Tool Wear Prediction Based on Adaptive Feature and Temporal Attention with Long Short-Term Memory Model

DOI:

https://doi.org/10.46604/ijeti.2024.13387Keywords:

feature attention, temporal attention, tool wear, LSTMAbstract

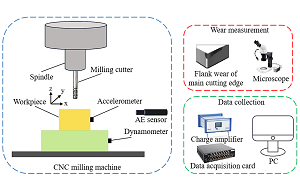

Effective monitoring of tool wear status can improve productivity and reduce losses. In previous studies, extensive feature selection was required when using the traditional machine learning method. The gating mechanism in the traditional long short-term memory (LSTM) model may incur information loss and a weaker representation of global sequential dependencies in handling long sequences. This paper aims to enhance the performance of the LSTM model in tool wear prediction by combining feature and temporal attention. Firstly, the original vibration signal is divided into sub-sequences and related features extracted. Secondly, the ability to capture global sequential dependencies using the LSTM model is improved by feature and temporal attention. Finally, a fully connected layer is used to predict tool wear values. Compared to traditional LSTM, the proposed method performs best in three evaluation metrics, RMSE, MAE, and the coefficient of determination.

References

D. Kong, Y. Chen, and N. Li, “Gaussian Process Regression for Tool Wear Prediction,” Mechanical Systems and Signal Processing, vol. 104, pp. 556-574, May 2018.

X. Zhang, Y. Gao, Z. Guo, W. Zhang, J. Yin, and W. Zhao, “Physical Model-Based Tool Wear and Breakage Monitoring in Milling Process,” Mechanical Systems and Signal Processing, vol. 184, article no. 109641, February 2023.

G. Wang and F. Zhang, “A Sequence-to-Sequence Model with Attention and Monotonicity Loss for Tool Wear Monitoring and Prediction,” IEEE Transactions on Instrumentation and Measurement, vol. 70, article no. 3525611, 2021.

P. Twardowski, J. Czyżycki, A. Felusiak-Czyryca, M. Tabaszewski, and M. Wiciak-Pikuła, “Monitoring and Forecasting of Tool Wear Based on Measurements of Vibration Accelerations During Cast Iron Milling,” Journal of Manufacturing Processes, vol. 95, pp. 342-350, June 2023.

M. Jamshidi, X. Rimpault, M. Balazinski, and J. F. Chatelain, “Fractal Analysis Implementation for Tool Wear Monitoring Based on Cutting Force Signals During CFRP/Titanium Stack Machining,” The International Journal of Advanced Manufacturing Technology, vol. 106, no. 9-10, pp. 3859-3868, February 2020.

Z. Li, X. Liu, A. Incecik, M. K. Gupta, G. M. Królczyk, and P. Gardoni, “A Novel Ensemble Deep Learning Model for Cutting Tool Wear Monitoring Using Audio Sensors,” Journal of Manufacturing Processes, vol. 79, pp. 233-249, July 2022.

X. Zhou, T. Yu, G. Wang, R. Guo, Y. Fu, Y. Sun, et al., “Tool Wear Classification Based on Convolutional Neural Network and Time Series Images During High Precision Turning of Copper,” Wear, vol. 522, article no. 204692, June 2023.

M. Chen, M. Li, L. Zhao, and J. Liu, “Tool Wear Monitoring Based on the Combination of Machine Vision and Acoustic Emission,” The International Journal of Advanced Manufacturing Technology, vol. 125, no. 7-8, pp. 3881-3897, April 2023.

X. Li, A. Djordjevich, and P. K. Venuvinod, “Current-Sensor-Based Feed Cutting Force Intelligent Estimation and Tool Wear Condition Monitoring,” IEEE Transactions on Industrial Electronics, vol. 47, no. 3, pp. 697-702, June 2000.

K. Zhu, H. Guo, S. Li, and X. Lin, “Online Tool Wear Monitoring by Super-Resolution Based Machine Vision,” Computers in Industry, vol. 144, article no. 103782, January 2023.

Y. Li, X. Huang, J. Tang, S. Li, and P. Ding, “A Steps-Ahead Tool Wear Prediction Method Based on Support Vector Regression and Particle Filtering,” Measurement, vol. 218, article no. 113237, August 2023.

K. M. Li and Y. Y. Lin, “Tool Wear Classification in Milling for Varied Cutting Conditions: With Emphasis on Data Pre-Processing,” The International Journal of Advanced Manufacturing Technology, vol. 125, no. 1-2, pp. 341-355, March 2023.

Z. Xue, L. Li, Y. Wu, Y. Yang, W. Wu, Y. Zou, et al., “Study on Tool Wear State Recognition Algorithm Based on Spindle Vibration Signals Collected by Homemade Tool Condition Monitoring Ring,” Measurement, vol. 223, article no. 113787, December 2023.

A. Colpani, A. Fiorentino, E. Ceretti, and A. Attanasio, “Tool Wear Analysis in Micromilling of Titanium Alloy,” Precision Engineering, vol. 57, pp. 83-94, May 2019.

B. Zhang, L. Zhang, and J. Xu, “Degradation Feature Selection for Remaining Useful Life Prediction of Rolling Element Bearings,” Quality and Reliability Engineering International, vol. 32, no. 2, pp. 547-554, March 2016.

L. Colantonio, L. Equeter, P. Dehombreux, and F. Ducobu, “Comparison of Cutting Tool Wear Classification Performance with Artificial Intelligence Techniques,” Materials Research Proceedings, vol. 28, pp. 1265-1274, 2023.

V. Warke, S. Kumar, A. Bongale, and K. Kotecha, “Robust Tool Wear Prediction Using Multi-Sensor Fusion and Time-Domain Features for the Milling Process Using Instance-Based Domain Adaptation,” Knowledge-Based Systems, vol. 288, article no. 111454, March 2024.

M. Hu, W. Ming, Q. An, and M. Chen, “Tool Wear Monitoring in Milling of Titanium Alloy Ti–6Al–4 V Under MQL Conditions Based on a New Tool Wear Categorization Method,” The International Journal of Advanced Manufacturing Technology, vol. 104, no. 9-12, pp. 4117-4128, October 2019.

S. Y. Wong, J. H. Chuah, H. J. Yap, and C. F. Tan, “Dissociation Artificial Neural Network for Tool Wear Estimation in CNC Milling,” The International Journal of Advanced Manufacturing Technology, vol. 125, no. 1-2, pp. 887-901, March 2023.

J. Duan, J. Liang, X. Yu, Y. Si, X. Zhan, and T. Shi, “Toward Practical Tool Wear Prediction Paradigm with Optimized Regressive Siamese Neural Network,” Advanced Engineering Informatics, vol. 58, article no. 102200, October 2023.

J. He, Y. Sun, C. Yin, Y. He, and Y. Wang, “Cross-Domain Adaptation Network Based on Attention Mechanism for Tool Wear Prediction,” Journal of Intelligent Manufacturing, vol. 34, no. 8, pp. 3365-3387, December 2023.

J. Duan, X. Zhang, and T. Shi, “A Hybrid Attention-Based Paralleled Deep Learning Model for Tool Wear Prediction,” Expert Systems with Applications, vol. 211, article no. 118548, January 2023.

W. Yu, H. Huang, R. Guo, and P. Yang, “Tool Wear Prediction Based on Attention Long Short-Term Memory Network with Small Samples,” Sensors and Materials, vol. 35, no. 7(2), pp. 2321-2335, 2023.

G. Kim, S. M. Yang, S. Kim, D. Y. Kim, J. G. Choi, H. W. Park, et al., “A Multi-Domain Mixture Density Network for Tool Wear Prediction Under Multiple Machining Conditions,” International Journal of Production Research, in press. https://doi.org/10.1080/00207543.2023.2289076.

A. Vaswani, N. Shazeer, N. Parmar, J. Uszkoreit, L. Jones, A. N. Gomez, et al., “Attention Is All You Need,” https://doi.org/10.48550/arXiv.1706.03762, June 12, 2017.

“2010 PHM Society Conference Data Challenge,” https://phmsociety.org/phm_competition/2010-phm-society-conference-data-challenge, February 16, 2024.

Tool Life Testing in Milling— Part 2: End Milling, ISO 8688-2, 1989.

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Wanzhen Wang, Sze Song Ngu, Miaomiao Xin, Rong Liu, Qian Wang, Man Qiu, Shengqun Zhang

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)