Engineering Properties of Ternary Cementless Blended Materials

DOI:

https://doi.org/10.46604/ijeti.2020.5201Keywords:

non-cement binder, co-fired fly ash, GGBS, chloride migration, green materialsAbstract

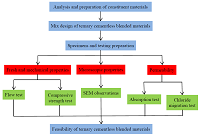

A new non-cement blended materials is developed as a full replacement of cement without alkali activator. This study was conducted to explore a suitable method for activating new ternary green materials with desulfurization gypsum, water-quenched blast-furnace slag and co-fired fly ash from circulating fluidized bed combustion as non-cement inorganic binder. Test subject was included flowability, compressive strength, absorption, total charge-passed from rapid chloride permeability test, chloride diffusion coefficient from accelerated chloride migration test and SEM observation. Test results indicate that a ternary mixture containing 1% desulfurization gypsum, 60% water-quenched blast-furnace slag and 39% co-fired fly ash was a suitable development in compressive strength. The new non-cement blended materials were performed a well compressive strength, lower absorption, and lower chloride diffusion coefficient. In addition, the compressive strength decreased as the inclusion of desulfurization gypsum increased. It was concluded that using desulfurization gypsum alone decreased the setting time and compressive strength. SEM micrographs were verified the development in compressive strength originated from the C-S-H and C-A-S-H gel produced by Ca(OH)2, SiO2, and Al2O3.

References

L. Zhang, C. He, A. Yang, Q. Yang, and J. Han, “Modeling and implication of coal physical input-output table in China—based on clean coal concept,” Resources, Conservation and Recycling, vol. 129, pp. 355-365, February 2018.

A. Hasan, M. G. Kibria, and F. M. M. Hasan, “Effects of incorporating recycled brick and stone aggregate as replacement of natural stone aggregate in concrete,” International Journal of Engineering and Technology Innovation, vol. 9, no. 1, pp. 38-48, January 2019.

J. Acordi, A. Luza, D. C. N. Fabris, F. Raupp-Pereira, A. De Noni Jr, and O. R. K. Montedo, “New waste-based supplementary cementitious materials: mortars and concrete formulations,” Construction and Building Materials, vol. 240, article 117877, April 2020.

W. T. Lin, “Characterization and permeability of cement-based materials containing calcium fluoride sludge,” Construction and Building Materials, vol. 196, pp. 564-573, January 2019.

R. M. Novais, J. Carvalheiras, L. Senff, A. M. Lacasta, I. R. Giro-Paloma, J. Giro-Paloma, et al., “Multifunctional cork – alkali-activated fly ash composites: a sustainable material to enhance buildings’ energy and acoustic performance,” Energy and Buildings, vol. 210, article 109739, March 2020.

N. Cristelo, J. Coelho, T. Miranda, Á. Palomo, and A. Fernández-Jiménez, “Alkali activated composites – an innovative concept using iron and steel slag as both precursor and aggregate,” Cement and Concrete Composites, vol. 103, pp. 11-21, October 2019.

C. C. Hung, Y. C. Wu, W. T. Lin, J. J. Chang, and W. C. Yeih, “Effect of mixture variables on durability for alkali-activated slag cementitious,” Materials, vol. 11, no. 11, article 2252, November 2018.

S. S. S. A. Nedunuri, S. G. Sertse, and S. Muhammad, “Microstructural study of portland cement partially replaced with fly ash, ground granulated blast furnace slag and silica fume as determined by pozzolanic activity,” Construction and Building Materials, vol. 238, article 117561, March 2020.

M. J. Moghadam, R. Ajalloeian, and A. Hajiannia, “Preparation and application of alkali-activated materials based on waste glass and coal gangue: a review,” Construction and Building Materials, vol. 221, pp. 84-98, October 2019.

T. Luukkonen, Z. Abdollahnejad, J. Yliniemi, M. Mastali, P. Kinnunen, and M. Illikainen, “Alkali-activated soapstone waste - mechanical properties, durability, and economic prospects,” Sustainable Materials and Technologies, vol. 22, article e00118, December 2019.

P. Awoyera and A. Adesina, “A critical review on application of alkali activated slag as a sustainable composite binder,” Case Studies in Construction Materials, vol. 11, article e00268, December 2019.

S. Luhar, T. W. Cheng, D. Nicolaides, I. Luhar, D. Panias, and K. Sakkas “Valorisation of glass wastes for the development of geopolymer composites – durability, thermal and microstructural properties: a review,” Construction and Building Materials, vol. 222, pp. 673-687, October 2019.

S. Badur and R. Chaudhary, “Utilization of hazardous wastes and by-products as a green concrete material through S/S process: a review,” Reviews on Advanced Materials Science, vol. 17, no. 1-2, pp. 42-61, 2008.

P. Asokan, M. Saxena, and S. R. Asolekar, “Hazardous jarosite use in developing non-hazardous product for engineering application,” vol. 137, no. 3, pp.1589-1599, October 2006.

A. A. Kadir, M. I. H. Hassan, and M. M. A. B. Abdullah, “Investigation on leaching behaviour of fly ash and bottom ash replacement in self-compacting concrete,” IOP Conference Series: Materials Science and Engineering, vol. 133, no. 1, p. 012036, June 2016.

A. A. Kadir, H. Hermawati, and A. S. Noor, “The utilization of coffee waste into fired clay brick,” ARPN Journal of Engineering and Applied Sciences, vol. 10, no. 15, pp. 6289-6292, 2015.

M. P Mubiayi, M. E Makhatha, and E. T Akinlabi, “Characterization, leachate characteristics and compressive strength of jarosite/clay/fly ash bricks,” Materials Today: Proceedings, vol. 5, no. 9, pp.17802-17811, 2018.

M. Katsioti, O. Mauridou, A. Moropoulou, E. Aggelakopoulou, P. E. Tsakiridis, S. Agatzini-Leonardou, et al., “Utilization of jarosite/alunite residue for mortars restoration production,” Materials and Structures, vol. 43, no. 1-2, pp.167-177, 2010.

A. A. Phul, M. J. Memon, S. N. R. Shah, and A. R. Sandhu, “GGBS and fly ash effects on compressive strength by partial replacement of cement concrete,” Civil Engineering Journal, vol. 5, no. 4, pp. 913-921, 2019.

A. M. Shihab, J. M. Abbas, and A. M. Ibrahim, “Effects of temperature in different initial duration time for soft clay stabilized by fly ash based geopolymer,” Civil Engineering Journal, vol. 4, no. 9, pp. 2082-2096, 2018.

W. Zhang, H. Choi, T. Sagawa, and Y. Hama, “Compressive strength development and durability of an environmental load-reduction material manufactured using circulating fluidized bed ash and blast-furnace slag,” Construction and Building Materials, vol. 146, pp. 102-113, August 2017.

H. A. Nguyen, T. P. Chang, J. W. Shih, C. T. Chen, and T. D. Nguyen, “Influence of circulating fluidized bed combustion (CFBC) fly ash on properties of modified high volume low calcium fly ash (HVFA) cement past,” Construction and Building Materials, vol. 91, pp. 208-215, August 2015.

M. Chi, “Synthesis and characterization of mortars with circulating fluidized bed combustion fly ash and ground granulated blast-furnace slag,” Construction and Building Materials, vol. 123, pp. 565-573, October 2016.

Y. H. Wu, R. Huang, C. J. Tsai, and W.T. Lin, “Utilizing residues of CFB co-combustion of coal, sludge and TDF as an alkali activator in eco-binder,” Construction and Building Materials, vol. 80, pp. 69-75, April 2015.

T. M. Do, G. Kang, and Y. Kim, “Development of a new cementless binder for controlled low strength material (CLSM) using entirely by-products,” Construction and Building Materials, vol.206, pp. 576-589, May 2019.

H. L. Ho, R. Huang, L. C. Hwang, W. T. Lin, and H. M. Hsu. “Waste-based pervious concrete for climate-resilient pavements,” Materials, vol. 11, no. 6, article 900, May 2018.

M. Chi and R. Huang, “Effect of circulating fluidized bed combustion ash on the properties of roller compacted concrete,” Cement and Concrete Composites, vol. 45, pp. 148-156, January 2014.

W. T. Lin, K. L. Lin, K. Chen, K. Korniejenko, M. Hebda, and M. Łach, “Circulation fluidized bed combustion fly ash as partial replacement of fine aggregates in roller compacted concrete,” Materials, vol. 12, no. 24, article 4208, December 2019.

A. Quennoz and K. L. Scrivener, “Hydration of C3A-gypsum systems,” Cement and Concrete Research, vol. 42, no. 7, pp. 1032-1041, July 2012.

M. C. Caillahua and F. J. Moura, “Technical feasibility for use of FGD gypsum as an additive setting time retarder for Portland cement,” Journal of Materials Research and Technology, vol. 7, no. 2, pp. 190-197, April-June 2018.

W. T. Lin, K. L. Lin, K. Korniejenko, L. Fiala, A. Cheng, and J. Chen, “Composite properties of non-cement blended fiber composites without alkali activator,” Materials, vol. 13, no. 6, article 1443, March 2020.

V. Kočí, M. Petříková, J. Fořt, L. Fiala, and R. Černý, “Preparation of self-heating alkali-activated materials using industrial waste products,” Journal of Cleaner Production, vol. 260, article 121116, July 2020.

M. Inoue, H. Choi, and Y. Sudoh, “Fresh properties and strength development of cement mortar using nitrite-based accelerator and chemical admixtures,” Proceedings of Engineering and Technology Innovation, vol. 9, pp. 9-16, July 2018.

S. Wansom, P. Chintasongkro, and W. Srijampan, “Water resistant blended cements containing flue-gas desulfurization gypsum, Portland cement and fly ash for structural applications,” Cement and Concrete Composites, vol. 103, pp. 134-148, October 2019.

E. J. Anthony, L. Jia, and Y. Wu, “CFBC ash hydration studies,” Fuel, vol. 84, no. 11, pp. 1393-1397, August 2005.

K. L. Lin, T. W. Cheng, C. H. Ho, Y. M. Chang, and K. W. Lo, “Utilization of circulating fluidized bed fly ash as pozzolanic material,” The Open Civil Engineering Journal, vol. 11, no. 1, pp. 176-186, 2017.

C. Baek, J. Seo, M. Choi, J. Cho, J. Ahn, and K. Cho, “Utilization of CFBC fly ash as a binder to produce in-furnace desulfurization sorbent,” Sustainability, vol. 10, no. 12, article 4854, December 2018.

Published

How to Cite

Issue

Section

License

Copyright Notice

Submission of a manuscript implies: that the work described has not been published before that it is not under consideration for publication elsewhere; that if and when the manuscript is accepted for publication. Authors can retain copyright in their articles with no restrictions. Also, author can post the final, peer-reviewed manuscript version (postprint) to any repository or website.

Since Jan. 01, 2019, IJETI will publish new articles with Creative Commons Attribution Non-Commercial License, under Creative Commons Attribution Non-Commercial 4.0 International (CC BY-NC 4.0) License.

The Creative Commons Attribution Non-Commercial (CC-BY-NC) License permits use, distribution and reproduction in any medium, provided the original work is properly cited and is not used for commercial purposes.

.jpg)