experiment Comparisons,” Fuel, vol. 278, article no. 118339, 2020.

W. Niu, W. Nie, M. Yuan, Q. Bao, W. Zhou, J. Yan, et al., “Study of the Microscopic Mechanism of Lauryl Glucoside Wetting Coal Dust: Environmental Pollution Prevention and Control,” Journal of Hazardous Materials, vol. 412, article no. 125223, 2021.

B. Ji, B. Jiang, L. Yuan, C. Yu, G. Zhou, Y. Zhao, et al., “Experimental and Molecular Dynamics Simulation Study on the Influence of SDS and JFC Composite Ratios on Bituminous Coal Wettability,” Process Safety and Environmental Protection, vol. 174, pp. 473-484, 2023.

M. Gao, H. Li, Y. Zhao, Y. Liu, W. Zhou, L. Li, et al., “Mechanism of Micro-wetting of Highly Hydrophobic Coal Dust in Underground Mining and New Wetting Agent Development,” International Journal of Mining Science and Technology, vol. 33, no. 1, pp. 31-46, 2023.

B. Ren, L. Yuan, G. Zhou, S. Li, Q. Meng, K. Wang, et al., “Effectiveness of Coal Mine Dust Control: A New Technique for Preparation and Efficacy of Self-adaptive Microcapsule Suppressant,” International Journal of Mining Science and Technology, vol. 32, no. 6, pp. 1181-1196, 2022.

R. Xu, H. Yu, H. Dong, Y. Ye, and S. Xie, “Preparation and Properties of Modified Starch-based Low Viscosity and High Consolidation Foam Dust Suppressant,” Journal of Hazardous Materials, vol. 452, article no. 131238, 2023.

F. Han, Y. Peng, Y. Zhao, P. Yang, and F. Hu, “Comparative Investigation of Methods for Evaluating the Wettability of Dust Suppression Reagents on Coal Dust,” Journal of Molecular Liquids, vol. 399, article no. 124380, 2024.

Y. Yu, C. Wang, B. Zhou, W. Cheng, Y. Liu, and S. Li, “Consolidation Performance and Mechanism of Composite Dust Suppressant Based on Graft Modification,” Journal of Applied Polymer Science, vol. 141, no. 41, article no. e56077, 2024.

Y. Liu, H. Li, J. Xie, L. Li, J. Deng, C. Qiu, et al., “Experimental and Molecular Simulation Study on the Influence of Chain Length and Anion Structure of Ionic Liquids on the Wettability of Highly Hydrophobic Bituminous Coal,” Journal of Molecular Liquids, vol. 411, article no. 125819, 2024.

H. Dong, H. Yu, R. Xu, Y. Cheng, W. Cheng, and D. Zhao, “Research on Application Effect and Mechanism of Degradable Multifunctional Dust Suppression Foam in Coal Mines,” Journal of Environmental Chemical Engineering, vol. 12, no. 3, article no. 112694, 2024.

M. Liu, F. Han, Y. Zhao, F. Hu, G. Niu, and Gao, H. “Study on Dynamic Characteristics of Anionic Surfactants Containing Ethoxy Groups Wetting Bituminous Coal,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, vol. 700, article no. 134699, 2024.

R. Wang, H. Yu, Y. Xie, W. Li, and H. Qi, “Study on Protein-polysaccharide Environmental Foam Dust Suppressant Based on Maillard Reaction,” Journal of Molecular Liquids, vol. 410, article no. 125644, 2024.

P. Wang, S. Shen, L. Zhou, and D. Liu, “Turbulent Aggregation and Deposition Mechanism of Respirable Dust Pollutants under Wet Dedusting using a Two-Fluid Model with the Population Balance Method,” International Journal of Environmental Research and Public Health, vol. 16, no. 18, article no. 3359, 2019.

S. Yang, W. Nie, S. Lv, Z. Liu, H. Peng, X. Ma, et al., “Effects of Spraying Pressure and Installation Angle of Nozzles on Atomization Characteristics of External Spraying System at a Fully-mechanized Mining Face,” Powder Technology, vol. 343, pp. 754-764, 2019.

H. Yu, W. Cheng, Y. Xie, and H. Peng, “Spray Dedusting Scheme under Hybrid Ventilation at a Fully Mechanized Excavation Face,” Environmental Science and Pollution Research, vol. 27, no. 8, pp. 7851-7871, 2020.

W. Nie, X. Cha, Q. Bao, H. Peng, C. Xu, S. Zhang, et al., “Study on Dust Pollution Suppression of Mine Wind-assisted Spray Device based on Orthogonal Test and CFD Simulation,” Energy, vol. 263, Part B, article no. 125590, 2023.

W. Nie, F. Liu, H. Peng, J. Li, C. Xu, X. Cha, et al., “Optimization of Wind-and-water Coordinated Dust Reduction Device for Coal Mine Return Airway Based on CFD Technology,” Powder Technology, vol. 444, article no. 119932, 2024.

C. Xu, W. Nie, H. Peng, S. Zhang, F. Liu, S. Yi, et al., “Numerical Simulation of the Dynamic Wetting of Coal Dust by Spray Droplets,” Energy, vol. 270, article no. 126667, 2023.

P. Wang, K. Zhang, and R. Liu, “Influence of Air Supply Pressure on Atomization Characteristics and Dust-suppression Efficiency of Internal-mixing Air-assisted Atomizing Nozzle,” Powder Technology, vol. 355, pp. 393-407, 2019.

H. Han, P. Wang, Y. Li, R. Liu, and C. Tian, “Effect of Water Supply Pressure on Atomization Characteristics and Dust-reduction Efficiency of Internal Mixing Air Atomizing Nozzle,” Advanced Powder Technology, vol. 31, no. 1, pp. 252-268, 2020.

C. Wang, S. Lu, M. Li, Y. Zhang, Z. Sa, J. Liu, et al., “Study on the Dust Removal and Temperature Reduction Coupling Performances of Magnetized Water Spray,” Environmental Science and Pollution Research, vol. 29, no. 4, pp. 6151-6165, 2022.

Y. Li, P. Wang, R. Liu, and R. Gao, “Optimization of Structural Parameters and Installation Position of the Wall-mounted Air Cylinder in the Fully Mechanized Excavation Face based on CFD and Orthogonal Design,” Process Safety and Environmental Protection, vol. 130, pp. 344-358, 2019.

Y. Li, P. Wang, R. Liu, Y. Jiang, and H. Han, “Determination of the Optimal Axial-to-radial Flow Ratio of the Wall-mounted Swirling Ventilation in Fully Mechanized Excavation Face,” Powder Technology, vol. 360, pp. 890-910, 2020.

J. Wei, X. Xu, and W. Jiang, “Influences of Ventilation Parameters on Flow Field and Dust Migration in an Underground Coal Mine Heading,” Scientific Reports, vol. 10, article no. 8563, 2020.

Y. Hua, W. Nie, L. Guo, X. Cai, and L. Cheng, “The Control Effect of 3D Spiral Wind-curtain Generator on Respirable Dust Pollution during Tunnelling Process,” Environmental Science Pollution Research, vol. 28, no. 48, pp. 68212-68228, 2021.

D. Jing, X. Jia, S. Ge, T. Zhang, and M. Ma, “Numerical Simulation and Experimental Study of Vortex Blowing Suction Dust Control in a Coal Yard with Multiple Dust Production Points,” Powder Technology, vol. 388, pp. 554-565, 2021.

S. Ren, D. Jing, S. Ge, M. Ma, M. W. A. Asad, and P. Chang, “Research and Development of Vortex Suction Dedusting Device Based on Multi-factor Horizontal Response Surface Method,” Journal of Cleaner Production, vol. 442, article no. 140916, 2024.

W. Nie, J. Wan, C. Xu, H. Peng, Y. Dou, and H. Li, “High-precision Measurement of Respirable Coal Dust Mass Concentration: A Dual-wavelength Complementary Laser Optical Sensor Approach Based on Mie Scattering,” Optics and Lasers in Engineering, vol. 186, article no. 108766, 2025.

C. Xu, W. Nie, Z. Liu, H. Peng, S. Yang, and Q. Liu, “Multi-factor Numerical Simulation Study on Spray Dust Suppression Device in Coal Mining Process,” Energy, vol. 182, pp. 544-558, 2019.

W. Nie, B. Yang, T. Du, H. Peng, X. Zhang, and Y. Zhang, “Dynamic Dispersion and High-rise Release of Coal Dust in the Working Surface of a Large-scale Mine and Application of a New Wet Dust Reduction Technology,” Journal of Cleaner Production, vol. 351, article no. 131356, 2022.

X. Zhao, Z. Shen, B. Bharti, F. Han, S. Feng, J. Du, and Y. Li, “Research on Chlorine Salt Antifreeze Road Dust Suppressants for Open-pit coal Mines,” Atmospheric Pollution Research, vol. 15, no. 8, article no. 102161, 2024.

G. Zhou, B. Feng, W. Yin, and J. Wang, “Numerical Simulations on Airflow-dust Diffusion Rules with the Use of Coal Cutter Dust Removal Fans and Related Engineering Applications in a Fully-mechanized Coal Mining Face,” Powder Technology, vol. 339, pp. 354-367, 2018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Shanshan Tang, Mohd Danial Ibrahim, Andrew Ragai Henry Rigit, Wei Zhang, Chaokun Wei

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)