Effect on Tool Design and Heat Input of Some Welding Parameters in Friction Stir Welded Interstitial Free Steels

Keywords:

friction stir welding (FSW), genetic algorithms, regression analysis.Abstract

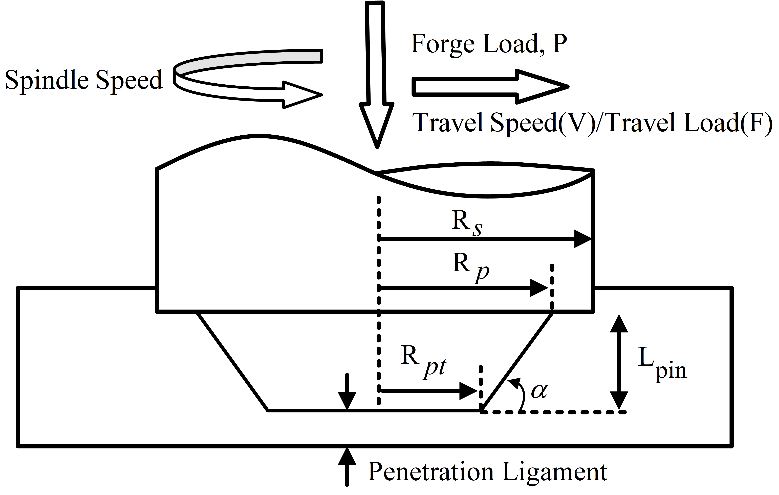

The friction stir welding process (FSW), a new solid state welding, are widely used in automobile and aerospace industries as compared to conventional fusion welding. The tool speed (rotational and translational), traverse speed, shoulder diameter and pin diameter are mainly responsible for the heat generation in FSW which are required to be optimized. The contribution of rotational tool speed is approximately three times higher than that of translational tool speed. This paper presents derivation for maximum heat generation to obtain best optimum tool geometry (tapered or cylindrical) in FSW through mathematical model using various parameters and necessary constraints. Two models namely genetic algorithm and regression model of response have been developed to compute optimum welding parameters. The genetic algorithm optimization technique has been employed for tapered and cylindrical FSW tool whereas the regression model has been employed for cylindrical FSW tool to obtain optimum tool geometry at constant welding speed. It has been found from genetic algorithm using MATLAB and regression modelling using MINITAB-17 that the optimum parameters for effective tool design are shoulder diameter as 12 mm, pin diameter as 4 mm and tool rotation speed as 250 rpm.

References

S. Hoile, “Processing and properties of mild interstitial free steels,” Materials Science and Technology, vol. 16, no. 10, pp. 1079-1093, October 2000.

Y. J. Chao, X. Qi, and W. Tang, “Heat transfer in friction stir welding: experimental and numerical studies,” Journal of Manufacturing Science and Engineering- Transactions of the ASME, vol. 125, no. 1, pp. 138-145, March 2003.

G. M. Reddy, “Friction stir welding,” NDT and Optimization, January 2014.

M. Mijajlovic and D. Milcic, “Analytical model for estimating the amount of heat generated during friction stir welding: Application on plates made of aluminium alloy 2024-T351,” Welding Processes, pp. 247-274, November 2012.

C. N. Suresha, B. M. Rajaprakash, and S. Upadhya, “A study of the effect of tool pin profiles on tensile strength of welded joints produced using friction stir welding process,” Materials Manufacturing, vol. 26, no. 9, pp. 1111-1116, June 2011.

D. G. Hattingh, C. Blignault, T. I. V. Niekerk, and M. N. James, “Characterization of the influences of FSW tool geometry on welding forces and weld tensile strength using an instrumented tool,” Journal of Material Production Technology, vol. 203, no. 1-3, pp. 46-70, July 2008.

G. Buffa, J. Hua, R. Shivpuri, and L. Fratini, “Design of the friction stir welding tool using the continuum based FEM model,” Materials Science and Engineering: A, vol. 419, no. 1-2, pp. 381-388, March 2006.

D. H. Lammlein, D. R. DeLapp, P. A. Fleming, A. M. Strauss, and G. E. Cook, “The application of shoulderless conical tools in friction stir welding: an experimental and theoretical study,” Materials & Design, vol. 30, no. 10, pp. 4012-4022, December 2009.

P. Biswas and N. R. Mandal, “Effect of tool geometries on thermal history of FSW of AA1100,” Weld Journal, vol. 90, pp. 129-135, July 2011.

R. Nandan, T. DebRoy, and H. K. D. H. Bhadeshia, “Recent advances in friction stir welding - Process, weldment structure and properties,” Process Mater Science, vol. 53, no. 6, pp. 980-1023, August 2008.

Y. Zhao,S. Lin, L. Wu, and F. Qu, “The Influence of Pin Geometry on Bonding and Mechanical Properties in Friction Stir Weld 2014 Al Alloy,” Materials Letters, vol. 59, no. 23, pp. 2948-2952, October 2005.

G. D. Shrikant and M. T. Shete, “Effect of various process parameters on friction stir welding,” International Journal of Research in Engineering and Technology, vol. 02, no. 12, pp. 555-558, December 2013.

R. Palanivel, P. K. Mathews, and N. Murugan, “Influences of tool pin profiles on the mechanical and metallurgical properties of FSW of dissimilar alloys,” International Journal of Engineering Science and Technology, vol. 2, no. 6, pp. 2109-2115, June 2010.

K. Elangovan and V. Balasubramanian, “Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminum alloy,” Materials Science and Engineering: A, vol. 459, no. 1-2, pp. 7-18, 2007.

K. Elangovan and V. Balasubramanian, “Influences of tool pin profile and welding speed on the formation of friction stir processing zone in AA2219 aluminum alloy,” Journal of Materials Processing Technology, vol. 200, no. 1-3, pp. 163-175, May 2008.

M. Z. H. Khandkar, J. A. Khan, and A. P. Reynolds, “Prediction of temperature distribution and thermal history during friction stir welding: input torque based model,” Science and Technology of Welding and Joining, vol. 8, no. 3, pp. 165-174, December 2003.

H. Schmidt, J. Hattel, and J. Wert, “An analytical model for the heat generation in friction stir welding,” Modelling Simul Mater Science Engineering, vol. 12, pp. 143-157, 2004.

P. Ulysse, “Three-dimensional modelling of the friction stir welding process,” International Journal of Mach Tools Manufacturing, vol. 42, no. 14, pp. 1549-1557, November 2002.

H. Shercliff and P. Colegrove, Modelling of friction stir welding in Mathematical Modelling of Weld Phenomena, pp. 927-974, London, Maney Publishing. 2002.

H. L. Hao, D. R. Ni, H. Huang, D. Wang, B. L. Xiao, Z. R. Nie, and Z. Y. Ma, “Effect of welding parameters on microstructure and mechanical properties of friction stir welded Al-Mg-Er alloy,” Materials Science and Engineering: A, vol. 559, pp. 889-896, January 2013.

W. J. Arbegast, “Modelling friction stir joining as a metal working process,” in “Hot Deformation of Aluminum Alloys,” Warrendale, PA, TMS, 2003.

M. Weglowski and A. Pietras, “Friction stir processing-analysis of the process,” Archives of Metallurgy and materials, vol. 56, no. 3, pp. 779-788, January 2011.

P. Edwards and M. Ramulu, “Effect of process conditions on superplastic forming behaviour in Ti-6Al-4V friction stir welds,” Science and Technology of Welding and Joining, vol. 14, no. 7, pp. 669-681, 2009.

P. Biswas and N. R. Mandal, “Effect of tool geometries on thermal history of FSW of AA1100,” Welding Journal, vol. 90, pp. 129-135, July 2011.

Z. Jurkovic, M. Brezocnik, and B. Grizelj, “Optimization of extrusion process by genetic algorithms and conventional techniques,” Tech Gaz, vol. 16, no. 4, pp. 27-33, December 2009.

K. Pathak, S. Lomash, and N. Jain, “Tube extrusion design for some selected inner profiles,” International Journal of Physical Sciences, vol. 4, no. 2, pp. 69-75, February 2009.

Y. J. Chao and X. Qi, “Thermal and thermos-mechanical modelling of friction stir welding of aluminum alloys 6061-T6,” Journal of Materials Processing and Manufacturing Science, vol. 7, pp. 215- 233, October 1998.

Additional Files

Published

How to Cite

Issue

Section

License

Copyright (c) 2017 International Journal of Engineering and Technology Innovation

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)